Related Research Articles

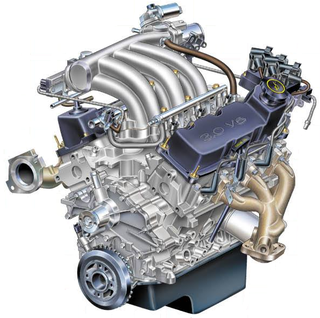

A V6 engine is a six-cylinder piston engine where the cylinders share a common crankshaft and are arranged in a V configuration.

The Ford 335 engine family was a group of engines built by the Ford Motor Company between 1969 and 1982. The "335" designation reflected Ford management's decision to produce an engine of that size with room for expansion during its development. This engine family began production in late 1969 with a 351 cu in (5.8 L) engine, commonly called the 351C. It later expanded to include a 400 cu in (6.6 L) engine which used a taller version of the engine block, commonly referred to as a tall deck engine block, a 351 cu in (5.8 L) tall deck variant, called the 351M, and a 302 cu in (4.9 L) engine which was exclusive to Australia.

The Ford small-block is a series of 90° overhead valve small-block V8 automobile engines manufactured by the Ford Motor Company from July 1961 to December 2000.

The Ford Modular engine is Ford Motor Company's overhead camshaft (OHC) V8 and V10 gasoline-powered small block engine family. Introduced in 1990, the engine family received its “modular” designation by Ford for its new approach to the setup of tooling and casting stations in the Windsor and Romeo engine manufacturing plants.

The initial design development for the PowerTech V6 and V8 engine family was done by American Motors Corporation (AMC) and debuted in 1998 with credit to Chrysler. This was the first new V8 engine for Chrysler since the 1960s. The companion V6 was basically the V8 with two fewer cylinders, another concept that originated at AMC before the company joined Chrysler. These new engines had nothing in common with the Chrysler A engine V8s, nor the Jeep 4.0 L "PowerTech" I6 engine.

The Jaguar AJ-8 is a compact DOHC V8 piston engine used in many Jaguar vehicles. It was the fourth new engine type in the history of the company. It was an in house design with work beginning before Ford's purchase of the company. In 1997 it replaced both designs previously available on Jaguar cars: the straight-6 Jaguar AJ6 engine, and the Jaguar V12 engine. It remained the only engine type available on Jaguar until 1999 with the launch of the S-Type, when the Jaguar AJ-V6 engine was added to the list. The AJ-V8 is available in displacements ranging from 3.2L to 5.0L, and a supercharged version is also produced. Ford Motor Company also used this engine in other cars, including the Lincoln LS and the 2002–2005 Ford Thunderbird, as well as in several Land Rovers, and the Aston Martin V8 Vantage.

The Buick V6 is an OHV V6 engine developed by the Buick division of General Motors and first introduced in 1962. The engine was originally 198 cu in (3.2 L) and was marketed as the Fireball engine. GM continued to develop and refine the 3.8 L (230 cu in) V6, eventually and commonly referred to simply as the 3800, through numerous iterations.

The Ford Vulcan is a 3.0 L V6 engine designed and built by the Ford Motor Company. It debuted in 1986 in the newly launched Ford Taurus. Ford went on to install the Vulcan V6 in a variety of car, van, and pickup truck models until the 2008 model year, after which production stopped.

The Ford Super High Output (SHO) V8 engine was designed and built by Ford Motor Company in conjunction with Yamaha Motor Corporation for use in the 1996 Ford Taurus SHO. It was based on the successful Ford Duratec engine rather than its predecessor, the compact Ford SHO V6 engine developed by Yamaha for the 1989 Taurus SHO. The engine was retired in 1999 when production of the third-generation Taurus SHO ended.

The Essex V6 is a 90° V6 engine family built by the Ford Motor Company at the Essex Engine Plant in Windsor, Ontario, Canada. This engine is unrelated to Ford's British Essex V6. Introduced in 1982, versions of the Essex V6 engine family were used in subcompact through to large cars, vans, minivans, and some pickup trucks. The Essex V6 was last used in the 2008 regular-cab F-150, after which it was succeeded by a version of the Ford Cyclone engine. An industrial version of the engine was available until 2015.

The Oldsmobile V8, also referred to as the Rocket, is a series of engines that was produced by Oldsmobile from 1949 until 1990. The Rocket, along with the 1949 Cadillac V8, were the first post-war OHV crossflow cylinder head V8 engines produced by General Motors. Like all other GM divisions, Olds continued building its own V8 engine family for decades, adopting the corporate Chevrolet 350 small-block and Cadillac Northstar engine only in the 1990s. All Oldsmobile V8s were manufactured at plants in Lansing, Michigan while the engine block and cylinder heads were cast at Saginaw Metal Casting Operations.

The Ford flathead V8 is a V8 engine with a flat cylinder head designed by the Ford Motor Company and built by Ford and various licensees. During the engine's first decade of production, when overhead-valve engines were used by only a small minority of makes, it was usually known simply as the Ford V‑8, and the first car model in which it was installed, the Model 18, was often called simply the "Ford V-8", after its new engine. Although the V8 configuration was not new when the Ford V8 was introduced in 1932, the latter was a market first in the respect that it made an 8-cylinder affordable and a V engine affordable to the emerging mass market consumer for the first time. It was the first independently designed and built V8 engine produced by Ford for mass production, and it ranks as one of the company's most important developments. A fascination with ever-more-powerful engines was perhaps the most salient aspect of the American car and truck market for a half century, from 1923 until 1973. The engine was intended to be used for big passenger cars and trucks; it was installed in such until 1953, making the engine's 21-year production run for the U.S. consumer market longer than the 19-year run of the Ford Model T engine for that market. The engine was on Ward's list of the 10 best engines of the 20th century. It was a staple of hot rodders in the 1950s, and it remains famous in the classic car hobbies even today, despite the huge variety of other popular V8s that followed.

The Ford Motor Company produced straight-six engines from 1906 until 1908 and from 1941 until 2016. In 1906, the first Ford straight-six was introduced in the Model K. The next was introduced in the 1941 Ford. Ford continued producing straight-six engines for use in its North American vehicles until 1996, when they were discontinued in favor of more compact V6 designs.

In an internal combustion engine, the engine block is the structure which contains the cylinders and other components. In an early automotive engine, the engine block consisted of just the cylinder block, to which a separate crankcase was attached. Modern engine blocks typically have the crankcase integrated with the cylinder block as a single component. Engine blocks often also include elements such as coolant passages and oil galleries.

Boss is the internal name for a family of large-displacement V8 engines from Ford Motor Company intended to compete with Chrysler's Hemi and General Motors' 6.0 L Vortec engines. Originally, Ford developed the engine architecture under the name Hurricane; however, development of the engine was delayed because of its temporary cancellation in 2005. It was revived in early 2006 by Mark Fields and was given the new name of Boss in light of the devastation caused by Hurricane Katrina in 2005. In spite of this change, Ford did not officially market the engines with the Boss name in any production vehicle where they were used, instead referring to the engines by their displacement.

A V8 engine is an eight-cylinder piston engine in which two banks of four cylinders share a common crankshaft and are arranged in a V configuration.

Essex Engine Plant is a Ford factory located in Windsor, Ontario, Canada. It currently produces Ford's 5.0L V8 engine. The plant was built in 1981 to produce Ford's Essex V6 engine.

Saginaw Metal Casting Operations is an automobile engine foundry plant in Saginaw, Michigan. Opened under GM management in 1919, the factory produces engine blocks and cylinder heads for General Motors vehicles. The factory currently occupies 1.9 million square feet on 490 acres. Historically in September 1927 it was known as the Chevrolet Grey Iron Foundry. In the past when it was called GM-Saginaw Product Company (SPC) a cloverleaf casting symbol mark was cast onto the iron component.

References

- 1 2 3 4 "Ford closes Windsor casting plant". Autos.ca. May 30, 2007. Retrieved October 14, 2018.

- ↑ "Production Ends at Historic Windor Casting Plant".

- ↑ "The Novak Guide to the Ford Windsor V8 Engines".

- 1 2 "Windsor Casting Plant". Ford Motor Company. Archived from the original on March 11, 2007.