Related Research Articles

An electric motor is an electrical machine that converts electrical energy into mechanical energy. Most electric motors operate through the interaction between the motor's magnetic field and electric current in a wire winding to generate force in the form of torque applied on the motor's shaft. An electric generator is mechanically identical to an electric motor, but operates with a reversed flow of power, converting mechanical energy into electrical energy.

Aircraft engine controls provide a means for the pilot to control and monitor the operation of the aircraft's powerplant. This article describes controls used with a basic internal-combustion engine driving a propeller. Some optional or more advanced configurations are described at the end of the article. Jet turbine engines use different operating principles and have their own sets of controls and sensors.

As used in mechanical engineering, the term tractive force can either refer to the total traction a vehicle exerts on a surface, or the amount of the total traction that is parallel to the direction of motion.

Dynamic braking is the use of an electric traction motor as a generator when slowing a vehicle such as an electric or diesel-electric locomotive. It is termed "rheostatic" if the generated electrical power is dissipated as heat in brake grid resistors, and "regenerative" if the power is returned to the supply line. Dynamic braking reduces wear on friction-based braking components, and regeneration lowers net energy consumption. Dynamic braking may also be used on railcars with multiple units, light rail vehicles, electric trams, trolleybuses, and electric and hybrid electric automobiles.

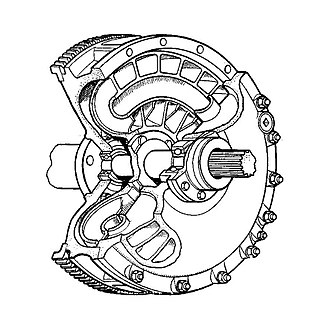

A torque converter is a type of fluid coupling that transfers rotating power from a prime mover, like an internal combustion engine, to a rotating driven load. In a vehicle with an automatic transmission, the torque converter connects the power source to the load. It is usually located between the engine's flexplate and the transmission. The equivalent location in a manual transmission would be the mechanical clutch.

Propulsion transmission is the mode of transmitting and controlling propulsion power of a machine. The term transmission properly refers to the whole drivetrain, including clutch, gearbox, prop shaft, differential, and final drive shafts. In the United States the term is sometimes used in casual speech to refer more specifically to the gearbox alone, and detailed usage differs. The transmission reduces the higher engine speed to the slower wheel speed, increasing torque in the process. Transmissions are also used on pedal bicycles, fixed machines, and where different rotational speeds and torques are adapted.

A continuously variable transmission (CVT) is an automatic transmission that can change seamlessly through a continuous range of gear ratios. This contrasts with other transmissions that provide a limited number of gear ratios in fixed steps. The flexibility of a CVT with suitable control may allow the engine to operate at a constant RPM while the vehicle moves at varying speeds.

A brushless DC electric motor, also known as an electronically commutated motor or synchronous DC motor, is a synchronous motor using a direct current (DC) electric power supply. It uses an electronic controller to switch DC currents to the motor windings producing magnetic fields which effectively rotate in space and which the permanent magnet rotor follows. The controller adjusts the phase and amplitude of the DC current pulses to control the speed and torque of the motor. This control system is an alternative to the mechanical commutator (brushes) used in many conventional electric motors.

A dynamometer or "dyno" for short, is a device for simultaneously measuring the torque and rotational speed (RPM) of an engine, motor or other rotating prime mover so that its instantaneous power may be calculated, and usually displayed by the dynamometer itself as kW or bhp.

A traction motor is an electric motor used for propulsion of a vehicle, such as locomotives, electric or hydrogen vehicles, elevators or electric multiple unit.

The universal motor is a type of electric motor that can operate on either AC or DC power and uses an electromagnet as its stator to create its magnetic field. It is a commutated series-wound motor where the stator's field coils are connected in series with the rotor windings through a commutator. It is often referred to as an AC series motor. The universal motor is very similar to a DC series motor in construction, but is modified slightly to allow the motor to operate properly on AC power. This type of electric motor can operate well on AC because the current in both the field coils and the armature will alternate synchronously with the supply. Hence the resulting mechanical force will occur in a consistent direction of rotation, independent of the direction of applied voltage, but determined by the commutator and polarity of the field coils.

Motor drive means a system that includes a motor. An adjustable speed motor drive means a system that includes a motor that has multiple operating speeds. A variable speed motor drive is a system that includes a motor and is continuously variable in speed. If the motor is generating electrical energy rather than using it – this could be called a generator drive but is often still referred to as a motor drive.

A fluid coupling or hydraulic coupling is a hydrodynamic or 'hydrokinetic' device used to transmit rotating mechanical power. It has been used in automobile transmissions as an alternative to a mechanical clutch. It also has widespread application in marine and industrial machine drives, where variable speed operation and controlled start-up without shock loading of the power transmission system is essential.

The power band of an internal combustion engine or electric motor is the range of operating speeds under which the engine or motor is able to output the most power, that is, the maximum energy per unit of time. This usually means that maximum acceleration can be achieved inside this band. While engines and motors have a large range of operating speeds, the power band is usually a much smaller range of engine speed, only half or less of the total engine speed range.

An AC motor is an electric motor driven by an alternating current (AC). The AC motor commonly consists of two basic parts, an outside stator having coils supplied with alternating current to produce a rotating magnetic field, and an inside rotor attached to the output shaft producing a second rotating magnetic field. The rotor magnetic field may be produced by permanent magnets, reluctance saliency, or DC or AC electrical windings.

A torque motor is a specialized form of DC electric motor which can operate indefinitely while stalled, without incurring damage. In this mode of operation, the motor will apply a steady torque to the load. A torque motor that cannot perform a complete rotation is known as a limited angle torque motor. Brushless torque motors are available; elimination of commutators and brushes allows higher speed operation.

A hydraulic motor is a mechanical actuator that converts hydraulic pressure and flow into torque and angular displacement (rotation). The hydraulic motor is the rotary counterpart of the hydraulic cylinder as a linear actuator. Most broadly, the category of devices called hydraulic motors has sometimes included those that run on hydropower but in today's terminology the name usually refers more specifically to motors that use hydraulic fluid as part of closed hydraulic circuits in modern hydraulic machinery.

An induction generator or asynchronous generator is a type of alternating current (AC) electrical generator that uses the principles of induction motors to produce electric power. Induction generators operate by mechanically turning their rotors faster than synchronous speed. A regular AC induction motor usually can be used as a generator, without any internal modifications. Because they can recover energy with relatively simple controls, induction generators are useful in applications such as mini hydro power plants, wind turbines, or in reducing high-pressure gas streams to lower pressure.

A brushed DC electric motor is an internally commutated electric motor designed to be run from a direct current power source and utilizing an electric brush for contact.

A rotary actuator is an actuator that produces a rotary motion or torque.

References

- ↑ "How to Determine What Torque You Need for Your Servo Motors". Automatic Addison. 2020-10-11.

- ↑ Johns, W. E. (20 April 2010). "Notes on Motors".

- 1 2 Thacher, Eric F. (2003). A Solar Car Primer. Nova Science Publishers. p. 86. ISBN 978-1-59033-308-2.