Related Research Articles

Textile is an umbrella term that includes various fiber-based materials, including fibers, yarns, filaments, threads, different fabric types, etc. At first, the word "textiles" only referred to woven fabrics. However, weaving is not the only manufacturing method, and many other methods were later developed to form textile structures based on their intended use. Knitting and non-woven are other popular types of fabric manufacturing. In the contemporary world, textiles satisfy the material needs for versatile applications, from simple daily clothing to bulletproof jackets, spacesuits, and doctor's gowns.

Weaving is a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth. Other methods are knitting, crocheting, felting, and braiding or plaiting. The longitudinal threads are called the warp and the lateral threads are the weft, woof, or filling. The method in which these threads are interwoven affects the characteristics of the cloth. Cloth is usually woven on a loom, a device that holds the warp threads in place while filling threads are woven through them. A fabric band that meets this definition of cloth can also be made using other methods, including tablet weaving, back strap loom, or other techniques that can be done without looms.

In textile production, carding is a mechanical process that disentangles, cleans and intermixes fibres to produce a continuous web or sliver suitable for subsequent processing. This is achieved by passing the fibres between differentially moving surfaces covered with "card clothing", a firm flexible material embedded with metal pins. It breaks up locks and unorganised clumps of fibre and then aligns the individual fibres to be parallel with each other. In preparing wool fibre for spinning, carding is the step that comes after teasing.

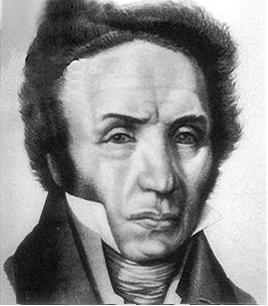

The spinning jenny is a multi-spindle spinning frame, and was one of the key developments in the industrialisation of textile manufacturing during the early Industrial Revolution. It was invented in 1764–1765 by James Hargreaves in Stan hill, Oswaldtwistle, Lancashire in England.

André Michaux was a French botanist and explorer. He is most noted for his study of North American flora. In addition Michaux collected specimens in England, Spain, France, and even Persia. His work was part of a larger European effort to gather knowledge about the natural world. Michaux's contributions include Histoire des chênes de l'Amérique and Flora Boreali-Americana which continued to be botanical references well into the 19th century. His son, François André Michaux, also became an authoritative botanist.

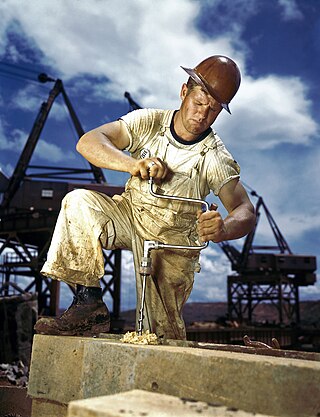

Overalls or bib-and-brace overalls, also called dungarees in British English, are a type of garment usually used as protective clothing when working. The garments are commonly referred to as a "pair of overalls" by analogy with "pair of trousers".

John Kay was an English inventor whose most important creation was the flying shuttle, which was a key contribution to the Industrial Revolution. He is often confused with his namesake, who built the first "spinning frame".

Flannel is a soft woven fabric, of varying fineness. Flannel was originally made from carded wool or worsted yarn, but is now often made from either wool, cotton, or synthetic fiber. Flannel is commonly used to make tartan clothing, blankets, bed sheets, sleepwear, and several other uses.

Textile design, also known as textile geometry, is the creative and technical process by which thread or yarn fibers are interlaced to form a piece of cloth or fabric, which is subsequently printed upon or otherwise adorned. Textile design is further broken down into three major disciplines: printed textile design, woven textile design, and mixed media textile design. Each uses different methods to produce a fabric for variable uses and markets. Textile design as an industry is involved in other disciplines such as fashion, interior design, and fine arts.

A staple fiber is a textile fiber of discrete length. The opposite is a filament fiber, which comes in continuous lengths. Staple length is a characteristic fiber length of a sample of staple fibers. It is an essential criterion in yarn spinning, and aids in cohesion and twisting. Compared to synthetic fibers, natural fibers tend to have different and shorter lengths. The quality of natural fibers like cotton is categorized into staple length such as short, medium, long staple, and extra-long. Gossypium barbadense, one of several cotton species, produces extra-long staple fibers. The staple fibers may be obtained from natural and synthetic sources. In the case of synthetics and blends, the filament yarns are cut to a predetermined length.

The textile bleaching is one of the steps in the textile manufacturing process. The objective of bleaching is to remove the natural color for the following steps such as dyeing or printing or to achieve full white. All raw textile materials, when they are in natural form, are known as 'greige' material. They have their natural color, odor and impurities that are not suited to clothing materials. Not only the natural impurities will remain in the greige material, but also the add-ons that were made during its cultivation, growth and manufacture in the form of pesticides, fungicides, worm killers, sizes, lubricants, etc. The removal of these natural coloring matters and add-ons during the previous state of manufacturing is called scouring and bleaching.

Herringbone, also called broken twill weave, describes a distinctive V-shaped weaving pattern usually found in twill fabric. It is distinguished from a plain chevron by the break at reversal, which makes it resemble a broken zigzag. The pattern is called herringbone because it resembles the skeleton of a herring fish. Herringbone-patterned fabric is usually wool, and is one of the most popular cloths used for suits and outerwear. Tweed cloth is often woven with a herringbone pattern.

The homespun movement was started in 1767 by Quakers in Boston, Massachusetts, to encourage the purchase of goods, especially apparel, manufactured in the American Colonies. The movement was created in response to the British Townshend Acts of 1767 and 1768, in the early stages of the American Revolution.

Sussi or susi is a term for multicolored striped or checked cloth produced mainly in Sindh. Sussi is thin handloom fabric made of cotton, silk, or a blend of the two, with colored warp stripes. Sindh region was known for its production and exports during the Mughal period. Sussi was most often made with red and blue, blue and white, or green and white stripes, but other patterns were also produced. The fabric was exported to England, where sousaes were in great demand in the 18th century.

Piece goods were the textile materials sold in cut pieces as per the buyer's specification. The piece goods were either cut from a fabric roll or produced with a certain length, also called yard goods. Various textiles such as cotton, wool, silk, etc., were traded in terms of piece goods. The prices were determined as per the fabric quality.

Greige goods are loom state woven fabrics, or unprocessed knitted fabrics. Greige goods undergo many subsequent processes, for instance, dyeing, printing, bleaching, and finishing, prior to further converting to finished goods such as clothing, or other textile products. "Grey fabrics" is another term to refer to unfinished woven or knitted fabrics.

Negro cloth or Lowell cloth was a coarse and strong cloth used for slaves' clothing in the West Indies and the Southern Colonies. The cloth was imported from Europe in the 18th and 19th centuries.

Anabasse was a coarse woolen material, a kind of blanketing made in France and the Netherlands for the African market, or a type of coarse blanketing made in Lancashire using a wool warp and a cotton weft.

Bay was a napped coarse woolen fabric, not technically considered cloth, introduced to England by Flemish immigrants in the 16th century. It was produced in Essex at Colchester and Bocking, and also in various towns in the West of England. Production continued until the 19th century. Bays were made into linings for furniture, hangings, curtains, bed surroundings, and cloaks.

A blend is a mixture of two or more fibers. In yarn spinning, different compositions, lengths, diameters, or colors may be combined to create a blend. Blended textiles are fabrics or yarns produced with a combination of two or more types of different fibers, or yarns to obtain desired traits and aesthetics. Blending is possible at various stages of textile manufacturing. The term, blend, refers to spun fibers or a fabric composed of such fibers. There are several synonymous terms: a combination yarn is made up of two strands of different fibers twisted together to form a ply; a mixture or mixed cloth refers to blended cloths in which different types of yarns are used in warp and weft sides.

References

- ↑ Bishop, John Leander (1868). A History of American Manufactures from 1608 to 1860...: Comprising Annals of the Industry of the United States in Machinery, Manufactures and Useful Arts, with a Notice of the Important Inventions, Tariffs, and the Results of Each Decennial Census. E. Young & Company. p. 343.

- 1 2 3 Montgomery, Florence M. (1984). Textiles in America 1650-1870 : a dictionary based on original documents, prints and paintings, commercial records, American merchants' papers, shopkeepers' advertisements, and pattern books with original swatches of cloth. New York; London: Norton. p. 372. ISBN 978-0-393-01703-8.

- ↑ ''From the early eighteenth century, references to " Virginia cloth " begin to appear with more frequency in records of the colony, indicating the extent to which linen and wool, as well as cotton, were being grown and manufactured, Inventories '' Page 127 https://books.google.com/books?id=8vdCAAAAIAAJ&q=virginia+cloth

- ↑ Institute, Virginia Polytechnic (1933). Virginia: Economic and Civic. Whittet & Shepperson. p. 10.

- ↑ The world of the American Revolution : a daily life encyclopedia. Merril D. Smith. Santa Barbara, California. 2015. ISBN 978-1-4408-3027-3. OCLC 881400789.

{{cite book}}: CS1 maint: location missing publisher (link) CS1 maint: others (link) - ↑ The American Revolution : a heritage of change. John Parker, Carol Louise Urness, James Ford Bell Library. Minneapolis: Associates of the James Ford Bell Library. 1975. ISBN 978-1-85109-739-5. OCLC 2296773.

{{cite book}}: CS1 maint: others (link) - ↑ Royster, Charles; Abbot, W. W. (1996). "The Papers of George Washington. Colonial Series. [Volume] 7: January 1761-June 1767; [Volume] 8: June 1767-December 1771; [Volume] 9: January 1772-March 1774; [Volume] 10: March 1774-June 1775". The Journal of Southern History. 62 (4): 795. doi:10.2307/2211148. ISSN 0022-4642. JSTOR 2211148.