A nuclear electric rocket is a type of spacecraft propulsion system where thermal energy from a nuclear reactor is converted to electrical energy, which is used to drive an ion thruster or other electrical spacecraft propulsion technology. The nuclear electric rocket terminology is slightly inconsistent, as technically the "rocket" part of the propulsion system is non-nuclear and could also be driven by solar panels. This is in contrast with a nuclear thermal rocket, which directly uses reactor heat to add energy to a working fluid, which is then expelled out of a rocket nozzle.

A four-strokeengine is an internal combustion (IC) engine in which the piston completes four separate strokes while turning the crankshaft. A stroke refers to the full travel of the piston along the cylinder, in either direction. The four separate strokes are termed:

- Intake: Also known as induction or suction. This stroke of the piston begins at top dead center (T.D.C.) and ends at bottom dead center (B.D.C.). In this stroke the intake valve must be in the open position while the piston pulls an air-fuel mixture into the cylinder by producing a partial vacuum in the cylinder through its downward motion.

- Compression: This stroke begins at B.D.C, or just at the end of the suction stroke, and ends at T.D.C. In this stroke the piston compresses the air-fuel mixture in preparation for ignition during the power stroke (below). Both the intake and exhaust valves are closed during this stage.

- Combustion: Also known as power or ignition. This is the start of the second revolution of the four stroke cycle. At this point the crankshaft has completed a full 360 degree revolution. While the piston is at T.D.C. the compressed air-fuel mixture is ignited by a spark plug or by heat generated by high compression, forcefully returning the piston to B.D.C. This stroke produces mechanical work from the engine to turn the crankshaft.

- Exhaust: Also known as outlet. During the exhaust stroke, the piston, once again, returns from B.D.C. to T.D.C. while the exhaust valve is open. This action expels the spent air-fuel mixture through the exhaust port.

A combined cycle power plant is an assembly of heat engines that work in tandem from the same source of heat, converting it into mechanical energy. On land, when used to make electricity the most common type is called a combined cycle gas turbine (CCGT) plant. The same principle is also used for marine propulsion, where it is called a combined gas and steam (COGAS) plant. Combining two or more thermodynamic cycles improves overall efficiency, which reduces fuel costs.

Internal combustion engine cooling uses either air or liquid to remove the waste heat from an internal combustion engine. For small or special purpose engines, cooling using air from the atmosphere makes for a lightweight and relatively simple system. Watercraft can use water directly from the surrounding environment to cool their engines. For water-cooled engines on aircraft and surface vehicles, waste heat is transferred from a closed loop of water pumped through the engine to the surrounding atmosphere by a radiator.

Cogeneration or combined heat and power (CHP) is the use of a heat engine or power station to generate electricity and useful heat at the same time.

Energy transformation, also known as energy conversion, is the process of changing energy from one form to another. In physics, energy is a quantity that provides the capacity to perform work or moving or provides heat. In addition to being converted, according to the law of conservation of energy, energy is transferable to a different location or object, but it cannot be created or destroyed.

Micro combined heat and power, micro-CHP, µCHP or mCHP is an extension of the idea of cogeneration to the single/multi family home or small office building in the range of up to 50 kW. Usual technologies for the production of heat and power in one common process are e.g. internal combustion engines, micro gas turbines, stirling engines or fuel cells.

In thermodynamics, the thermal efficiency is a dimensionless performance measure of a device that uses thermal energy, such as an internal combustion engine, steam turbine, steam engine, boiler, furnace, refrigerator, ACs etc.

Waste heat is heat that is produced by a machine, or other process that uses energy, as a byproduct of doing work. All such processes give off some waste heat as a fundamental result of the laws of thermodynamics. Waste heat has lower utility than the original energy source. Sources of waste heat include all manner of human activities, natural systems, and all organisms, for example, incandescent light bulbs get hot, a refrigerator warms the room air, a building gets hot during peak hours, an internal combustion engine generates high-temperature exhaust gases, and electronic components get warm when in operation.

Energy recovery includes any technique or method of minimizing the input of energy to an overall system by the exchange of energy from one sub-system of the overall system with another. The energy can be in any form in either subsystem, but most energy recovery systems exchange thermal energy in either sensible or latent form.

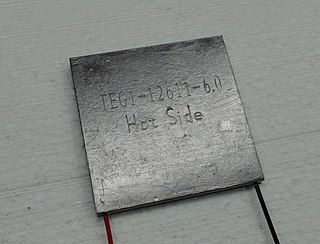

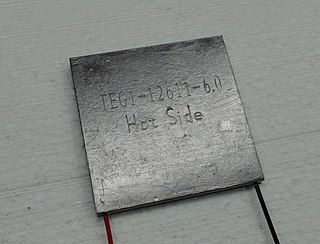

A thermoelectric generator (TEG), also called a Seebeck generator, is a solid state device that converts heat directly into electrical energy through a phenomenon called the Seebeck effect. Thermoelectric generators function like heat engines, but are less bulky and have no moving parts. However, TEGs are typically more expensive and less efficient.

A waste heat recovery unit (WHRU) is an energy recovery heat exchanger that transfers heat from process outputs at high temperature to another part of the process for some purpose, usually increased efficiency. The WHRU is a tool involved in cogeneration. Waste heat may be extracted from sources such as hot flue gases from a diesel generator, steam from cooling towers, or even waste water from cooling processes such as in steel cooling.

A liquid nitrogen vehicle is powered by liquid nitrogen, which is stored in a tank. Traditional nitrogen engine designs work by heating the liquid nitrogen in a heat exchanger, extracting heat from the ambient air and using the resulting pressurized gas to operate a piston or rotary motor. Vehicles propelled by liquid nitrogen have been demonstrated, but are not used commercially. One such vehicle, Liquid Air, was demonstrated in 1902.

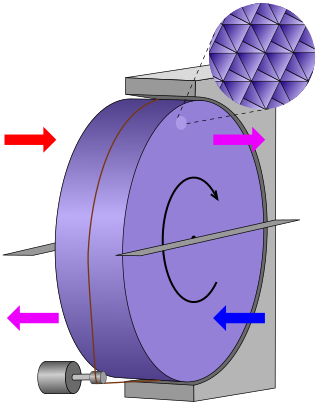

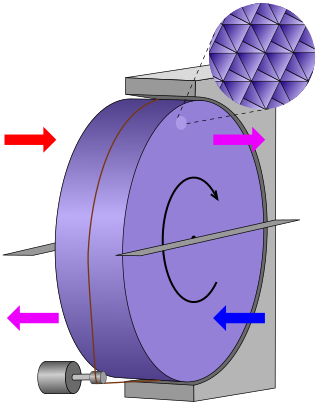

A thermal wheel, also known as a rotary heat exchanger, or rotary air-to-air enthalpy wheel, energy recovery wheel, or heat recovery wheel, is a type of energy recovery heat exchanger positioned within the supply and exhaust air streams of air-handling units or rooftop units or in the exhaust gases of an industrial process, in order to recover the heat energy. Other variants include enthalpy wheels and desiccant wheels. A cooling-specific thermal wheel is sometimes referred to as a Kyoto wheel.

Applications of the Stirling engine range from mechanical propulsion to heating and cooling to electrical generation systems. A Stirling engine is a heat engine operating by cyclic compression and expansion of air or other gas, the "working fluid", at different temperature levels such that there is a net conversion of heat to mechanical work. The Stirling cycle heat engine can also be driven in reverse, using a mechanical energy input to drive heat transfer in a reversed direction.

Alphabet Energy was a startup company founded in 2009 at the University of California, Berkeley by thermoelectrics expert Matthew L. Scullin and Peidong Yang. The company uses nanotechnology and materials science applications to create thermoelectric generators that are more cost effective than previous bismuth telluride-based devices. The company is based in Hayward, California. It started with a license to use silicon nanowire developed at Lawrence Berkeley National Laboratory. They moved from UC Berkeley to offices in San Francisco in 2011, and later to Hayward.

An exhaust heat recovery system turns waste heat energy in exhaust gases into electric energy for batteries or mechanical energy reintroduced on the crankshaft. The technology is of increasing interest as car and heavy-duty vehicle manufacturers continue to increase efficiency, saving fuel and reducing emissions.

Gentherm Incorporated, formerly called Amerigon, is an American thermal management technologies company. Gentherm created the first thermoelectrically heated and cooled seat system for the automotive industry. Called the "Climate Control Seat" system, it was first adopted by the Ford Motor Company and introduced as an option on the model year 2000 Lincoln Navigator in 1999. Today it is available on more than 50 vehicles sold by Ford, General Motors, Toyota (Lexus), Kia, Hyundai, Nissan (Infinity), Range Rover and Jaguar Land Rover.

An internal combustion engine is a heat engine in which the combustion of a fuel occurs with an oxidizer in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine, the expansion of the high-temperature and high-pressure gases produced by combustion applies direct force to some component of the engine. The force is typically applied to pistons, turbine blades, a rotor, or a nozzle. This force moves the component over a distance, transforming chemical energy into kinetic energy which is used to propel, move or power whatever the engine is attached to.

In electrochemistry, a thermogalvanic cell is a kind of galvanic cell in which heat is employed to provide electrical power directly. These cells are electrochemical cells in which the two electrodes are deliberately maintained at different temperatures. This temperature difference generates a potential difference between the electrodes. The electrodes can be of identical composition and the electrolyte solution homogeneous. This is usually the case in these cells. This is in contrast to galvanic cells in which electrodes and/or solutions of different composition provide the electromotive potential. As long as there is a difference in temperature between the electrodes a current will flow through the circuit. A thermogalvanic cell can be seen as analogous to a concentration cell but instead of running on differences in the concentration/pressure of the reactants they make use of differences in the "concentrations" of thermal energy. The principal application of thermogalvanic cells is the production of electricity from low-temperature heat sources. Their energetic efficiency is low, in the range of 0.1% to 1% for conversion of heat into electricity.