Filtration is a physical separation process that separates solid matter and fluid from a mixture using a filter medium that has a complex structure through which only the fluid can pass. Solid particles that cannot pass through the filter medium are described as oversize and the fluid that passes through is called the filtrate. Oversize particles may form a filter cake on top of the filter and may also block the filter lattice, preventing the fluid phase from crossing the filter, known as blinding. The size of the largest particles that can successfully pass through a filter is called the effective pore size of that filter. The separation of solid and fluid is imperfect; solids will be contaminated with some fluid and filtrate will contain fine particles. Filtration occurs both in nature and in engineered systems; there are biological, geological, and industrial forms.

High-performance liquid chromatography (HPLC), formerly referred to as high-pressure liquid chromatography, is a technique in analytical chemistry used to separate, identify, and quantify specific components in mixtures. The mixtures can originated from food, chemicals, pharmaceuticals, biological, environmental and agriculture, etc, which have been dissolved into liquid solutions. It relies on high pressure pumps, which deliver mixtures of various solvents, called the mobile phase, which flows through the system, collecting the sample mixture on the way, delivering it into a cylinder, called the column, filled with solid particles, made of adsorbent material, called the stationary phase. Each component in the sample interacts slightly different with the adsorbent material, causing different migration rate for the each component, leading to their separation, as they flow out of the column into a specific detector. The output of the detector is a graph, called Chromatogram. Chromatograms are graphical representations of the signal intensity versus time or volume, showing peaks, which represent components of the sample, each appears in its respective time, called Retention Time, having area proportional to its amount.

Filter paper is a semi-permeable paper barrier placed perpendicular to a liquid or air flow. It is used to separate fine solid particles from liquids or gases.

A cleanroom or clean room is an engineered space, which maintains a very low concentration of airborne particulates. It is well isolated, well-controlled from contamination, and actively cleansed. Such rooms are commonly needed for scientific research, and in industrial production for all nanoscale processes, such as semiconductor manufacturing. A cleanroom is designed to keep everything from dust, to airborne organisms, or vaporised particles, away from it, and so from whatever material is being handled inside it.

Ultrafiltration (UF) is a variety of membrane filtration in which forces such as pressure or concentration gradients lead to a separation through a semipermeable membrane. Suspended solids and solutes of high molecular weight are retained in the so-called retentate, while water and low molecular weight solutes pass through the membrane in the permeate (filtrate). This separation process is used in industry and research for purifying and concentrating macromolecular (103–106 Da) solutions, especially protein solutions.

Microfiltration is a type of physical filtration process where a contaminated fluid is passed through a special pore-sized membrane filter to separate microorganisms and suspended particles from process liquid. It is commonly used in conjunction with various other separation processes such as ultrafiltration and reverse osmosis to provide a product stream which is free of undesired contaminants.

Sterilization refers to any process that removes, kills, or deactivates all forms of life and other biological agents such as prions present in or on a specific surface, object, or fluid. Sterilization can be achieved through various means, including heat, chemicals, irradiation, high pressure, and filtration. Sterilization is distinct from disinfection, sanitization, and pasteurization, in that those methods reduce rather than eliminate all forms of life and biological agents present. After sterilization, an object is referred to as being sterile or aseptic.

HEPA filter, also known as high-efficiency particulate absorbing filter and high-efficiency particulate arrestance filter, is an efficiency standard of air filters.

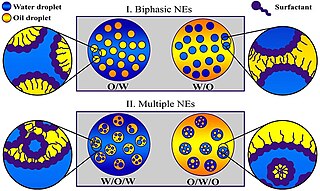

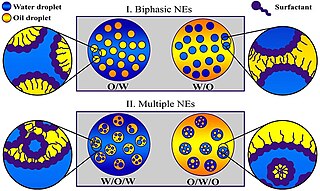

A miniemulsion is a particular type of emulsion. A miniemulsion is obtained by shearing a mixture comprising two immiscible liquid phases, one or more surfactants and, possibly, one or more co-surfactants. They usually have nanodroplets with uniform size distribution and are also known as sub-micron, mini-, and ultra-fine grain emulsions.

In chemical engineering, biochemical engineering and protein purification, crossflow filtration is a type of filtration. Crossflow filtration is different from dead-end filtration in which the feed is passed through a membrane or bed, the solids being trapped in the filter and the filtrate being released at the other end. Cross-flow filtration gets its name because the majority of the feed flow travels tangentially across the surface of the filter, rather than into the filter. The principal advantage of this is that the filter cake is substantially washed away during the filtration process, increasing the length of time that a filter unit can be operational. It can be a continuous process, unlike batch-wise dead-end filtration.

Merck Millipore was the brand used by Merck Group's global life science business until 2015 when the company re-branded. It was formed when Merck acquired the Millipore Corporation in 2010. Merck is a supplier to the life science industry. The Millipore Corporation was founded in 1954, and listed among the S&P 500 since the early 1990s, as an international biosciences company which makes micrometer pore-size filters and tests. In 2015, Merck acquired Sigma-Aldrich and merged it with Merck Millipore. In the United States and Canada, the life science business is now known as MilliporeSigma.

Depth filters are filters that use a porous filtration medium to retain particles throughout the medium, rather than just on the surface of the medium. Depth filtration, typified by multiple porous layers with depth, is used to capture the solid contaminants from the liquid phase. These filters are commonly used when the fluid to be filtered contains a high load of particles because, relative to other types of filters, they can retain a large mass of particles before becoming clogged.

A vacuum ceramic filter is designed to separate liquids from solids for dewatering of ore concentrates purposes. The device consists of a rotator, slurry tank, ceramic filter plate, distributor, discharge scraper, cleaning device, frame, agitating device, pipe system, vacuum system, automatic acid dosing system, automatic lubricating system, valve and discharge chute. The operation and construction principle of vacuum ceramic filter resemble those of a conventional disc filter, but the filter medium is replaced by a finely porous ceramic disc. The disc material is inert, has a long operational life and is resistant to almost all chemicals. Performance can be optimized by taking into account all those factors which affect the overall efficiency of the separation process. Some of the variables affecting the performance of a vacuum ceramic filter include the solid concentration, speed rotation of the disc, slurry level in the feed basin, temperature of the feed slurry, and the pressure during dewatering stages and filter cake formation.

A monolithic HPLC column, or monolithic column, is a column used in high-performance liquid chromatography (HPLC). The internal structure of the monolithic column is created in such a way that many channels form inside the column. The material inside the column which separates the channels can be porous and functionalized. In contrast, most HPLC configurations use particulate packed columns; in these configurations, tiny beads of an inert substance, typically a modified silica, are used inside the column. Monolithic columns can be broken down into two categories, silica-based and polymer-based monoliths. Silica-based monoliths are known for their efficiency in separating smaller molecules while, polymer-based are known for separating large protein molecules.

A membrane is a selective barrier; it allows some things to pass through but stops others. Such things may be molecules, ions, or other small particles. Membranes can be generally classified into synthetic membranes and biological membranes. Biological membranes include cell membranes ; nuclear membranes, which cover a cell nucleus; and tissue membranes, such as mucosae and serosae. Synthetic membranes are made by humans for use in laboratories and industry.

Ultrapure water (UPW), high-purity water or highly purified water (HPW) is water that has been purified to uncommonly stringent specifications. Ultrapure water is a term commonly used in manufacturing to emphasize the fact that the water is treated to the highest levels of purity for all contaminant types, including: organic and inorganic compounds; dissolved and particulate matter; volatile and non-volatile; reactive, and inert; hydrophilic and hydrophobic; and dissolved gases.

Membrane technology encompasses the scientific processes used in the construction and application of membranes. Membranes are used to facilitate the transport or rejection of substances between mediums, and the mechanical separation of gas and liquid streams. In the simplest case, filtration is achieved when the pores of the membrane are smaller than the diameter of the undesired substance, such as a harmful microorganism. Membrane technology is commonly used in industries such as water treatment, chemical and metal processing, pharmaceuticals, biotechnology, the food industry, as well as the removal of environmental pollutants.

Bioburden is normally defined as the number of bacteria living on a surface that has not been sterilized.

Perstraction is a membrane extraction process, where two liquid phases are contacted across a membrane. The desired species in the feed (solute), selectively crosses the membrane into the extracting solution. Perstraction was originally developed to overcome the downsides of liquid–liquid extraction, for example extractant toxicity and emulsion formation. Perstraction has been applied to many fields including fermentation, waste water treatment and alcohol-free beverage production.

A liposome extruder is a device that prepares cell membranes, exosomes and also generates nanoscale liposome formulations. The liposome extruder employs the track-etched membrane to filter huge particles and achieve sterile filtration.