A pump is a device that moves fluids, or sometimes slurries, by mechanical action, typically converted from electrical energy into Hydraulic energy. Pumps can be classified into three major groups according to the method they use to move the fluid: direct lift, displacement, and gravity pumps.

A vacuum pump is a device that removes gas molecules from a sealed volume in order to leave behind a partial vacuum. The first vacuum pump was invented in 1650 by Otto von Guericke, and was preceded by the suction pump, which dates to antiquity.

A vacuum cleaner, also known simply as a vacuum, is a device that causes suction in order to remove debris from floors, upholstery, draperies and other surfaces. It is generally electrically driven.

Appropriate technology is a movement encompassing technological choice and application that is small-scale, affordable by locals, decentralized, labor-intensive, energy-efficient, environmentally sound, and locally autonomous. It was originally articulated as intermediate technology by the economist Ernst Friedrich "Fritz" Schumacher in his work Small Is Beautiful. Both Schumacher and many modern-day proponents of appropriate technology also emphasize the technology as people-centered.

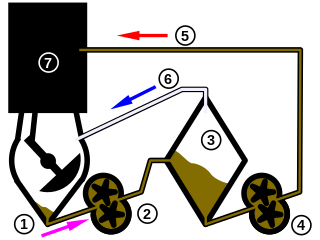

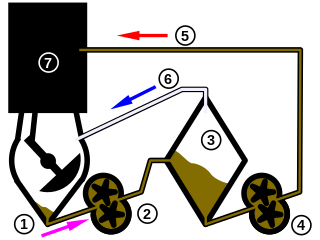

A dry-sump system is a method to manage the lubricating motor oil in four-stroke and large two-stroke piston driven internal combustion engines. The dry-sump system uses two or more oil pumps and a separate oil reservoir, as opposed to a conventional wet-sump system, which uses only the main sump below the engine and a single pump. A dry-sump engine requires a pressure relief valve to regulate negative pressure inside the engine, so internal seals are not inverted.

An irrigation sprinkler is a device used to irrigate agricultural crops, lawns, landscapes, golf courses, and other areas. They are also used for cooling and for the control of airborne dust. Sprinkler irrigation is the method of applying water in a controlled manner in way similar to rainfall. The water is distributed through a network that may consist of pumps, valves, pipes, and sprinklers.

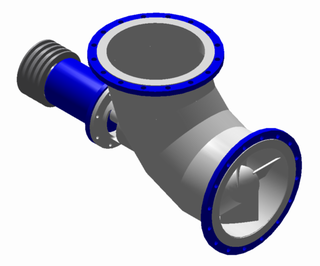

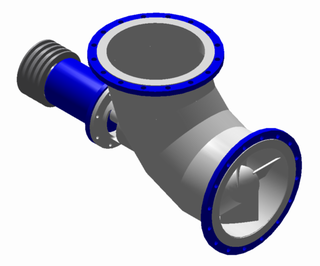

An axial-flow pump, or AFP, is a common type of pump that essentially consists of a propeller in a pipe. The propeller can be driven directly by a sealed motor in the pipe or by electric motor or petrol/diesel engines mounted to the pipe from the outside or by a right-angle drive shaft that pierces the pipe.

Worldwide more human beings gain their livelihood from agriculture than any other endeavor; the majority are self-employed subsistence farmers living in the tropics. While growing food for local consumption is the core of tropical agriculture, cash crops are also included in the definition.

Hand pumps are manually operated pumps; they use human power and mechanical advantage to move fluids or air from one place to another. They are widely used in every country in the world for a variety of industrial, marine, irrigation and leisure activities. There are many different types of hand pump available, mainly operating on a piston, diaphragm or rotary vane principle with a check valve on the entry and exit ports to the chamber operating in opposing directions. Most hand pumps are either piston pumps or plunger pumps, and are positive displacement.

Solar-powered pumps run on electricity generated by photovoltaic panels or the radiated thermal energy available from collected sunlight as opposed to grid electricity or diesel run water pumps. The operation of solar powered pumps is more economical mainly due to the lower operation and maintenance costs and has less environmental impact than pumps powered by an internal combustion engine (ICE). Solar pumps are useful where grid electricity is unavailable and alternative sources do not provide sufficient energy.

iDE, formerly International Development Enterprises, is an international nonprofit organization that promotes a business approach to increasing income and creating livelihood opportunities for poor rural households. iDE was founded in 1982 by Paul Polak, a Denver, Colorado psychiatrist who promoted the concept of helping poor people become entrepreneurs instead of simply giving them handouts. Originally, iDE was devoted to the manufacture, marketing, and distribution of affordable, scalable micro-irrigation and low-cost water recovery systems throughout the developing world. iDE facilitates local manufacture and distribution of these products through local supply chains that sell to farmers at an affordable price which they can repay in one growing season. This strategy allows farmers to grow higher value and surplus crops, and in turn links them to high-value crop markets where they can realize profits from their higher yields. Recently, their success is in the promotion of sanitation products to decrease the practice of open defecation leading to diarrheal disease.

In 1993, the country's groundwater, the source of drinking water for 97% of the rural population and a significant share of the urban population, was contaminated with arsenic. However, in 2004, 98% of the population already has access to an improved water source, a very high level for a low-income country. This has been achieved through the construction of hand pumps with the support of external donors.

Paul Polak was the co-founder and CEO of Windhorse International, a for-profit social venture with the mission of inspiring and leading a revolution in how companies design, price, market and distribute products to benefit the 2.6 billion customers who live on less than $2 a day.

Flexible suction hose, not to be confused with hard suction hose in U.S., is a specific type of fire hose used in drafting operations, when a fire engine uses a vacuum to draw water from a portable water tank, pool, or other static water source. It is built to withstand vacuum, rather than pressure, abrasion, and heat. Conversely, hard suction is capable of withstanding up to 200 PSIG, as well as vacuum. In the United States, it is standard equipment according to the National Fire Protection Association standards for fire engines. It is used in both structural and wildland firefighting throughout the world, and is made in various diameters and connection types.

The environmental impacts of irrigation relate to the changes in quantity and quality of soil and water as a result of irrigation and the effects on natural and social conditions in river basins and downstream of an irrigation scheme. The impacts stem from the altered hydrological conditions caused by the installation and operation of the irrigation scheme.

Proximity Designs is a not-for-profit social enterprise working to help reduce poverty for rural families in Myanmar (Burma). They design and market products and services that low-income farmers purchase and use to help increase their incomes. The organisation sells foot-powered irrigation pumps, water storage tanks, drip irrigation systems, solar lighting and farm advisory services. Proximity distributes its products and services through a network of private sector agro-dealers and independent village-level agents that reaches approximately 80 percent of Myanmar's rural population. The products are designed to help farmers grow higher value crops and significantly increase their annual incomes. Since starting in 2004, more than 110,000 Proximity products have been purchased by farm households in Myanmar. Following the disaster of Cyclone Nargis in 2008, the organisation became active in designing and implementing humanitarian relief and recovery efforts for entire communities. It is a 501(c)3 non-profit organisation registered in California with operations in Myanmar.

EOS International is a 501c3 not-profit organization founded in 2008 and dedicated to promoting appropriate technology in the developing world. EOS works primarily in Nicaragua providing rural families with access to low-cost technologies geared towards generating income and improving health. The three core technologies EOS implements include: drip irrigation systems, fuel-efficient barrel ovens, and biodigestors.

Boiler design is the process of designing boilers used for various purposes. The main function of a boiler is to heat water to generate steam. Steam produced in a boiler can be used for a variety of purposes including space heating, sterilisation, drying, humidification and power generation. The temperature or condition of steam required for these applications is different, so boiler designs vary accordingly.

The Appropriate Technology Collaborative is a U.S. Non-profit dedicated to designing everyday technologies for the global poor.

KickStart International is a nonprofit social enterprise based in San Francisco that designs and mass-markets manually-powered irrigation pumps to poor rural farmers in sub-Saharan Africa. KickStart uses donor funds to design the pumps, establish the supply chains, demonstrate and promote the pumps, and educate farmers about the benefits and methods of irrigation.