A biological hazard, or biohazard, is a biological substance that poses a threat to the health of living organisms, primarily humans. This could include a sample of a microorganism, virus or toxin that can adversely affect human health. A biohazard could also be a substance harmful to other living beings.

A laboratory is a facility that provides controlled conditions in which scientific or technological research, experiments, and measurement may be performed. Laboratories are found in a variety of settings such as schools, universities, privately owned research institutions, corporate research and testing facilities, government regulatory and forensic investigation centers, physicians' offices, clinics, hospitals, regional and national referral centers, and even occasionally personal residences.

A fume hood is a type of local exhaust ventilation device that is designed to prevent users from being exposed to hazardous fumes, vapors and dusts. The device is an enclosure with a movable sash window on one side that traps and exhausts gases and particulates either out of the area or back into the room, and is most frequently used in laboratory settings.

A cleanroom or clean room is an engineered space that maintains a very low concentration of airborne particulates. It is well isolated, well controlled from contamination, and actively cleansed. Such rooms are commonly needed for scientific research and in industrial production for all nanoscale processes, such as semiconductor manufacturing. A cleanroom is designed to keep everything from dust to airborne organisms or vaporised particles away from it, and so from whatever material is being handled inside it.

Ventilation is the intentional introduction of outdoor air into a space. Ventilation is mainly used to control indoor air quality by diluting and displacing indoor pollutants; it can also be used to control indoor temperature, humidity, and air motion to benefit thermal comfort, satisfaction with other aspects of the indoor environment, or other objectives.

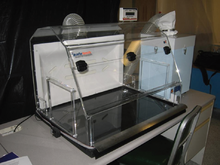

A glovebox is a sealed container that is designed to allow one to manipulate objects where a separate atmosphere is desired. Built into the sides of the glovebox are gloves arranged in such a way that the user can place their hands into the gloves and perform tasks inside the box without breaking containment. Part or all of the box is usually transparent to allow the user to see what is being manipulated. Two types of gloveboxes exist. The first allows a person to work with hazardous substances, such as radioactive materials or infectious disease agents, and the second allows manipulation of substances that must be contained within a very high purity inert atmosphere, such as argon or nitrogen. It is also possible to use a glovebox for manipulation of items in a vacuum chamber.

Occupational hygiene is the anticipation, recognition, evaluation, control, and confirmation (ARECC) of protection from risks associated with exposures to hazards in, or arising from, the workplace that may result in injury, illness, impairment, or affect the well-being of workers and members of the community. These hazards or stressors are typically divided into the categories biological, chemical, physical, ergonomic and psychosocial. The risk of a health effect from a given stressor is a function of the hazard multiplied by the exposure to the individual or group. For chemicals, the hazard can be understood by the dose response profile most often based on toxicological studies or models. Occupational hygienists work closely with toxicologists for understanding chemical hazards, physicists for physical hazards, and physicians and microbiologists for biological hazards. Environmental and occupational hygienists are considered experts in exposure science and exposure risk management. Depending on an individual's type of job, a hygienist will apply their exposure science expertise for the protection of workers, consumers and/or communities.

Process Safety Managementof Highly Hazardous Chemicals is a regulation promulgated by the U.S. Occupational Safety and Health Administration (OSHA). It defines and regulates a process safety management (PSM) program for plants using, storing, manufacturing, handling or carrying out on-site movement of hazardous materials above defined amount thresholds. Companies affected by the regulation usually build a compliant process safety management system and integrate it in their safety management system. Non-U.S. companies frequently choose on a voluntary basis to use the OSHA scheme in their business.

In electrical and safety engineering, hazardous locations are places where fire or explosion hazards may exist. Sources of such hazards include gases, vapors, dust, fibers, and flyings, which are combustible or flammable. Electrical equipment installed in such locations can provide an ignition source, due to electrical arcing, or high temperatures. Standards and regulations exist to identify such locations, classify the hazards, and design equipment for safe use in such locations.

A laminar flow cabinet or tissue culture hood is a partially enclosed bench work surface designed to prevent contamination of biological samples, semiconductor wafers, or any particle sensitive materials. Air is drawn through a HEPA filter and blown in a very smooth laminar flow in a narrow vertical curtain, separating the interior of the cabinet from the environment around it. The cabinet is usually made of stainless steel with no gaps or joints where spores might collect.

One use of the concept of biocontainment is related to laboratory biosafety and pertains to microbiology laboratories in which the physical containment of pathogenic organisms or agents is required, usually by isolation in environmentally and biologically secure cabinets or rooms, to prevent accidental infection of workers or release into the surrounding community during scientific research.

Process safety is an interdisciplinary engineering domain focusing on the study, prevention, and management of large-scale fires, explosions and chemical accidents in process plants or other facilities dealing with hazardous materials, such as refineries and oil and gas production installations. Thus, process safety is generally concerned with the prevention of, control of, mitigation of and recovery from unintentional hazardous materials releases that can have a serious effect to people, plant and/or the environment.

A biosafety cabinet (BSC)—also called a biological safety cabinet or microbiological safety cabinet—is an enclosed, ventilated laboratory workspace for safely working with materials contaminated with pathogens requiring a defined biosafety level. Several different types of BSC exist, differentiated by the degree of biocontainment they provide. BSCs first became commercially available in 1950.

The safe handling of carcinogens is the handling of cancer causing substances in a safe and responsible manner. Carcinogens are defined as 'a substance or agent that can cause cells to become cancerous by altering their genetic structure so that they multiply continuously and become malignant'. The World Health Organization breaks down the three types of carcinogens that can cause cancer in humans. The first type of carcinogen is the physical type which can be ultraviolet and ionizing radiation. The second type of carcinogens is defined as asbestos, tobacco smoke, alcohol, aflatoxin, and arsenic. The third type of carcinogen is biological which highlights infections that can be caused from viruses, bacteria, or parasites. There are many risk factors when it comes to the human body and carcinogens, which is why it is so important that the proper approach is used when attempting to reduce expose to cancer causing carcinogens.

Hierarchy of hazard control is a system used in industry to prioritize possible interventions to minimize or eliminate exposure to hazards. It is a widely accepted system promoted by numerous safety organizations. This concept is taught to managers in industry, to be promoted as standard practice in the workplace. It has also been used to inform public policy, in fields such as road safety. Various illustrations are used to depict this system, most commonly a triangle.

Chemical storage is the storage of controlled substances or hazardous materials in chemical stores, chemical storage cabinets, or similar devices.

An emergency eyewash and safety shower station are essential equipment for every laboratory that uses chemicals and hazardous substances. Emergency eyewash and safety shower stations serve the purpose of reducing workplace injury and keeping workers away from various dangers.

Engineering controls are strategies designed to protect workers from hazardous conditions by placing a barrier between the worker and the hazard or by removing a hazardous substance through air ventilation. Engineering controls involve a physical change to the workplace itself, rather than relying on workers' behavior or requiring workers to wear protective clothing.

The health and safety hazards of nanomaterials include the potential toxicity of various types of nanomaterials, as well as fire and dust explosion hazards. Because nanotechnology is a recent development, the health and safety effects of exposures to nanomaterials, and what levels of exposure may be acceptable, are subjects of ongoing research. Of the possible hazards, inhalation exposure appears to present the most concern, with animal studies showing pulmonary effects such as inflammation, fibrosis, and carcinogenicity for some nanomaterials. Skin contact and ingestion exposure, and dust explosion hazards, are also a concern.

Engineering controls for nanomaterials are a set of hazard control methods and equipment for workers who interact with nanomaterials. Engineering controls are physical changes to the workplace that isolate workers from hazards, and are considered the most important set of methods for controlling the health and safety hazards of nanomaterials after systems and facilities have been designed.