A conveyor belt is the carrying medium of a belt conveyor system. A belt conveyor system is one of many types of conveyor systems. A belt conveyor system consists of two or more pulleys, with a closed loop of carrying medium—the conveyor belt—that rotates about them. One or both of the pulleys are powered, moving the belt and the material on the belt forward. The powered pulley is called the drive pulley while the unpowered pulley is called the idler pulley. There are two main industrial classes of belt conveyors; Those in general material handling such as those moving boxes along inside a factory and bulk material handling such as those used to transport large volumes of resources and agricultural materials, such as grain, salt, coal, ore, sand, overburden and more.

A bucket-wheel excavator (BWE) is a large heavy equipment machine used in surface mining.

A coal preparation plant is a facility that washes coal of soil and rock, crushes it into graded sized chunks (sorting), stockpiles grades preparing it for transport to market, and more often than not, also loads coal into rail cars, barges, or ships.

A variable rate feeder is a piece of industrial control equipment used to deliver solid material at a known rate into some process.

TAKRAF Group (“TAKRAF”) is a global German industrial company. Through its brands, TAKRAF and DELKOR, the Group provides equipment, systems and services to the mining and associated industries, with a focus on energy saving, lowering environmental impact and meeting operational requirements.

Material handling equipment (MHE) is mechanical equipment used for the movement, storage, control, and protection of materials, goods and products throughout the process of manufacturing, distribution, consumption, and disposal. The different types of equipment can be classified into four major categories: transport equipment, positioning equipment, unit load formation equipment, and storage equipment.

A conveyor system is a common piece of mechanical handling equipment that moves materials from one location to another. Conveyors are especially useful in applications involving the transport of heavy or bulky materials. Conveyor systems allow quick and efficient transport for a wide variety of materials, which make them very popular in the material handling and packaging industries. They also have popular consumer applications, as they are often found in supermarkets and airports, constituting the final leg of item/ bag delivery to customers. Many kinds of conveying systems are available and are used according to the various needs of different industries. There are chain conveyors as well. Chain conveyors consist of enclosed tracks, I-Beam, towline, power & free, and hand pushed trolleys.

A chain conveyor is a type of conveyor system for moving material through production lines.

FLSmidth & Co. A/S is a Danish multinational engineering company based in Copenhagen, Denmark. With over 10,000 employees worldwide, it provides global cement and mineral industries with factories, machinery, services and know-how. FLSmidth is listed on NASDAQ OMX Nordic Copenhagen in the C20 index and has offices in more than 50 countries worldwide.

Photoanalysis refers to the study of pictures to compile various types of data, for example, to measure the size distribution of virtually anything that can be captured by photo. Photoanalysis technology has changed the way mines and mills quantify fragmented material.

Superior Industries, Inc. is an American manufacturing company headquartered in Morris, Minnesota. The company engineers, manufactures, sells and supports dry bulk processing and handling equipment and components. In 2008, Superior acquired Westmor Industries, a manufacturer and distributor of energy storage, transportation and dispensing equipment also headquartered in Morris.

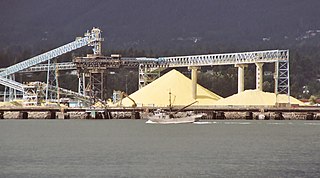

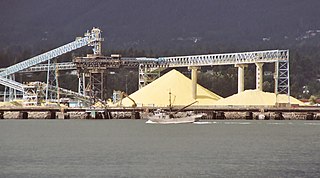

A shiploader is a large machine used for continuously loading bulk solid materials such as iron ore, coal, fertilizers, grains and/or material in bags onto ships or barges. These machines are located in ports and jetties to facilitate bulk material exportation. Generally shiploaders are engineered to suit specific project requirements. Those requirements often include: port design, material characteristics, loading capacity, vessel type, local law, and budgetary limitations. A shiploader mainly consists of a central column, an extendable arm or boom, a belt conveyor extending out of the boom structure, a slewing mechanism, and a loading chute to transfer product from a source conveyor or feeder. The boom can move front and back, up and down by separate drives so that it can fill the whole breadth of the ship hold and adapt to the ships increasing draught while it is loaded.

P&H Mining Equipment designs, builds and supports a line of drilling and material handling machinery marketed under the "P&H" trademark and applied to minerals and energy surface mining operations worldwide. The firm is an operating subsidiary of Joy Global Inc. In 2017 Joy Global Inc. was acquired by Komatsu Limited of Tokyo, Japan and is now known as Komatsu Mining Corporation and operate as a subsidiary of Komatsu.

Joy Global Inc. was a company that manufactured and serviced heavy equipment used in the extraction and haulage of coal and minerals in both underground and surface mining. The company had manufacturing facilities in Alabama, Pennsylvania, Texas, Wisconsin, Australia, Canada, China, France, South Africa and the United Kingdom. In 2017, Joy Global was acquired by Komatsu Limited and was renamed Komatsu Mining Corp.

RNA Automation, a member of Rhein-Nadel Automation, was established in Birmingham UK in 1986, and has progressed into becoming the major supplier of parts handling equipment in the UK. The company operates in the area of specialised Automation engineering, providing automatic parts handling equipment for high volume production in the cosmetics, pharmaceutical, electronics, food and metal working industries, with seven manufacturing facilities across Europe and North America and a network of sales and service outlets across the globe.

Sensor-based sorting, is an umbrella term for all applications in which particles are detected using a sensor technique and rejected by an amplified mechanical, hydraulic or pneumatic process.

AUMUND Fördertechnik GmbH, commonly known as Aumund, is a German producer of conveying technology and is headquartered in Rheinberg, district of Millingen. The company was founded in 1922 by Professor Heinrich Aumund and is today managed by his grandson, Franz-Walter Aumund. Aumund nowadays has around 390 employees, 10 branches worldwide and a wide network of local representatives.

TAKRAF India Private Limited is a wholly owned subsidiary of TAKRAF GmbH. As with its parent company, TAKRAF India provides equipment, systems and services to the mining and associated industries through the TAKRAF and DELKOR brands.

Tega Industries Ltd. is an Indian corporation, headquartered in Kolkata. A constituent of MM Group of Companies, it provides customized products and services for mining, mineral beneficiation, bulk material handling, and slurry transportation industries.

NIAflow is simulation software for mineral processing plants. Based on a flowsheet interface, it calculates the material flow through a variety of processing machinery.