In metalworking and jewellery making, casting is a process in which a liquid metal is somehow delivered into a mold that contains a negative impression of the intended shape. The metal is poured into the mold through a hollow channel called a sprue. The metal and mold are then cooled, and the metal part is extracted. Casting is most often used for making complex shapes that would be difficult or uneconomical to make by other methods.

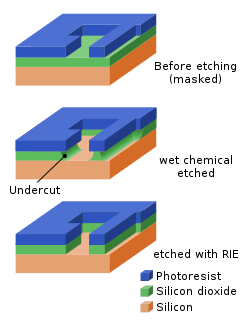

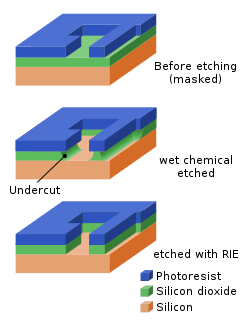

Isotropic etching is a method commonly used in semiconductors to remove material from a substrate via a chemical process using an etchant substance. The etchant may be in liquid-, gas- or plasma-phase, although liquid etchants such as buffered hydrofluoric acid (BHF) for silicon dioxide etching are more often used. Unlike anisotropic etching, isotropic etching does not etch in a single direction, but rather etches in multiple directions within the substrate. Any horizontal component of the etch direction may therefore result in undercutting of patterned areas, and significant changes to device characteristics. Isotropic etching may occur unavoidably, or it may be desirable for process reasons.

Hobbing is a machining process for gear cutting, cutting splines, and cutting sprockets on a hobbing machine, which is a special type of milling machine. The teeth or splines of the gear are progressively cut into the material by a series of cuts made by a cutting tool called a hob. Compared to other gear forming processes it is relatively inexpensive but still quite accurate, thus it is used for a broad range of parts and quantities.

Broaching is a machining process that uses a toothed tool, called a broach, to remove material. There are two main types of broaching: linear and rotary. In linear broaching, which is the more common process, the broach is run linearly against a surface of the workpiece to effect the cut. Linear broaches are used in a broaching machine, which is also sometimes shortened to broach. In rotary broaching, the broach is rotated and pressed into the workpiece to cut an axisymmetric shape. A rotary broach is used in a lathe or screw machine. In both processes the cut is performed in one pass of the broach, which makes it very efficient.

A counterbore is a cylindrical flat-bottomed hole that enlarges another coaxial hole, or the tool used to create that feature. A counterbore hole is typically used when a fastener, such as a socket head cap screw, is required to sit flush with or below the level of a workpiece's surface.

Lost-foam casting (LFC) is a type of evaporative-pattern casting process that is similar to investment casting except foam is used for the pattern instead of wax. This process takes advantage of the low boiling point of polymer foams to simplify the investment casting process by removing the need to melt the wax out of the mold.

Evaporative-pattern casting is a type of casting process that uses a pattern made from a material that will evaporate when the molten metal is poured into the molding cavity. The most common evaporative-pattern material used is polystyrene foam.

Gray iron, or grey cast iron, is a type of cast iron that has a graphitic microstructure. It is named after the gray color of the fracture it forms, which is due to the presence of graphite. It is the most common cast iron and the most widely used cast material based on weight.

Surface finish, also known as surface texture or surface topography, is the nature of a surface as defined by the three characteristics of lay, surface roughness, and waviness. It comprises the small, local deviations of a surface from the perfectly flat ideal.

Etching is used in microfabrication to chemically remove layers from the surface of a wafer during manufacturing. Etching is a critically important process module, and every wafer undergoes many etching steps before it is complete.

A chill is an object used to promote solidification in a specific portion of a metal casting mold. Normally the metal in the mould cools at a certain rate relative to thickness of the casting. When the geometry of the molding cavity prevents directional solidification from occurring naturally, a chill can be strategically placed to help promote it. There are two types of chills: internal and external chills.

Permanent mold casting is a metal casting process that employs reusable molds, usually made from metal. The most common process uses gravity to fill the mold, however gas pressure or a vacuum are also used. A variation on the typical gravity casting process, called slush casting, produces hollow castings. Common casting metals are aluminium, magnesium, and copper alloys. Other materials include tin, zinc, and lead alloys and iron and steel are also cast in graphite molds.

Full-mold casting is an evaporative-pattern casting process which is a combination of sand casting and lost-foam casting. It uses an expanded polystyrene foam pattern which is then surrounded by sand, much like sand casting. The metal is then poured directly into the mold, which vaporizes the foam upon contact.

Photochemical machining (PCM), also known as photochemical milling or photo etching, is a chemical milling process used to fabricate sheet metal components using a photoresist and etchants to corrosively machine away selected areas. This process emerged in the 1960s as an offshoot of the printed circuit board industry. Photo etching can produce highly complex parts with very fine detail accurately and economically.

Stock removal is the process of removing material (stock) from a workpiece. Stock removal processes include:

Free machining steel is steel that forms small chips when machined. This increases the machinability of the material by breaking the chips into small pieces, thus avoiding entanglement in the machinery. This enables automatic equipment to run without human interaction. Free machining steel with lead also allow for higher machining rates. Free machining steel costs 15 to 20% more than standard steel, but this higher cost is offset by increased machining speeds, larger cuts, and longer tool life.

In manufacturing, an undercut is a special type of recessed surface that is inaccessible using a straight tool. In turning, it refers to a recess in a diameter generally on the inside diameter of the part. In milling, it refers to a feature which is not visible when the part is viewed from the spindle. In molding, it refers to a feature that cannot be molded using only a single pull mold. In printed circuit board construction, it refers to the portion of the copper that is etched away under the photoresist.

A core is a device used in casting and moulding processes to produce internal cavities and reentrant angles. The core is normally a disposable item that is destroyed to get it out of the piece. They are most commonly used in sand casting, but are also used in die casting and injection moulding.

Surface integrity is the surface condition of a workpiece after being modified by a manufacturing process. The term was coined by Michael Field and John F. Kahles in 1964.