A laser is a device that emits light through a process of optical amplification based on the stimulated emission of electromagnetic radiation. The word laser originated as an acronym for light amplification by stimulated emission of radiation. The first laser was built in 1960 by Theodore Maiman at Hughes Research Laboratories, based on theoretical work by Charles H. Townes and Arthur Leonard Schawlow and the optical amplifier patented by Gordon Gould.

A laser diode is a semiconductor device similar to a light-emitting diode in which a diode pumped directly with electrical current can create lasing conditions at the diode's junction.

Photonics is a branch of optics that involves the application of generation, detection, and manipulation of light in the form of photons through emission, transmission, modulation, signal processing, switching, amplification, and sensing.

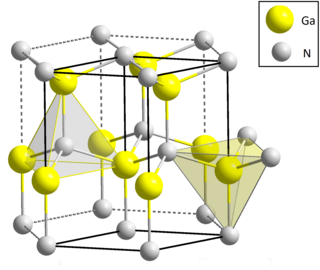

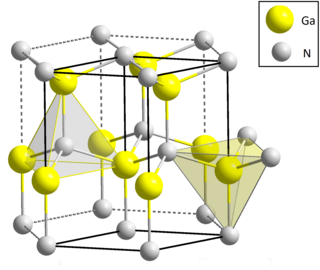

Gallium nitride is a binary III/V direct bandgap semiconductor commonly used in blue light-emitting diodes since the 1990s. The compound is a very hard material that has a Wurtzite crystal structure. Its wide band gap of 3.4 eV affords it special properties for applications in optoelectronics, high-power and high-frequency devices. For example, GaN is the substrate that makes violet (405 nm) laser diodes possible, without requiring nonlinear optical frequency doubling.

A blue laser emits electromagnetic radiation with a wavelength between 400 and 500 nanometers, which the human eye sees in the visible spectrum as blue or violet.

A solid-state laser is a laser that uses a gain medium that is a solid, rather than a liquid as in dye lasers or a gas as in gas lasers. Semiconductor-based lasers are also in the solid state, but are generally considered as a separate class from solid-state lasers, called laser diodes.

Jenoptik AG is a Jena, Germany-based integrated photonics company. The company is listed on the Frankfurt Stock Exchange and is included in the TecDAX stock index.

The role of the substrate in power electronics is to provide the interconnections to form an electric circuit, and to cool the components. Compared to materials and techniques used in lower power microelectronics, these substrates must carry higher currents and provide a higher voltage isolation. They also must operate over a wide temperature range.

A photonic integrated circuit (PIC) or integrated optical circuit is a microchip containing two or more photonic components that form a functioning circuit. This technology detects, generates, transports, and processes light. Photonic integrated circuits use photons as opposed to electrons that are used by electronic integrated circuits. The major difference between the two is that a photonic integrated circuit provides functions for information signals imposed on optical wavelengths typically in the visible spectrum or near-infrared (850–1650 nm).

IPG Photonics Corporation is a manufacturer of fiber lasers. IPG Photonics developed and commercialized optical fiber lasers, which are used in a variety of applications including materials processing, medical applications and telecommunications. IPG has manufacturing facilities in the United States, Germany, Russia and Italy.

Osram Opto Semiconductors GmbH of Regensburg, Germany, was a wholly owned subsidiary of Osram GmbH, which was the world's second largest manufacturer of optoelectronic semiconductors after Nichia and followed in third place by Cree Inc. The company was founded in 1999 as a joint venture between Osram and Infineon Technologies. In 2021 Osram Opto Semiconductors was integrated to AMS-Osram International GmbH and is now part of the AMS Osram Group.

The Berthold Leibinger Innovationspreis is an award for given to those who have created applied laser technology and innovations on the application or generation of laser light. It is open to participants worldwide. It is biennially awarded by the German non-profit foundation Berthold Leibinger Stiftung. Three prizes are awarded worth 100,000 euros. The prize winners are selected from eight finalists that present their work person in a jury session. The jury is composed of international experts from different fields.

Semikron is a German-based independent manufacturer of power semiconductor components. The company was founded in 1951 by Dr. Friedrich Josef Martin in Nuremberg. In 2019, the company had a staff of more than 3,000 people in 24 subsidiaries (world-wide) with production sites in Germany, Brazil, China, France, India, Italy, Slovakia, and the USA.

The IEEE Photonics Award is a Technical Field Award established by the IEEE Board of Directors in 2002. This award is presented for outstanding achievements in photonics, including work relating to: light-generation, transmission, deflection, amplification and detection and the optical/electro-optical componentry and instrumentation used to accomplish these functions. Also included are storage technologies utilizing photonics to read or write data and optical display technologies. It also extends from energy generation/propagation, communications, information processing, storage and display, biomedical and medical uses of light and measurement applications.

Crosslight Software Inc. is an international company headquartered in greater Vancouver, British Columbia, Canada. Officially spun off from the National Research Council of Canada (NRC) in 1995, it provides Technology Computer Aided Design (TCAD) tools for semiconductor device and process simulations.

Nanoneedles may be conical or tubular needles in the nanometre size range, made from silicon or boron-nitride with a central bore of sufficient size to allow the passage of large molecules, or solid needles useful in Raman spectroscopy, light emitting diodes (LED) and laser diodes.

Amada Weld Tech, a subsidiary of Amada Weld Tech Co., Ltd., designs and manufactures equipment and systems for resistance welding, laser welding, laser marking, laser cutting, laser micro machining, hermetic sealing, micro tig welding, and hot bar reflow soldering and bonding. Established in 1948, AMADA WELD TECH is headquartered in Monrovia, California, US. The company's equipment is used in numerous industries, chiefly medical, aerospace, automotive, battery production, and electronic component manufacturing. Amada Weld Tech has approximately 200 employees, with 7 sales and manufacturing offices serving about 12,000 customers worldwide. More than 80,000 items are manufactured annually. The company is certified to ISO 9001:2015, China Compulsory Certificate (CCC), European Conformity (CE), and Canadian Standards Association (CSA) quality certifications.

The Fraunhofer Center for High Temperature Materials and Design is a research center of the Fraunhofer Institute for Silicate Research in Würzburg, a research institute of the Fraunhofer Society. It predominantly conducts research in high temperature technologies energy-efficient heating processes and thus contributes to sustainable technological progress. It is headquartered in Bayreuth and has additional locations in Würzburg and Münchberg.