A compressed-air car is a compressed-air vehicle powered by pressure vessels filled with compressed air. It is propelled by the release and expansion of the air within a motor adapted to compressed air. The car might be powered solely by air, or combined with other fuels such as gasoline, diesel, or an electric plant with regenerative braking.

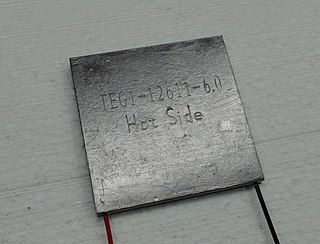

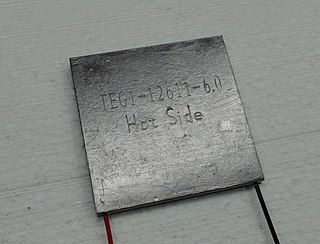

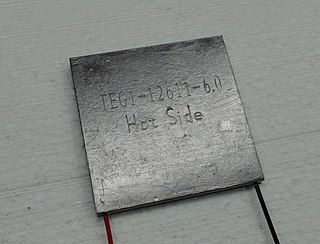

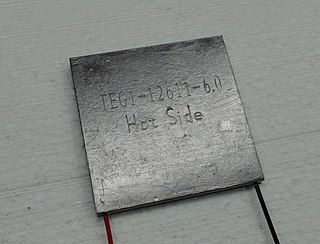

Thermoelectric cooling uses the Peltier effect to create a heat flux at the junction of two different types of materials. A Peltier cooler, heater, or thermoelectric heat pump is a solid-state active heat pump which transfers heat from one side of the device to the other, with consumption of electrical energy, depending on the direction of the current. Such an instrument is also called a Peltier device, Peltier heat pump, solid state refrigerator, or thermoelectric cooler (TEC) and occasionally a thermoelectric battery. It can be used either for heating or for cooling, although in practice the main application is cooling. It can also be used as a temperature controller that either heats or cools.

Cogeneration or combined heat and power (CHP) is the use of a heat engine or power station to generate electricity and useful heat at the same time.

A compressed-air vehicle (CAV) is a transport mechanism fueled by tanks of pressurized atmospheric gas and propelled by the release and expansion of the gas within a pneumatic motor.

Hybrid Synergy Drive (HSD), also known as Toyota Hybrid System II, is the brand name of Toyota Motor Corporation for the hybrid car drive train technology used in vehicles with the Toyota and Lexus marques. First introduced on the Prius, the technology is an option on several other Toyota and Lexus vehicles and has been adapted for the electric drive system of the hydrogen-powered Mirai, and for a plug-in hybrid version of the Prius. Previously, Toyota also licensed its HSD technology to Nissan for use in its Nissan Altima Hybrid. Its parts supplier Aisin offers similar hybrid transmissions to other car companies.

Capstone Green Energy, formerly Capstone Turbine Corporation, was incorporated in 1988 as a California based gas turbine manufacturer that specializes in microturbine power along with heating and cooling cogeneration systems. Key to the Capstone design is its use of air bearings, which provides maintenance and fluid-free operation for the lifetime of the turbine and reduces the system to a single moving part. This also eliminates the need for any cooling or other secondary systems. The Capstone microturbine is a versatile and dispatchable technology that is fuel flexible and scalable enough to fit a variety of applications.

A microturbine (MT) is a small gas turbine with similar cycles and components to a heavy gas turbine. The MT power-to-weight ratio is better than a heavy gas turbine because the reduction of turbine diameters causes an increase in shaft rotational speed. Heavy gas turbine generators are too large and too expensive for distributed power applications, so MTs are developed for small-scale power like electrical power generation alone or as combined cooling, heating, and power (CCHP) systems. The MT are 25 to 500 kW (34 to 671 hp) gas turbines evolved from piston engine turbochargers, aircraft auxiliary power units (APU) or small jet engines, the size of a refrigerator. Early turbines of 30–70 kW (40–94 hp) grew to 200–250 kW (270–340 hp).

A thermal power station is a type of power station in which heat energy is converted to electrical energy. In a steam-generating cycle heat is used to boil water in a large pressure vessel to produce high-pressure steam, which drives a steam turbine connected to an electrical generator. The low-pressure exhaust from the turbine enters a steam condenser where it is cooled to produce hot condensate which is recycled to the heating process to generate more high pressure steam. This is known as a Rankine cycle.

Waste heat is heat that is produced by a machine, or other process that uses energy, as a byproduct of doing work. All such processes give off some waste heat as a fundamental result of the laws of thermodynamics. Waste heat has lower utility than the original energy source. Sources of waste heat include all manner of human activities, natural systems, and all organisms, for example, incandescent light bulbs get hot, a refrigerator warms the room air, a building gets hot during peak hours, an internal combustion engine generates high-temperature exhaust gases, and electronic components get warm when in operation.

Energy recovery includes any technique or method of minimizing the input of energy to an overall system by the exchange of energy from one sub-system of the overall system with another. The energy can be in any form in either subsystem, but most energy recovery systems exchange thermal energy in either sensible or latent form.

A thermoelectric generator (TEG), also called a Seebeck generator, is a solid state device that converts heat directly into electrical energy through a phenomenon called the Seebeck effect. Thermoelectric generators function like heat engines, but are less bulky and have no moving parts. However, TEGs are typically more expensive and less efficient. When the same principle is used in reverse to create a heat gradient from an electric current, it is called a thermoelectric cooler.

An automotive thermoelectric generator (ATEG) is a device that converts some of the waste heat of an internal combustion engine (IC) into electricity using the Seebeck Effect. A typical ATEG consists of four main elements: A hot-side heat exchanger, a cold-side heat exchanger, thermoelectric materials, and a compression assembly system. ATEGs can convert waste heat from an engine's coolant or exhaust into electricity. By reclaiming this otherwise lost energy, ATEGs decrease fuel consumed by the electric generator load on the engine. However, the cost of the unit and the extra fuel consumed due to its weight must be also considered.

A waste heat recovery unit (WHRU) is an energy recovery heat exchanger that transfers heat from process outputs at high temperature to another part of the process for some purpose, usually increased efficiency. The WHRU is a tool involved in cogeneration. Waste heat may be extracted from sources such as hot flue gases from a diesel generator, steam from cooling towers, or even waste water from cooling processes such as in steel cooling.

A liquid nitrogen engine is powered by liquid nitrogen, which is stored in a tank. Traditional nitrogen engine designs work by heating the liquid nitrogen in a heat exchanger, extracting heat from the ambient air and using the resulting pressurized gas to operate a piston or rotary motor. Vehicles propelled by liquid nitrogen have been demonstrated, but are not used commercially. One such vehicle, Liquid Air, was demonstrated in 1902.

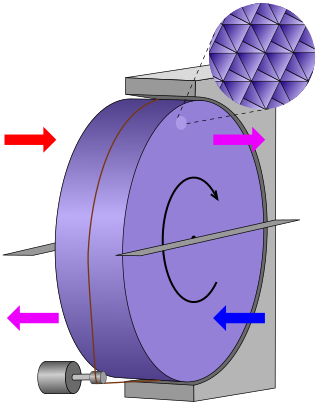

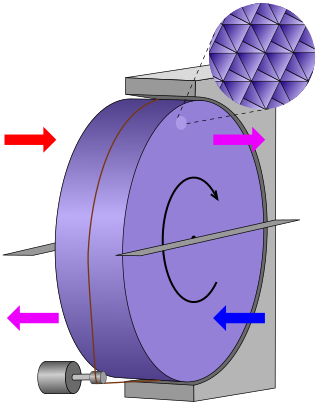

A thermal wheel, also known as a rotary heat exchanger, or rotary air-to-air enthalpy wheel, energy recovery wheel, or heat recovery wheel, is a type of energy recovery heat exchanger positioned within the supply and exhaust air streams of air-handling units or rooftop units or in the exhaust gases of an industrial process, in order to recover the heat energy. Other variants include enthalpy wheels and desiccant wheels. A cooling-specific thermal wheel is sometimes referred to as a Kyoto wheel.

Applications of the Stirling engine range from mechanical propulsion to heating and cooling to electrical generation systems. A Stirling engine is a heat engine operating by cyclic compression and expansion of air or other gas, the "working fluid", at different temperature levels such that there is a net conversion of heat to mechanical work. The Stirling cycle heat engine can also be driven in reverse, using a mechanical energy input to drive heat transfer in a reversed direction.

Alphabet Energy was a startup company founded in 2009 at the University of California, Berkeley by thermoelectrics expert Matthew L. Scullin and Peidong Yang. The company uses nanotechnology and materials science applications to create thermoelectric generators that are more cost effective than previous bismuth telluride-based devices. The company is based in Hayward, California. It started with a license to use silicon nanowire developed at Lawrence Berkeley National Laboratory. They moved from UC Berkeley to offices in San Francisco in 2011, and later to Hayward.

An exhaust heat recovery system turns waste heat energy in exhaust gases into electric energy for batteries or mechanical energy reintroduced on the crankshaft. The technology is of increasing interest as car and heavy-duty vehicle manufacturers continue to increase efficiency, saving fuel and reducing emissions.

An internal combustion engine is a heat engine in which the combustion of a fuel occurs with an oxidizer in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine, the expansion of the high-temperature and high-pressure gases produced by combustion applies direct force to some component of the engine. The force is typically applied to pistons, turbine blades, a rotor, or a nozzle. This force moves the component over a distance, transforming chemical energy into kinetic energy which is used to propel, move or power whatever the engine is attached to.

Immersion cooling is an IT cooling practice by which complete servers are immersed in a dielectric, electrically non-conductive fluid that has significantly higher thermal conductivity than air. Heat is removed from a system by putting the coolant in direct contact with hot components, and circulating the heated liquid through heat exchangers. This practice is highly effective because liquid coolants can absorb more heat from the system, and are more easily circulated through the system, than air. Immersion cooling has many benefits, including but not limited to: sustainability, performance, reliability and cost