Related Research Articles

Industrial ecology (IE) is the study of material and energy flows through industrial systems. The global industrial economy can be modelled as a network of industrial processes that extract resources from the Earth and transform those resources into products and services which can be bought and sold to meet the needs of humanity. Industrial ecology seeks to quantify the material flows and document the industrial processes that make modern society function. Industrial ecologists are often concerned with the impacts that industrial activities have on the environment, with use of the planet's supply of natural resources, and with problems of waste disposal. Industrial ecology is a young but growing multidisciplinary field of research which combines aspects of engineering, economics, sociology, toxicology and the natural sciences.

Extended producer responsibility (EPR) is a strategy to add all of the estimated environmental costs associated with a product throughout the product life cycle to the market price of that product, contemporarily mainly applied in the field of waste management. Such societal costs are typically externalities to market mechanisms, with a common example being the impact of cars.

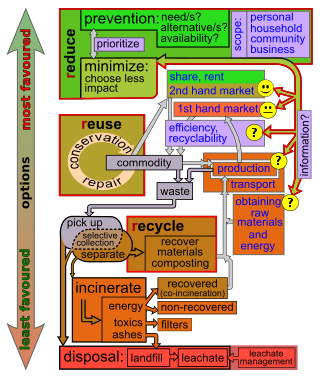

Zero waste is a set of principles focused on waste prevention that encourages redesigning resource life cycles so that all products are repurposed and/or reused. The goal of the movement is to avoid sending trash to landfills, incinerators, oceans, or any other part of the environment. Currently 9% of global plastic is recycled. In a zero waste system, all materials are reused until the optimum level of consumption is reached.

In environmental law, the polluter pays principle is enacted to make the party responsible for producing pollution responsible for paying for the damage done to the natural environment. This principle has also been used to put the costs of pollution prevention on the polluter. It is regarded as a regional custom because of the strong support it has received in most Organisation for Economic Co-operation and Development (OECD) and European Union countries. It is a fundamental principle in US environmental law.

Material efficiency is a description or metric (Mp) (the ratio of material used to the supplied material) which refers to decreasing the amount of a particular material needed to produce a specific product. Making a usable item out of thinner stock than a prior version increases the material efficiency of the manufacturing process. Material efficiency goes hand in hand with Green building and Energy conservation, as well as other ways of incorporating Renewable resources in the building process from start to finish.

Waste minimisation is a set of processes and practices intended to reduce the amount of waste produced. By reducing or eliminating the generation of harmful and persistent wastes, waste minimisation supports efforts to promote a more sustainable society. Waste minimisation involves redesigning products and processes and/or changing societal patterns of consumption and production.

Cleaner production is a preventive, company-specific environmental protection initiative. It is intended to minimize waste and emissions and maximize product output. By analysing the flow of materials and energy in a company, one tries to identify options to minimize waste and emissions out of industrial processes through source reduction strategies. Improvements of organisation and technology help to reduce or suggest better choices in use of materials and energy, and to avoid waste, waste water generation, and gaseous emissions, and also waste heat and noise.

Precycling is the practice of reducing waste by attempting to avoid buying items which will generate waste into home or business. The U.S. Environmental Protection Agency (EPA) also cites that precycling is the preferred method of integrated solid waste management because it cuts waste at its source and therefore trash is eliminated before it is created. According to the EPA, precycling is also characterized as a decision-making process on the behalf of the consumer because it involves making informed judgments regarding a product's waste implications. The implications that are taken into consideration by the consumer include: whether a product is reusable, durable, or repairable; made from renewable or non-renewable resources; over-packaged; and whether or not the container is reusable.

Product-service systems (PSS) are business models that provide for cohesive delivery of products and services. PSS models are emerging as a means to enable collaborative consumption of both products and services, with the aim of pro-environmental outcomes.

Recycling in Japan, an aspect of waste management in Japan, is based on the Japanese Container and Packaging Recycling Law. Plastic, paper, PET bottles, aluminium and glass are collected and recycled. Japan’s country profile in Waste Atlas shows that in 2012 Recycling Rate was 20.8%.

Chemical leasing is a business model that intends to shift the focus from increasing sales volume of chemicals towards a value-added approach. It intends to address unnecessary over-consumption of chemicals by charging consumers based on functions performed by the chemicals rather than by volume. This treatment of chemical supply as selling a service than selling a product leads to efficient use of chemicals, and to improved health and safety, environmental, and economic benefits.

Electronic waste is a significant part of today's global, post-consumer waste stream. Efforts are being made to recycle and reduce this waste.

The OECD Environmental Performance Reviews programme provides independent assessments of countries’ progress in achieving domestic and international environmental policy commitments. The programme has completed over 60 reviews that aim to help improve individual and collective performance in environmental management by: promoting peer learning; enhancing countries’ accountability to each other and to the public; and helping governments to assess progress in achieving their environmental goals.

A circular economy is a model of production and consumption, which involves sharing, leasing, reusing, repairing, refurbishing and recycling existing materials and products for as long as possible. CE aims to tackle global challenges such as climate change, biodiversity loss, waste, and pollution by emphasizing the design-based implementation of the three base principles of the model. The three principles required for the transformation to a circular economy are: designing out waste and pollution, keeping products and materials in use, and regenerating natural systems." CE is defined in contradistinction to the traditional linear economy. The idea and concepts of circular economy (CE) have been studied extensively in academia, business, and government over the past ten years. CE has been gaining popularity because it helps to minimize emissions and consumption of raw materials, open up new market prospects and principally, increase the sustainability of consumption and improve resource efficiency.

Sustainable products are those products that provide environmental, social and economic benefits while protecting public health and environment over their whole life cycle, from the extraction of raw materials until the final disposal.

Resource recovery is using wastes as an input material to create valuable products as new outputs. The aim is to reduce the amount of waste generated, thereby reducing the need for landfill space, and optimising the values created from waste. Resource recovery delays the need to use raw materials in the manufacturing process. Materials found in municipal solid waste, construction and demolition waste, commercial waste and industrial wastes can be used to recover resources for the manufacturing of new materials and products. Plastic, paper, aluminium, glass and metal are examples of where value can be found in waste.

Appliance recycling is the process of dismantling scrapped home appliances to recover their parts or materials for reuse. Recycling appliances for their original or other purposes, involves disassembly, removal of hazardous components and destruction of the equipment to recover materials, generally by shredding, sorting and grading. The rate at which appliances are discarded has increased due in part to obsolescence due to technological advancement, and in part to not being designed to be repairable. The main types of appliances that are recycled are televisions, refrigerators, air conditioners, washing machines, and computers. When appliances are recycled, they can be looked upon as a valuable resources; if disposed of improperly, they can be environmentally harmful and poison ecosystems.

The UNECE Environmental Performance Review (EPR) is an assessment process to evaluate the progress made by individual countries in improving their environmental policies. The EPRs are carried out under the auspices of the Committee on Environmental Policy of the United Nations Economic Commission for Europe (UNECE).

Environmental systems analysis (ESA) is a systematic and systems based approach for describing human actions impacting on the natural environment to support decisions and actions aimed at perceived current or future environmental problems. Impacts of different types of objects are studied that ranges from projects, programs and policies, to organizations, and products. Environmental systems analysis encompasses a family of environmental assessment tools and methods, including life cycle assessment (LCA), material flow analysis (MFA) and substance flow analysis (SFA), and environmental impact assessment (EIA), among others.

A circular economy is an alternative way countries manage their resources, where instead of using products in the traditional linear make, use, dispose method, resources are used for their maximum utility throughout its life cycle and regenerated in a cyclical pattern minimizing waste. They strive to create economic development through environmental and resource protection. The ideas of a circular economy were officially adopted by China in 2002, when the 16th National Congress of the Chinese Communist Party legislated it as a national endeavour, though various sustainability initiatives were implemented in the previous decades starting in 1973. China adopted the circular economy due to the environmental damage and resource depletion that was occurring from going through its industrialization process. China is currently a world leader in the production of resources, where it produces 46% of the worlds aluminum, 50% of steel and 60% of cement, while it has consumed more raw materials than all the countries a part of the Organisation for Economic Co-operation and Development (OECD) combined. In 2014, China created 3.2 billion tonnes of industrial solid waste, where 2 billion tonnes were recovered using recycling, incineration, reusing and composting. By 2025, China is anticipated to produce up to one quarter of the worlds municipal solid waste.

References

- ↑ Van Rossem, C, Tojo, N, & Lindhqvist, T, 2006, "Extended Producer Responsibility: An examination of its impact on innovation and greening products" http://www.greenpeace.org/international/PageFiles/24472/epr.pdf

- ↑ Thomas Lindhqvist, Staff Profiles, International Institute for Industrial Environmental Economics http://www.iiiee.lu.se/people/thomas-lindhqvist

- ↑ Thomas Lindhqvist, Coursera Profile https://www.coursera.org/instructor/thomaslindhqvist