A thermometer is a device that measures temperature or temperature gradient. A thermometer has two important elements: (1) a temperature sensor in which some change occurs with a change in temperature; and (2) some means of converting this change into a numerical value. Thermometers are widely used in technology and industry to monitor processes, in meteorology, in medicine, and in scientific research.

Luminescence is the "spontaneous emission of radiation from an electronically excited species not in thermal equilibrium with its environment", according to the IUPAC definition. A luminescent object is emitting "cold light", in contrast to "incandescence", where an object only emits light after heating. Generally, the emission of light is due to the movement of electrons between different energy levels within an atom after excitation by external factors. However, the exact mechanism of light emission in "vibrationally excited species" is unknown, as seen in sonoluminescence.

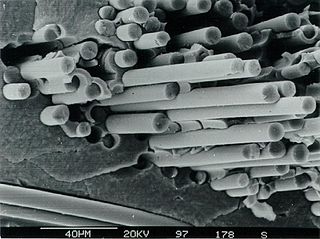

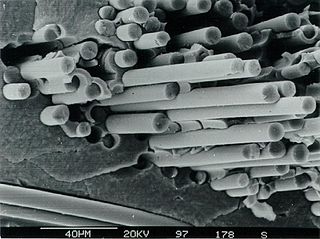

A phosphor is a substance that exhibits the phenomenon of luminescence; it emits light when exposed to some type of radiant energy. The term is used both for fluorescent or phosphorescent substances which glow on exposure to ultraviolet or visible light, and cathodoluminescent substances which glow when struck by an electron beam in a cathode-ray tube.

Zirconium dioxide is a white crystalline oxide of zirconium. Its most naturally occurring form, with a monoclinic crystalline structure, is the mineral baddeleyite. A dopant stabilized cubic structured zirconia, cubic zirconia, is synthesized in various colours for use as a gemstone and a diamond simulant.

In engineering, a heat shield is a component designed to protect an object or a human operator from being burnt or overheated by dissipating, reflecting, and/or absorbing heat. The term is most often used in reference to exhaust heat management and to systems for dissipating frictional heat. Heat shields are used most commonly in automotive and aerospace.

Yttrium aluminium garnet (YAG, Y3Al5O12) is a synthetic crystalline material of the garnet group. It is a cubic yttrium aluminium oxide phase, with other examples being YAlO3 (YAP) in a hexagonal or an orthorhombic, perovskite-like form, and the monoclinic Y4Al2O9 (YAM).

A superalloy, or high-performance alloy, is an alloy with the ability to operate at a high fraction of its melting point. Key characteristics of a superalloy include mechanical strength, thermal creep deformation resistance, surface stability, and corrosion and oxidation resistance.

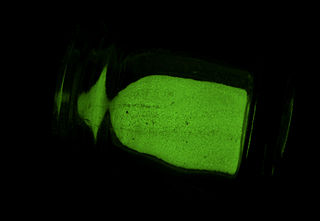

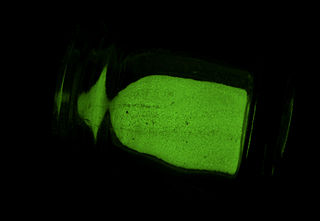

Phosphor thermometry is an optical method for surface temperature measurement. The method exploits luminescence emitted by phosphor material. Phosphors are fine white or pastel-colored inorganic powders which may be stimulated by any of a variety of means to luminesce, i.e. emit light. Certain characteristics of the emitted light change with temperature, including brightness, color, and afterglow duration. The latter is most commonly used for temperature measurement.

Ceramic engineering is the science and technology of creating objects from inorganic, non-metallic materials. This is done either by the action of heat, or at lower temperatures using precipitation reactions from high-purity chemical solutions. The term includes the purification of raw materials, the study and production of the chemical compounds concerned, their formation into components and the study of their structure, composition and properties.

Conformal coating is a protective, breathable coating of thin polymeric film applied to printed circuit boards (PCBs). Conformal coatings are typically applied at 25–250 μm to the electronic circuitry and provide protection against moisture and other harsher conditions.

Thermal spraying techniques are coating processes in which melted materials are sprayed onto a surface. The "feedstock" is heated by electrical or chemical means.

Thermal barrier coatings (TBCs) are advanced materials systems usually applied to metallic surfaces on parts operating at elevated temperatures, such as gas turbine combustors and turbines, and in automotive exhaust heat management. These 100 μm to 2 mm thick coatings of thermally insulating materials serve to insulate components from large and prolonged heat loads and can sustain an appreciable temperature difference between the load-bearing alloys and the coating surface. In doing so, these coatings can allow for higher operating temperatures while limiting the thermal exposure of structural components, extending part life by reducing oxidation and thermal fatigue. In conjunction with active film cooling, TBCs permit working fluid temperatures higher than the melting point of the metal airfoil in some turbine applications. Due to increasing demand for more efficient engines running at higher temperatures with better durability/lifetime and thinner coatings to reduce parasitic mass for rotating/moving components, there is significant motivation to develop new and advanced TBCs. The material requirements of TBCs are similar to those of heat shields, although in the latter application emissivity tends to be of greater importance.

Gas dynamic cold spraying or cold spraying (CS) is a coating deposition method. Solid powders are accelerated in a supersonic gas jet to velocities up to ca. 1200 m/s. During impact with the substrate, particles undergo plastic deformation and adhere to the surface. To achieve a uniform thickness the spraying nozzle is scanned along the substrate. Metals, polymers, ceramics, composite materials and nanocrystalline powders can be deposited using cold spraying. The kinetic energy of the particles, supplied by the expansion of the gas, is converted to plastic deformation energy during bonding. Unlike thermal spraying techniques, e.g., plasma spraying, arc spraying, flame spraying, or high velocity oxygen fuel (HVOF), the powders are not melted during the spraying process.

An abradable coating is a coating made of an abradable material – meaning if it rubs against a more abrasive material in motion, the former will be worn whereas the latter will face no wear. Abradable coatings provide a .1 to .2% performance improvement compared to those without coating.

Electrostatic spray-assisted vapour deposition (ESAVD) is a technique to deposit both thin and thick layers of a coating onto various substrates. In simple terms chemical precursors are sprayed across an electrostatic field towards a heated substrate, the chemicals undergo a controlled chemical reaction and are deposited on the substrate as the required coating. Electrostatic spraying techniques were developed in the 1950s for the spraying of ionised particles on to charged or heated substrates.

Yttria-stabilized zirconia (YSZ) is a ceramic in which the cubic crystal structure of zirconium dioxide is made stable at room temperature by an addition of yttrium oxide. These oxides are commonly called "zirconia" (ZrO2) and "yttria" (Y2O3), hence the name.

A turbine blade is a radial aerofoil mounted in the rim of a turbine disc and which produces a tangential force which rotates a turbine rotor. Each turbine disc has many blades. As such they are used in gas turbine engines and steam turbines. The blades are responsible for extracting energy from the high temperature, high pressure gas produced by the combustor. The turbine blades are often the limiting component of gas turbines. To survive in this difficult environment, turbine blades often use exotic materials like superalloys and many different methods of cooling that can be categorized as internal and external cooling, and thermal barrier coatings. Blade fatigue is a major source of failure in steam turbines and gas turbines. Fatigue is caused by the stress induced by vibration and resonance within the operating range of machinery. To protect blades from these high dynamic stresses, friction dampers are used.

In materials science ceramic matrix composites (CMCs) are a subgroup of composite materials and a subgroup of ceramics. They consist of ceramic fibers embedded in a ceramic matrix. The fibers and the matrix both can consist of any ceramic material, including carbon and carbon fibers.

Titanium in zircon geothermometry is a form of a geothermometry technique by which the crystallization temperature of a zircon crystal can be estimated by the amount of titanium atoms which can only be found in the crystal lattice. In zircon crystals, titanium is commonly incorporated, replacing similarly charged zirconium and silicon atoms. This process is relatively unaffected by pressure and highly temperature dependent, with the amount of titanium incorporated rising exponentially with temperature, making this an accurate geothermometry method. This measurement of titanium in zircons can be used to estimate the cooling temperatures of the crystal and infer conditions during which it crystallized. Compositional changes in the crystals growth rings can be used to estimate the thermodynamic history of the entire crystal. This method is useful as it can be combined with radiometric dating techniques that are commonly used with zircon crystals, to correlate quantitative temperature measurements with specific absolute ages. This technique can be used to estimate early Earth conditions, determine metamorphic facies, or to determine the source of detrital zircons, among other uses.

Detonation spraying is one of the many forms of thermal spraying techniques that are used to apply a protective coating at supersonic velocities to a material in order to change its surface characteristics. This is primarily to improve the durability of a component. It was first invented in 1955 by H.B. Sargent, R.M. Poorman and H. Lamprey and is applied to a component using a specifically designed detonation gun (D-gun). The component being sprayed must be prepared correctly by removing all surface oils, greases, debris and roughing up the surface in order to achieve a strongly bonded detonation spray coating. This process involves the highest velocities and temperatures (≈4000 °C) of coating materials compared to all other forms of thermal spraying techniques. Which means detonation spraying is able to apply low porous and low oxygen content protective coatings that protect against corrosion, abrasion and adhesion under low load.