A dye is a colored substance that chemically bonds to the substrate to which it is being applied. This distinguishes dyes from pigments which do not chemically bind to the material they color. Dye is generally applied in an aqueous solution, and may require a mordant to improve the fastness of the dye on the fiber.

Nylon is a generic designation for a family of synthetic polymers composed of polyamides. Nylon is a silk-like thermoplastic, generally made from petroleum, that can be melt-processed into fibers, films, or shapes. Nylon polymers can be mixed with a wide variety of additives to achieve many different property variations. Nylon polymers have found significant commercial applications in fabric and fibers, in shapes, and in films.

Aramid fibers, short for aromatic polyamide, are a class of heat-resistant and strong synthetic fibers. They are used in aerospace and military applications, for ballistic-rated body armor fabric and ballistic composites, in marine cordage, marine hull reinforcement, and as an asbestos substitute.

Microfiber is synthetic fiber finer than one denier or decitex/thread, having a diameter of less than ten micrometers. A strand of silk is about one denier and about a fifth of the diameter of a human hair.

Tie-dye is a term used to describe a number of resist dyeing techniques and the resulting dyed products of these processes. The process of tie-dye typically consists of folding, twisting, pleating, or crumpling fabric or a garment, before binding with string or rubber bands, followed by the application of dye or dyes. The manipulations of the fabric before the application of dye are called resists, as they partially or completely prevent ('resist') the applied dye from coloring the fabric. More sophisticated tie-dye may involve additional steps, including an initial application of dye before the resist, multiple sequential dyeing and resist steps, and the use of other types of resists and discharge.

Tannic acid is a specific form of tannin, a type of polyphenol. Its weak acidity (pKa around 6) is due to the numerous phenol groups in the structure. The chemical formula for commercial tannic acid is often given as C76H52O46, which corresponds with decagalloyl glucose, but in fact it is a mixture of polygalloyl glucoses or polygalloyl quinic acid esters with the number of galloyl moieties per molecule ranging from 2 up to 12 depending on the plant source used to extract the tannic acid. Commercial tannic acid is usually extracted from any of the following plant parts: Tara pods (Caesalpinia spinosa), gallnuts from Rhus semialata or Quercus infectoria or Sicilian sumac leaves (Rhus coriaria).

Dyeing is the application of dyes or pigments on textile materials such as fibers, yarns, and fabrics with the goal of achieving color with desired color fastness. Dyeing is normally done in a special solution containing dyes and particular chemical material. Dye molecules are fixed to the fiber by absorption, diffusion, or bonding with temperature and time being key controlling factors. The bond between dye molecule and fiber may be strong or weak, depending on the dye used. Dyeing and printing are different applications; in printing, color is applied to a localized area with desired patterns. In dyeing, it is applied to the entire textile.

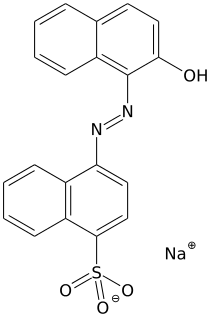

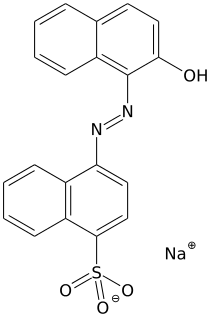

Acid dyes are anionic, soluble in water and are essentially applied from acidic bath. These dyes possess acidic groups, such as SO3H and COOH and are applied on wool, silk and nylon when ionic bond is established between protonated –NH2 group of fibre and acid group of dye. Overall wash fastness is poor although lightfastness is quite good. As dye and fibre contain opposite electrical nature, strike rate and uptake of acid dye on these fibres is faster; electrolyte at higher concentration is added to retard dye uptake and to form levelled shades. Acid generates cation on fibre and temperature helps to substitute negative part of acid with anionic dye molecules.

Nylon 6 or polycaprolactam is a polymer developed by Paul Schlack at IG Farben to reproduce the properties of nylon 6,6 without violating the patent on its production. It is a semicrystalline polyamide. Unlike most other nylons, nylon 6 is not a condensation polymer, but instead is formed by ring-opening polymerization; this makes it a special case in the comparison between condensation and addition polymers. Its competition with nylon 6,6 and the example it set have also shaped the economics of the synthetic fibre industry. It is sold under numerous trade names including Perlon (Germany), Dederon, Nylatron, Capron, Ultramid, Akulon, Kapron, Rugopa (Turkey) and Durethan.

Vat dyes are a class of dyes that are classified as such because of the method by which they are applied. Vat dyeing is a process that refers to dyeing that takes place in a bucket or vat. The original vat dye is indigo, once obtained only from plants but now often produced synthetically.

Polyester is a category of polymers that contain the ester functional group in every repeat unit of their main chain. As a specific material, it most commonly refers to a type called polyethylene terephthalate (PET). Polyesters include naturally occurring chemicals, such as in plants and insects, as well as synthetics such as polybutyrate. Natural polyesters and a few synthetic ones are biodegradable, but most synthetic polyesters are not. Synthetic polyesters are used extensively in clothing.

Disperse Red 11, or 1,4-diamino-2-methoxyanthraquinone, is a red disperse dye derived from anthraquinone.

In textile manufacturing, finishing refers to the processes that convert the woven or knitted cloth into a usable material and more specifically to any process performed after dyeing the yarn or fabric to improve the look, performance, or "hand" (feel) of the finish textile or clothing. The precise meaning depends on context.

Disperse dye is a category of synthetic dye intended for polyester and related hydrophobic fibers. Disperse dyes are polar molecules containing anthraquinone or azo groups. It is estimated that 85% of disperse dyes are azos or anthraquinone dyes.

Methine dyes are dyes whose chromophoric system consists of conjugated double bonds (polyenes) flanked by two end groups: an electron acceptor A and an electron donor D.

Structural of methine dyes

Wet process engineering is one of the major streams in textile engineering which refers to the engineering of textile chemical processes and associated applied science. The other three streams in textile engineering are yarn engineering, fabric engineering, and apparel engineering. The processes of this stream are involved or carried out in an aqueous stage. Hence, it is called a wet process which usually covers pre-treatment, dyeing, printing, and finishing.

o-Cresolphthalein is a phthalein dye used as a pH indicator in titrations. It is insoluble in water but soluble in ethanol. Its solution is colourless below pH 8.2, and purple above 9.8. Its molecular formula is C22H18O4. It is used medically to determine calcium levels in the human body, or to synthesize polyamides or polyimides.

Fabric treatments are processes that make fabric softer, or water resistant, or enhance dye penetration after they are woven. Fabric treatments get applied when the textile itself cannot add other properties. Treatments include, scrim, foam lamination, fabric protector or stain repellent, anti microbial and flame retardant.

Disperse Yellow 42, or 4-anilino-3-nitrobenzenesulfonanilide, is a disperse dye that is primarily used to dye polyester fibers. It is prepared by the reaction of two equivalents of aniline with 4-chloro-3-nitrobenzenesulfonyl chloride. An estimated 10,000 tons were prepared in 1990, making Disperse Yellow 42 the nitro dye produced on the largest scale.

Deweighting, deweighing or weight reduction, is a chemical treatment that peels the surface of polyester fibers and makes them softer and finer. It also reduces the fiber weight and hence weakens the strength. Additionally, the treatment enhances the absorbency of the treated substrates. Deweighting is an alkaline hydrolysis treatment that affects the surface fibers of the polyester and reduces the decitex or denier of fibers, weight loss of between 10% and 30% is possible during the treatment. Polyester and cotton blends can be treated with an alkali process to make them look and feel like silk.