Related Research Articles

Petroleum engineering is a field of engineering concerned with the activities related to the production of Hydrocarbons, which can be either crude oil or natural gas. Exploration and production are deemed to fall within the upstream sector of the oil and gas industry. Exploration, by earth scientists, and petroleum engineering are the oil and gas industry's two main subsurface disciplines, which focus on maximizing economic recovery of hydrocarbons from subsurface reservoirs. Petroleum geology and geophysics focus on provision of a static description of the hydrocarbon reservoir rock, while petroleum engineering focuses on estimation of the recoverable volume of this resource using a detailed understanding of the physical behavior of oil, water and gas within porous rock at very high pressure.

The Salt Creek Oil Field is located in Natrona County, Wyoming. By 1970, more oil had been produced by this field than any other in the Rocky Mountains region and accounted for 20 percent of the total production in Wyoming.

A petroleum reservoir or oil and gas reservoir is a subsurface accumulation of hydrocarbons contained in porous or fractured rock formations.

Enhanced oil recovery, also called tertiary recovery, is the extraction of crude oil from an oil field that cannot be extracted otherwise. Although the primary and secondary recovery techniques rely on the pressure differential between the surface and the underground well, enhanced oil recovery functions by altering the chemical composition of the oil itself in order to make it easier to extract. EOR can extract 30% to 60% or more of a reservoir's oil, compared to 20% to 40% using primary and secondary recovery. According to the US Department of Energy, carbon dioxide and water are injected along with one of three EOR techniques: thermal injection, gas injection, and chemical injection. More advanced, speculative EOR techniques are sometimes called quaternary recovery.

Steam-assisted gravity drainage is an enhanced oil recovery technology for producing heavy crude oil and bitumen. It is an advanced form of steam stimulation in which a pair of horizontal wells is drilled into the oil reservoir, one a few metres above the other. High pressure steam is continuously injected into the upper wellbore to heat the oil and reduce its viscosity, causing the heated oil to drain into the lower wellbore, where it is pumped out. Dr. Roger Butler, engineer at Imperial Oil from 1955 to 1982, invented the steam assisted gravity drainage (SAGD) process in the 1970s. Butler "developed the concept of using horizontal pairs of wells and injected steam to develop certain deposits of bitumen considered too deep for mining". In 1983 Butler became director of technical programs for the Alberta Oil Sands Technology and Research Authority (AOSTRA), a crown corporation created by Alberta Premier Lougheed to promote new technologies for oil sands and heavy crude oil production. AOSTRA quickly supported SAGD as a promising innovation in oil sands extraction technology.

Carbon dioxide (CO2) flooding is a process in which carbon dioxide is injected into an oil reservoir to increase the output when extracting oil. This is most often used in reservoirs where production rates have declined due to depletion.

The South Belridge Oil Field is a large oil field in northwestern Kern County, San Joaquin Valley, California, about forty miles west of Bakersfield. Discovered in 1911, and having a cumulative production of over 1,500 million barrels (240,000,000 m3) of oil at the end of 2008, it is the fourth-largest oil field in California, after the Midway-Sunset Oil Field, Kern River Oil Field, and Wilmington Oil Field, and is the sixth-most productive field in the United States. Its estimated remaining reserves, as of the end of 2008, were around 494 million barrels (78,500,000 m3), the second-largest in the state, and it had 6,253 active wells. The principal operator on the field was Aera Energy LLC, a joint venture between Royal Dutch Shell and ExxonMobil. Additionally, the field included the only onshore wells in California owned and operated by ExxonMobil.

The Kern Front Oil Field is a large oil and gas field in the lower Sierra Nevada foothills in Kern County, California. Discovered in 1912, and with a cumulative production of around 210 million barrels (33,000,000 m3) of oil, it ranks 29th in size in the state, and is believed to retain approximately ten percent of its original oil, according to the official estimates of the California Department of Oil, Gas, and Geothermal Resources (DOGGR). It is adjacent to the much larger Kern River Oil Field, which is to the southeast, and the Mount Poso Oil Field to the north.

Heavy oil production is a developing technology for extracting heavy oil in industrial quantities. Estimated reserves of heavy oil are over 6 trillion barrels, three times that of conventional oil and gas.

The Miller oilfield is a deep reservoir under the North Sea, 240 kilometres north-east of Peterhead in UKCS Blocks 16/7b and 16/8b. It was discovered in 1983 by BP in a water depth of 100 metres. Production from Miller field started in June 1992, and plateau production was from late 1992 to 1997 at rates of up to 150,000 barrels (24,000 m3) of oil and 255 million cu ft (7.2 million m3) of gas per day at standard conditions. Miller produced some 345 million barrels (54,900,000 m3) of oil during its lifetime. The field is named after Hugh Miller who contributed to Scottish geology in the early nineteenth century.

Downhole oil–water separation (DOWS) technologies are apparatuses and methods that separate production fluids into a petroleum-rich stream and water-rich stream within an oil well. A DOWS system installed in a borehole will receive the fluids from an oil-producing zone in an oil reservoir and separate the mixture into a stream that is mostly water and a stream that is primarily crude oil and natural gas and direct the streams to different destinations. After the separation in the borehole, DOWS systems pump the petroleum-rich stream to the surface and inject the water-rich stream into a different zone or formation accessible to the same wellbore.

The Batı Raman oil field (batı meaning west in Turkish) is located in Batman Province, in the Southeastern Anatolia Region of Turkey. With estimated reserves of 1.85 billion barrels (252×106 tonnes) and a production rate of around 7,500 barrels per day (1,190 m3/d) from 300 wells (as of 2007), it is the largest and most productive oil field in Turkey.

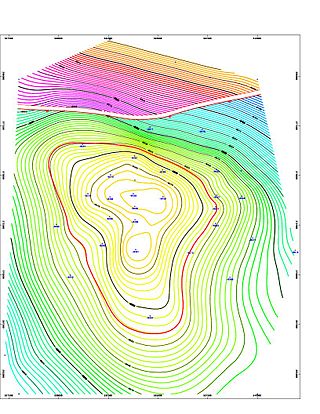

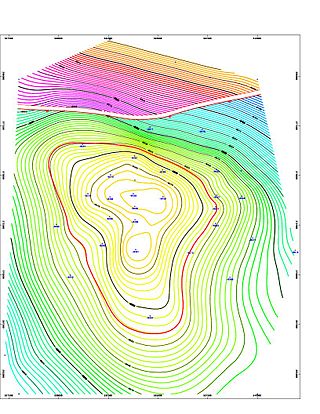

The Garzan oil field is an oil field located in Batman, Batman Province, Southeastern Anatolia Region. It was discovered in 1947–1951 and developed by Türkiye Petrolleri Anonim Ortaklığı. It began production in 1956. The total proven reserves of the Garzan oil field are around 163 million barrels (22.2×106 tonnes), and production is about 1,700 barrels per day (270 m3/d). The structure is a double plunging anticline bordered by a major reverse fault extending along the southern flank. The age of the Garzan formation is cretaceous, consisting of carbonates of a rudist build-up complex. Oil field contains 24 degree API (0.91 g/cm3) oil with a reservoir viscosity of 6.75 cp. Reservoir was initially highly undersaturated lists basic reservoirdata for Garzan.

Tight oil is light crude oil contained in unconventional petroleum-bearing formations of low permeability, often shale or tight sandstone. Economic production from tight oil formations requires the same hydraulic fracturing and often uses the same horizontal well technology used in the production of shale gas. While sometimes called "shale oil", tight oil should not be confused with oil shale or shale oil. Therefore, the International Energy Agency recommends using the term "light tight oil" for oil produced from shales or other very low permeability formations, while the World Energy Resources 2013 report by the World Energy Council uses the terms "tight oil" and "shale-hosted oil".

Mohamed Yousef Soliman is a professor and the former chairperson of the department of Petroleum Engineering at Texas Tech University. After working for Halliburton for 32 years, he joined Texas Tech in January 2011. He obtained his bachelor's degree in petroleum engineering from Cairo University in 1971. Having completed his bachelor's degree he came to the United States to continue higher education. He received his master's degree and doctorate degrees, both in Petroleum engineering, from Stanford University in 1975 and 1978 His M. S. Thesis was "Rheological Properties of Emulsion Flowing Through Capillary Tubes Under Turbulent Conditions,"; his PhD thesis, "Numerical Modeling of Thermal Recovery Processes."

Riyaz Kharrat is an eminent Iranian scientist in the field of chemical engineering and petroleum engineering. He is a full professor at Montanuniversität Leoben.

Microbial enhanced oil recovery (MEOR) is a biological based technology consisting in manipulating function or structure, or both, of microbial environments existing in oil reservoirs. The ultimate aim of MEOR is to improve the recovery of oil entrapped in porous media while increasing economic profits. MEOR is a tertiary oil extraction technology allowing the partial recovery of the commonly residual two-thirds of oil, thus extending the life of mature oil reservoirs.

Baghir A. Suleimanov — Petroleum Scientist, Doctor of Technical Sciences, Professor, Corresponding Member of Azerbaijan National Academy of Sciences

Oilfield scale inhibition is the process of preventing the formation of scale from blocking or hindering fluid flow through pipelines, valves, and pumps used in oil production and processing. Scale inhibitors (SIs) are a class of specialty chemicals that are used to slow or prevent scaling in water systems. Oilfield scaling is the precipitation and accumulation of insoluble crystals (salts) from a mixture of incompatible aqueous phases in oil processing systems. Scale is a common term in the oil industry used to describe solid deposits that grow over time, blocking and hindering fluid flow through pipelines, valves, pumps etc. with significant reduction in production rates and equipment damages. Scaling represents a major challenge for flow assurance in the oil and gas industry. Examples of oilfield scales are calcium carbonate (limescale), iron sulfides, barium sulfate and strontium sulfate. Scale inhibition encompasses the processes or techniques employed to treat scaling problems.

Oil and gas reserves denote discovered quantities of crude oil and natural gas that can be profitably produced/recovered from an approved development. Oil and gas reserves tied to approved operational plans filed on the day of reserves reporting are also sensitive to fluctuating global market pricing. The remaining resource estimates are likely sub-commercial and may still be under appraisal with the potential to be technically recoverable once commercially established. Natural gas is frequently associated with oil directly and gas reserves are commonly quoted in barrels of oil equivalent (BoE). Consequently, both oil and gas reserves, as well as resource estimates, follow the same reporting guidelines, and are referred to collectively hereinafter as oil & gas.

References

- ↑ Bardon C. P., Karaoguz D., Tholance M., “Well stimulation by CO2 in the heavyoil field of Camurlu in Turkey”, SPE Enhanced Oil Recovery Symposium,20–23 April 1986, Tulsa, Oklahoma, 14943-MS.

- ↑ Bardon C. P., Karaoguz D., Tholance M., “Well stimulation by CO2 in the heavyoil field of Camurlu in Turkey”, SPE Enhanced Oil Recovery Symposium,20–23 April 1986, Tulsa, Oklahoma, 14943-MS.

- ↑ Bardon C. P., Karaoguz D., Tholance M., “Well stimulation by CO2 in the heavyoil field of Camurlu in Turkey”, SPE Enhanced Oil Recovery Symposium,20–23 April 1986, Tulsa, Oklahoma, 14943-MS.

- ↑ Gondiken S., “Camurlu field immiscible CO2 huffand puff pilot project”, SPE 15749, 1987