Description

The engine has near isothermal cylinders because 1) the heater area covers the entire cylinder end, 2) it is a short stroke device, with wide shallow cylinders, yielding a high surface area to volume ratio, 3) the average thickness of the gas space is about 0.1 cm, and 4) the working fluid is Helium, a gas having good thermal properties for Stirling engines.

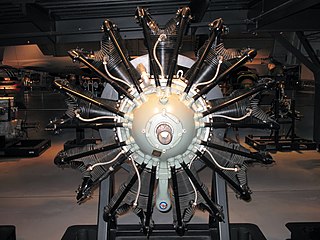

A cylinder is the central working part of a reciprocating engine or pump, the space in which a piston travels. Multiple cylinders are commonly arranged side by side in a bank, or engine block, which is typically cast from aluminum or cast iron before receiving precision machine work. Cylinders may be sleeved or sleeveless. A sleeveless engine may also be referred to as a "parent-bore engine".

The surface area of a solid object is a measure of the total area that the surface of the object occupies. The mathematical definition of surface area in the presence of curved surfaces is considerably more involved than the definition of arc length of one-dimensional curves, or of the surface area for polyhedra, for which the surface area is the sum of the areas of its faces. Smooth surfaces, such as a sphere, are assigned surface area using their representation as parametric surfaces. This definition of surface area is based on methods of infinitesimal calculus and involves partial derivatives and double integration.

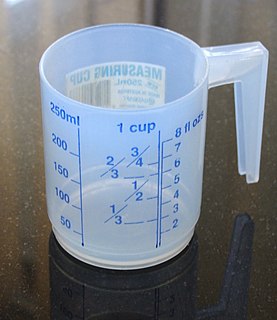

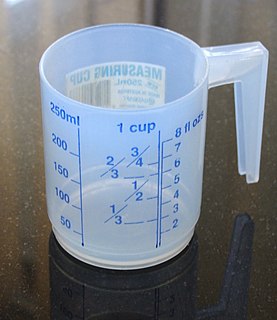

Volume is the quantity of three-dimensional space enclosed by a closed surface, for example, the space that a substance or shape occupies or contains. Volume is often quantified numerically using the SI derived unit, the cubic metre. The volume of a container is generally understood to be the capacity of the container; i. e., the amount of fluid that the container could hold, rather than the amount of space the container itself displaces. Three dimensional mathematical shapes are also assigned volumes. Volumes of some simple shapes, such as regular, straight-edged, and circular shapes can be easily calculated using arithmetic formulas. Volumes of complicated shapes can be calculated with integral calculus if a formula exists for the shape's boundary. One-dimensional figures and two-dimensional shapes are assigned zero volume in the three-dimensional space.

The engine's displacer also has very low losses. These low-loss operating characteristics simplify the engine analysis, compared to more conventional Stirling engines. [5] :113

The design has many advantages over conventional Stirling engines. The simplicity of the heater greatly reduces the cost by allowing the TMG to avoid the need for a brazed tubular or finned heater, which can account for 40% of the cost of a conventional Stirling engine. [6] The heat exchangers for the heater and cooler are mechanically trivial. The regenerator is a simple annulus, referred to as a "flat plate". Along with the cylinder wall and the displacer, there are a total of four regenerating surfaces. The TMG is a free piston engine. There are no rolling bearings or sliding seals, thus there is very little friction or wear. The working space is hermetically sealed, allowing it to contain pressurized helium gas for many thousands of hours.

Brazing is a metal-joining process in which two or more metal items are joined together by melting and flowing a filler metal into the joint, the filler metal having a lower melting point than the adjoining metal.

A bearing is a machine element that constrains relative movement to the desired motion and reduces friction between moving parts. The design of the bearing may, for example, provide for free linear movement of the moving part or for free rotation around a fixed axis; or, it may prevent a motion by controlling the vectors of normal forces that bear on the moving parts. Most bearings facilitate the desired motion by minimizing friction. Bearings are classified broadly according to the type of operation, the motions allowed, or to the directions of the loads (forces) applied to the parts.

A cylinder seal is a small round cylinder, typically about one inch in length, engraved with written characters or figurative scenes or both, used in ancient times to roll an impression onto a two-dimensional surface, generally wet clay. Cylinder seals were invented around 3500 BC in the Near East, at the contemporary sites of Uruk in southern Mesopotamia and slightly later at Susa in south-western Iran during the Proto-Elamite period, and they follow the development of stamp seals in the Halaf culture or slightly earlier. They are linked to the invention of the latter’s cuneiform writing on clay tablets. They were used as an administrative tool, a form of signature, as well as jewelry and as magical amulets; later versions would employ notations with Mesopotamian cuneiform. In later periods, they were used to notarize or attest to multiple impressions of clay documents. Graves and other sites housing precious items such as gold, silver, beads, and gemstones often included one or two cylinder seals, as honorific grave goods.

The displacer is a stainless steel can, 27 cm in diameter. It is suspended by a low-loss planer metal spring centered in a 27.4 cm diameter cylinder. The 2 mm radial clearance is divided into two concentric annular gaps by a thin, open-ended cylinder, which is fixed to the engine's cylinder. This annulus acts as the regenerator, which is much less costly than a wire-mesh type.

In metallurgy, stainless steel, also known as inox steel or inox from French inoxydable (inoxidizable), is a steel alloy, with a minimum of 10.5% chromium content by mass and a maximum of 1.2% carbon by mass.

A spring is an elastic object that stores mechanical energy. Springs are typically made of spring steel. There are many spring designs. In everyday use, the term often refers to coil springs.

In mathematics, an annulus is a ring-shaped object, a region bounded by two concentric circles. The adjectival form is annular.

The engine is a "free-cylinder" design, in which the entire engine is mounted on springs and allowed to vibrate slightly. This allows the displacer to be driven by positive feedback from the motion of the power piston and the magnets in the linear-alternator magnets, which have a combined weight of 10 kg.

A linear alternator is essentially a linear motor used as an electrical generator.

| Engine Parameter | HoMach TMG 120 Spec |

|---|

| Indicated power | 170 W |

| Shaft power | 150 W |

| Heat input | 1500 W |

| Thermal to mechanical efficiency | 10% |

| Engine frequency | 110 Hz |

| charge Pressure | 0.2 MPa |

| Displacer diameter | 26.0 cm |

| displacer stroke | 0.2 cm |

| Displacer swept volume | 110 cm³ |

| Power piston diaphragm outer diameter | 35.2 cm |

| Power piston diaphragm stroke | 0.152 cm |

| Power piston diaphragm swept volume | 110 cm³ |

| Phase angle | ~90 degrees |

| Moving mass (Power piston and alternator magnets) | 10 kg |

| Total engine mass | ~80 kg |

| Operating life | over 90000 hours |

| Helium replenishment (7 liters, at unknown pressure) | every 22500 hours on average |

[5] :109

The unique power piston was invented by Cooke-Yarborough, and is called an "articulated diaphragm". It consists of a stainless steel annulus, with an outer diameter of 35 cm and an inner diameter of 26 cm. This annulus is clamped to the engine on the outer edge by two flexible rubber o-rings, and on the inner edge it is similarly clamped, in this case to a rigid center hub that makes up the piston's center. The o-rings flex but do not slide, thus no lubricant is needed and there is negligible wear in the entire machine.

The compression space is located between the power-piston hub and the displacer, and this space is cooled by direct conduction through the power piston. A developmental model of the TMG contained a double articulated diaphragm containing cooling water, which was pumped by a thermosyphon. The depth of the compression space varies from 0.2 to 2.7 mm, as governed by the 2 mm displacer stroke and the 1.5 mm power piston stroke moving 90 degrees out of phase.

The TMG engine successfully overcomes many of the economic and mechanical difficulties common in conventional Stirling engines. However, there are some limitations of this design. The simple, low-cost annular regenerator is inefficient compared to other types, (and this contributes to this engine's somewhat low thermal efficiency of only 10%). The mechanical limitations of the articulated diaphragm only allow a maximum stroke of an estimated 3 mm. These properties limit the maximum obtainable power to about 500 - 1000 Watts from an engine of this design. [5] :195 Nevertheless, it is rare for a low-cost Stirling engine to obtain this high level of reliability and operating life, which can only be attributed to the ingenuity of the design.