This article has multiple issues. Please help improve it or discuss these issues on the talk page . (Learn how and when to remove these messages)

|

| |

| Manufacturer | Honeywell |

|---|---|

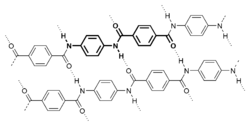

Gold Flex is a non-woven fabric manufactured by Honeywell from Kevlar, and is often used in ballistic vests and body armor. Gold Flex is lighter than woven Kevlar, Twaron and other Ballistic material. Gold Flex is a laminated material consisting of cross-laid, non-woven fibers in a resin matrix. The fibers are laid straight and not in a woven fabric configuration. When an object strikes this material, a "web" of its clusters absorb the impact and minimizes penetration.

Contents

Honeywell describes "Gold Shield" as being almost identical, only either using two plies instead of four, or using a different resin, depending on version. [1] Both products use Honeywell's patented "Shield" technology, which is present in their Spectra Shield.