Stephenson's Rocket was an early steam locomotive of 0-2-2 wheel arrangement. It was built for, and won, the Rainhill Trials held by the Liverpool and Manchester Railway in 1829 to choose the best design to power the railway.

A steam locomotive is a type of railway locomotive that produces its pulling power through a steam engine. These locomotives are fueled by burning combustible material – usually coal, wood, or oil – to produce steam in a boiler. The steam moves reciprocating pistons which are mechanically connected to the locomotive's main wheels (drivers). Both fuel and water supplies are carried with the locomotive, either on the locomotive itself or in wagons (tenders) pulled behind.

This is a glossary of the components found on typical steam locomotives.

A fire-tube boiler is a type of boiler in which hot gases pass from a fire through one or (many) more tubes running through a sealed container of water. The heat of the gases is transferred through the walls of the tubes by thermal conduction, heating the water and ultimately creating steam.

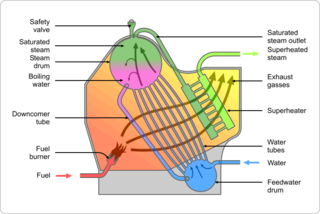

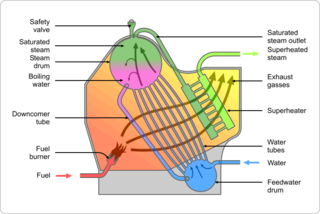

A high pressure watertube boiler is a type of boiler in which water circulates in tubes heated externally by the fire. Fuel is burned inside the furnace, creating hot gas which heats water in the steam-generating tubes. In smaller boilers, additional generating tubes are separate in the furnace, while larger utility boilers rely on the water-filled tubes that make up the walls of the furnace to generate steam.

In a steam engine, the firebox is the area where the fuel is burned, producing heat to boil the water in the boiler. Most are somewhat box-shaped, hence the name. The hot gases generated in the firebox are pulled through a rack of tubes running through the boiler.

A fireman, stoker or watertender, is a person whose occupation it is to tend the fire for the running of a boiler, heating a building, or powering a steam engine. Much of the job is hard physical labor, such as shoveling fuel, typically coal, into the boiler's firebox. On steam locomotives the title fireman is usually used, while on steamships and stationary steam engines, such as those driving saw mills, the title is usually stoker. The German word Heizer is equivalent and in Dutch the word stoker is mostly used too. The United States Navy referred to them as watertenders.

A smokebox is one of the major basic parts of a steam locomotive exhaust system. Smoke and hot gases pass from the firebox through tubes where they pass heat to the surrounding water in the boiler. The smoke then enters the smokebox, and is exhausted to the atmosphere through the chimney. Early locomotives had no smokebox and relied on a long chimney to provide natural draught for the fire but smokeboxes were soon included in the design for two main reasons. Firstly and most importantly, the blast of exhaust steam from the cylinders, when directed upwards through an airtight smokebox with an appropriate design of exhaust nozzle, effectively draws hot gases through the boiler tubes and flues and, consequently, fresh combustion air into the firebox. Secondly, the smokebox provides a convenient collection point for ash and cinders ("char") drawn through the boiler tubes, which can be easily cleaned out at the end of a working day. Without a smokebox, all char must pass up the chimney or will collect in the tubes and flues themselves, gradually blocking them.

The Deutsche Reichsbahn-Gesellschaft's BR 01 steam locomotives were the first standardised (Einheitsdampflokomotive) steam express passenger locomotives built by the unified German railway system. They were of 4-6-2 "Pacific" wheel arrangement in the Whyte notation, or 2′C1′ h2 in the UIC classification. The idea of standardisation was that it would reduce maintenance costs; i.e. if a BR 01 whose engine shop was in, say, Berlin broke down in Dresden, instead of having to ship the necessary part from Berlin and take the locomotive out of service, a part from the Dresden shop could be used as all of the engines, parts, and workings were exactly the same and produced nationwide. Thus it was a "standard" product for engine shops.

A steam generator is a type of boiler used to produce steam for climate control and potable water heating in railroad passenger cars. The output of a railroad steam generator is low pressure, saturated steam that is passed through a system of pipes and conduits throughout the length of the train.

The DRB Class 50 is a German class of 2-10-0 locomotive, built from 1939 as a standard locomotive (Einheitsdampflokomotive) for hauling goods trains. It had one leading axle and five coupled axles and was one of the most successful designs produced for the Deutsche Reichsbahn.

A Bahnbetriebswerk is a German railway depot where the maintenance of locomotives and other rolling stock is carried out. It is roughly equivalent to a locomotive shed, running shed or motive power depot. These were of great importance during the steam locomotive era to ensure the smooth running of locomotive-hauled services. Bahnbetriebswerke had a large number of facilities in order to be able to carry out their various maintenance tasks. As a result, they needed a lot of staff and were often the largest employers in the area.

A shell or flued boiler is an early and relatively simple form of boiler used to make steam, usually for the purpose of driving a steam engine. The design marked a transitional stage in boiler development, between the early haystack boilers and the later multi-tube fire-tube boilers. A flued boiler is characterized by a large cylindrical boiler shell forming a tank of water, traversed by one or more large flues containing the furnace. These boilers appeared around the start of the 19th century and some forms remain in service today. Although mostly used for static steam plants, some were used in early steam vehicles, railway locomotives and ships.

Yarrow boilers are an important class of high-pressure water-tube boilers. They were developed by Yarrow & Co. (London), Shipbuilders and Engineers and were widely used on ships, particularly warships.

Boilers for generating steam or hot water have been designed in countless shapes, sizes and configurations. An extensive terminology has evolved to describe their common features. This glossary provides definitions for these terms.

The Sentinel boiler was a design of vertical boiler, fitted to the numerous steam waggons built by the Sentinel Waggon Works.

Three-drum boilers are a class of water-tube boiler used to generate steam, typically to power ships. They are compact and of high evaporative power, factors that encourage this use. Other boiler designs may be more efficient, although bulkier, and so the three-drum pattern was rare as a land-based stationary boiler.

The chimney is the part of a steam locomotive through which smoke leaves the boiler. Steam locomotive exhaust systems typically vent cylinder exhaust through the chimney to enhance draught through the boiler. Chimneys are designed to carry exhaust steam and smoke clear of the driver's line of sight while remaining short enough to clear overhead structures. Some chimneys included features to avoid dispersing sparks.

A high-pressure steam locomotive is a steam locomotive with a boiler that operates at pressures well above what would be considered normal. In the later years of steam, boiler pressures were typically 200 to 250 psi. High-pressure locomotives can be considered to start at 350 psi (2.41 MPa), when special construction techniques become necessary, but some had boilers that operated at over 1,500 psi (10.34 MPa).