Related Research Articles

Pressure measurement is the measurement of an applied force by a fluid on a surface. Pressure is typically measured in units of force per unit of surface area. Many techniques have been developed for the measurement of pressure and vacuum. Instruments used to measure and display pressure mechanically are called pressure gauges,vacuum gauges or compound gauges. The widely used Bourdon gauge is a mechanical device, which both measures and indicates and is probably the best known type of gauge.

A valve is a device or natural object that regulates, directs or controls the flow of a fluid by opening, closing, or partially obstructing various passageways. Valves are technically fittings, but are usually discussed as a separate category. In an open valve, fluid flows in a direction from higher pressure to lower pressure. The word is derived from the Latin valva, the moving part of a door, in turn from volvere, to turn, roll.

Flow measurement is the quantification of bulk fluid movement. Flow can be measured in a variety of ways. The common types of flowmeters with industrial applications are listed below:

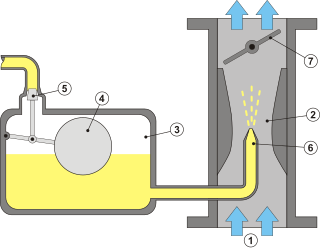

A float chamber is a device for automatically regulating the supply of a liquid to a system. It is most typically found in the carburettor of an internal combustion engine, where it automatically meters the fuel supply to the engine. However, this arrangement is found in many automatic liquid systems, for example the cistern of most toilets could be said to be a type of float chamber.

A check valve, non-return valve, reflux valve, retention valve, foot valve, or one-way valve is a valve that normally allows fluid to flow through it in only one direction.

A rotameter is a device that measures the volumetric flow rate of fluid in a closed tube.

An anaesthetic machine or anesthesia machine is a medical device used to generate and mix a fresh gas flow of medical gases and inhalational anaesthetic agents for the purpose of inducing and maintaining anaesthesia.

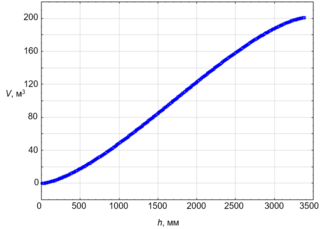

A gas meter is a specialized flow meter, used to measure the volume of fuel gases such as natural gas and liquefied petroleum gas. Gas meters are used at residential, commercial, and industrial buildings that consume fuel gas supplied by a gas utility. Gases are more difficult to measure than liquids, because measured volumes are highly affected by temperature and pressure. Gas meters measure a defined volume, regardless of the pressurized quantity or quality of the gas flowing through the meter. Temperature, pressure, and heating value compensation must be made to measure actual amount and value of gas moving through a meter.

Dräger is a German company based in Lübeck which makes breathing and protection equipment, gas detection and analysis systems, and noninvasive patient monitoring technologies. Customers include hospitals, fire departments and diving companies.

Choked flow is a compressible flow effect. The parameter that becomes "choked" or "limited" is the fluid velocity.

A needle valve is a type of valve with a small port and a threaded, needle-shaped plunger. It allows precise regulation of flow, although it is generally only capable of relatively low flow rates.

High-frequency ventilation is a type of mechanical ventilation which utilizes a respiratory rate greater than four times the normal value. and very small tidal volumes. High frequency ventilation is thought to reduce ventilator-associated lung injury (VALI), especially in the context of ARDS and acute lung injury. This is commonly referred to as lung protective ventilation. There are different types of high-frequency ventilation. Each type has its own unique advantages and disadvantages. The types of HFV are characterized by the delivery system and the type of exhalation phase.

The term separator in oilfield terminology designates a pressure vessel used for separating well fluids produced from oil and gas wells into gaseous and liquid components. A separator for petroleum production is a large vessel designed to separate production fluids into their constituent components of oil, gas and water. A separating vessel may be referred to in the following ways: Oil and gas separator, Separator, Stage separator, Trap, Knockout vessel, Flash chamber, Expansion separator or expansion vessel, Scrubber, Filter. These separating vessels are normally used on a producing lease or platform near the wellhead, manifold, or tank battery to separate fluids produced from oil and gas wells into oil and gas or liquid and gas. An oil and gas separator generally includes the following essential components and features:

A positive displacement meter is a type of flow meter that requires fluid to mechanically displace components in the meter in order for flow measurement. Positive displacement (PD) flow meters measure the volumetric flow rate of a moving fluid or gas by dividing the media into fixed, metered volumes. A basic analogy would be holding a bucket below a tap, filling it to a set level, then quickly replacing it with another bucket and timing the rate at which the buckets are filled. With appropriate pressure and temperature compensation, the mass flow rate can be accurately determined.

Custody Transfer in the oil and gas industry refers to the transactions involving transporting physical substance from one operator to another. This includes the transferring of raw and refined petroleum between tanks and railway tank cars; onto ships, and other transactions. Custody transfer in fluid measurement is defined as a metering point (location) where the fluid is being measured for sale from one party to another. During custody transfer, accuracy is of great importance to both the company delivering the material and the eventual recipient, when transferring a material.

A pressure carburetor is a type of fuel metering system manufactured by the Bendix Corporation for piston aircraft engines, starting in the 1940s. It is recognized as an early type of throttle-body fuel injection and was developed to prevent fuel starvation during inverted flight.

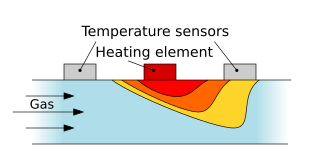

Thermal mass flow meters, also known as thermal dispersion or immersible mass flow meters, comprise a family of instruments for the measurement of the total mass flow rate of a fluid, primarily gases, flowing through closed conduits. A second type is the capillary-tube type of thermal mass flow meter. Many mass flow controllers (MFC) which combine a mass flow meter, electronics and a valve are based on this design. Furthermore, a thermal mass flow meter can be built by measuring temperature differential across a silicon-based MEMS chip.

Of the three types of carburetors used on large, high-performance aircraft engines manufactured in the United States during World War II, the Bendix-Stromberg pressure carburetor was the one most commonly found. The other two carburetor types were manufactured by Chandler Groves and Chandler Evans Control Systems (CECO). Both of these types of carburetors had a relatively large number of internal parts, and in the case of the Holley Carburetor, there were complications in its "variable venturi" design.

Station Outlets (US) or Terminal Units consist of an outlet port with color-coded faceplate attached to a medical gas supply line, and primary and secondary check valves which open and close automatically upon use and disengagement from the system. In most jurisdictions, Station Outlets are required to be equipped with safety systems that prevent cross-connection errors, such as connecting a Medical air flowmeter to an Oxygen port. Hospitals mainly use DISS connections, though a wide variety of quick-connect adapters, based on male strikers and female outlet ports, are still in use today. These latter types are easier to connect, but are more prone to leaks and failure.

A Diving rebreather is an underwater breathing apparatus that absorbs the carbon dioxide of a diver's exhaled breath to permit the rebreathing (recycling) of the substantially unused oxygen content, and unused inert content when present, of each breath. Oxygen is added to replenish the amount metabolised by the diver. This differs from open-circuit breathing apparatus, where the exhaled gas is discharged directly into the environment. The purpose is to extend the breathing endurance of a limited gas supply, and, for covert military use by frogmen or observation of underwater life, to eliminate the bubbles produced by an open circuit system. A diving rebreather is generally understood to be a portable unit carried by the user, and is therefore a type of self-contained underwater breathing apparatus (scuba). A semi-closed rebreather carried by the diver may also be known as a gas extender. The same technology on a submersible or surface installation is more likely to be referred to as a life-support system.

References

- Branson, Richard D., et al. 'Respiratory Care Equipment, 2nd Edition'. Cont. Banner et al. pp. 58–62. (Philadelphia: Lippincott Williams & Wilkins, 1999).

- Cairo, J.M., et Pilbeam, Susan. 'Mosby's Respiratory Care Equipment'. Ed. Kelli Chronister et al. pp. 61–62. (St. Louis, Missouri: Mosby Elsevier, 2010).

- Wilkins, Robert L. et al. 'Egan's Fundamentals of Respiratory Care, Ninth Edition'. Ed. Lucy Kester et al. pp. 862–865, 898-899. (St. Louis, Missouri: Mosby Elsevier, 2009).