The field of electronics is a branch of physics and electrical engineering that deals with the emission, behaviour and effects of electrons using electronic devices. Electronics uses active devices to control electron flow by amplification and rectification, which distinguishes it from classical electrical engineering, which only uses passive effects such as resistance, capacitance and inductance to control electric current flow.

Mechanical engineering is an engineering branch that combines engineering physics and mathematics principles with materials science, to design, analyze, manufacture, and maintain mechanical systems. It is one of the oldest and broadest of the engineering branches.

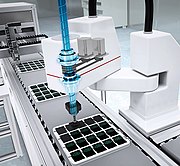

Automation describes a wide range of technologies that reduce human intervention in processes, namely by predetermining decision criteria, subprocess relationships, and related actions, as well as embodying those predeterminations in machines. Automation has been achieved by various means including mechanical, hydraulic, pneumatic, electrical, electronic devices, and computers, usually in combination. Complicated systems, such as modern factories, airplanes, and ships typically use combinations of all of these techniques. The benefit of automation includes labor savings, reducing waste, savings in electricity costs, savings in material costs, and improvements to quality, accuracy, and precision.

Mechatronics, also called mechatronics engineering, is an interdisciplinary branch of engineering that focuses on the integration of mechanical, electrical and electronic engineering systems, and also includes a combination of robotics, electronics, computer science, telecommunications, systems, control, and product engineering.

Teradyne, Inc. is an American automatic test equipment (ATE) designer and manufacturer based in North Reading, Massachusetts. Teradyne's high-profile customers include Samsung, Qualcomm, Intel, Analog Devices, Texas Instruments and IBM.

FANUC is a Japanese group of companies that provide automation products and services such as robotics and computer numerical control wireless systems. These companies are principally FANUC Corporation of Japan, Fanuc America Corporation of Rochester Hills, Michigan, USA, and FANUC Europe Corporation S.A. of Luxembourg.

James E. Solomon is an American engineer and entrepreneur. In his lifetime, he has founded four companies, including one of the companies that merged to form the leading chip manufacturing toolmaker Cadence Design Systems. He is an IEEE Fellow and received the industry's Phil Kaufman Award in 1997. Solomon holds 23 patents in integrated chip design.

Murata Machinery, Ltd., abbrev. MML, is a privately held Japanese international company founded in 1935 with its Head Office at Fushimi-ku, Kyoto

Integrated Micro-electronics, Inc. provides electronics manufacturing services (EMS) and power semiconductor assembly and test services (SATS) with manufacturing facilities in Asia, Europe, and North America. Its headquarters is located in Biñan, Laguna, Philippines.

The following outline is provided as an overview of and topical guide to automation:

Manufacturing engineering or production engineering is a branch of professional engineering that shares many common concepts and ideas with other fields of engineering such as mechanical, chemical, electrical, and industrial engineering. Manufacturing engineering requires the ability to plan the practices of manufacturing; to research and to develop tools, processes, machines and equipment; and to integrate the facilities and systems for producing quality products with the optimum expenditure of capital.

The Westinghouse Brake & Signal Company Ltd was a British manufacturer of railroad signs. Founded by George Westinghouse, it was registered as "Westinghouse Brake Company" in 1881. The company reorganised in 1920, associating with Evans O'Donnell, and Saxby and Farmer which merged to form the "Westinghouse Brake & Saxby Signal Company". The 'Saxby' would be dropped from their title in 1935.

Vibratory bowl feeders, also known as a bowl feeders, are common devices used to orient and feed individual component parts for assembly on industrial production lines. They are used when a randomly sorted bulk package of small components must be fed into another machine one-by-one, oriented in a particular direction.

RNA Automation, a member of Rhein-Nadel Automation, was established in Birmingham UK in 1986, and has progressed into becoming the major supplier of parts handling equipment in the UK. The company operates in the area of specialised Automation engineering, providing automatic parts handling equipment for high volume production in the cosmetics, pharmaceutical, electronics, food and metal working industries, with seven manufacturing facilities across Europe and North America and a network of sales and service outlets across the globe.

PAR Systems, Inc, is a systems engineering firm headquartered in Shoreview, Minnesota, specializing in automated manufacturing and material handling equipment. subsidiaries include Jered LLC, specializing in marine equipment and cargo handling systems; Ederer LLC, specializing in custom and specialty cranes and associated equipment; CAMotion, specializing in advanced motion control and Cartesian palletizers and Oak River Technology, specializing in automated manufacturing, testing equipment and medical device manufacturing equipment. PAR systems specializes in engineering equipment for the nuclear field, designing equipment for nuclear industry hot cells, process facilities and decommissioning applications in Japan, UK and United States. In the aerospace industry, PAR specializes in precision cutting, trimming, drilling, coating, scanning and non-destructive testing equipment PAR Systems has quality certifications in ISO9001, AS9100, ISO13485 and ASME NQA-1 compliant.

Industrial and production engineering (IPE) is an interdisciplinary engineering discipline that includes manufacturing technology, engineering sciences, management science, and optimization of complex processes, systems, or organizations. It is concerned with the understanding and application of engineering procedures in manufacturing processes and production methods. Industrial engineering dates back all the way to the industrial revolution, initiated in 1700s by Sir Adam Smith, Henry Ford, Eli Whitney, Frank Gilbreth and Lilian Gilbreth, Henry Gantt, F.W. Taylor, etc. After the 1970s, industrial and production engineering developed worldwide and started to widely use automation and robotics. Industrial and production engineering includes three areas: Mechanical engineering, industrial engineering, and management science.

Automation technicians repair and maintain the computer-controlled systems and robotic devices used within industrial and commercial facilities to reduce human intervention and maximize efficiency. Their duties require knowledge of electronics, mechanics and computers. Automation technicians perform routine diagnostic checks on automated systems, monitor automated systems, isolate problems and perform repairs. If a problem occurs, the technician needs to be able to troubleshoot the issue and determine if the problem is mechanical, electrical or from the computer systems controlling the process. Once the issue has been diagnosed, the technician must repair or replace any necessary components, such as a sensor or electrical wiring. In addition to troubleshooting, Automation technicians design and service control systems ranging from electromechanical devices and systems to high-speed robotics and programmable logic controllers (PLCs). These types of systems include robotic assembly devices, conveyors, batch mixers, electrical distribution systems, and building automation systems. These machines and systems are often found within industrial and manufacturing plants, such as food processing facilities. Alternate job titles include field technician, bench technician, robotics technician, PLC technician, production support technician and maintenance technician.

Anwar Chitayat is the founder and former CEO and chairman of Anorad Corp., which was acquired in 1998 by Rockwell Automation. Mr. Chitayat holds over 95 patents in Electronics, Semiconductors and Automation including Nanotechnology, Interferometry and Linear motors. His achievements in High technology were honored by SEMI at their highest honor for Lifetime Achievement, reserved for individuals who repeatedly enable and lead the technology industry throughout their professional career. In the year 1997, Anwar was awarded the Entrepreneur of the year award by Ernst and Young, and in the year 2009, Anwar was inducted to Long Island Hall of Fame for his impacts on science and technology on Long Island.

Boaz Eidelberg, Ph.D. is an inventor of multiple patents in robotics and high performance positioning systems, including their mechatronics system analysis tools for design optimization.

A high performance positioning system (HPPS) is a type of positioning system consisting of a piece of electromechanics equipment that is capable of moving an object in a three-dimensional space within a work envelope. Positioning could be done point to point or along a desired path of motion. Position is typically defined in six degrees of freedom, including linear, in an x,y,z cartesian coordinate system, and angular orientation of yaw, pitch, roll. HPPS are used in many manufacturing processes to move an object smoothly and accurately in six degrees of freedom, along a desired path, at a desired orientation, with high acceleration, high deceleration, high velocity and low settling time. It is designed to quickly stop its motion and accurately place the moving object at its desired final position and orientation with minimal jittering.