The guitar is a stringed musical instrument that is usually fretted and typically has six or twelve strings. It is usually held flat against the player's body and played by strumming or plucking the strings with the dominant hand, while simultaneously pressing selected strings against frets with the fingers of the opposite hand. A guitar pick may also be used to strike the strings. The sound of the guitar is projected either acoustically, by means of a resonant hollow chamber on the guitar, or amplified by an electronic pickup and an amplifier.

An arrow is a fin-stabilized projectile launched by a bow. A typical arrow usually consists of a long, stiff, straight shaft with a weighty arrowhead attached to the front end, multiple fin-like stabilizers called fletchings mounted near the rear, and a slot at the rear end called a nock for engaging the bowstring. A container or bag carrying additional arrows for convenient reloading is called a quiver.

A blacksmith is a metalsmith who creates objects primarily from wrought iron or steel, but sometimes from other metals, by forging the metal, using tools to hammer, bend, and cut. Blacksmiths produce objects such as gates, grilles, railings, light fixtures, furniture, sculpture, tools, agricultural implements, decorative and religious items, cooking utensils, and weapons. There was a historical distinction between the heavy work of the blacksmith and the more delicate operations of a whitesmith, who usually worked in gold, silver, pewter, or the finishing steps of fine steel. The place where a blacksmith works is variously called a smithy, a forge, or a blacksmith's shop.

Differential heat treatment is a technique used during heat treating of steel to harden or soften certain areas of an object, creating a difference in hardness between these areas. There are many techniques for creating a difference in properties, but most can be defined as either differential hardening or differential tempering. These were common heat treatment techniques used historically in Europe and Asia, with possibly the most widely known example being from Japanese swordsmithing. Some modern varieties were developed in the twentieth century as metallurgical knowledge and technology rapidly increased.

Cookware and bakeware is food preparation equipment, such as cooking pots, pans, baking sheets etc. used in kitchens. Cookware is used on a stove or range cooktop, while bakeware is used in an oven. Some utensils are considered both cookware and bakeware.

The fingerboard is an important component of most stringed instruments. It is a thin, long strip of material, usually wood, that is laminated to the front of the neck of an instrument. The strings run over the fingerboard, between the nut and bridge. To play the instrument, a musician presses strings down to the fingerboard to change the vibrating length, changing the pitch. This is called stopping the strings. Depending on the instrument and the style of music, the musician may pluck, strum or bow one or more strings with the hand that is not fretting the notes. On some instruments, notes can be sounded by the fretting hand alone, such as with hammer ons, an electric guitar technique.

Boat building is the design and construction of boats — and their on-board systems. This includes at minimum the construction of a hull, with any necessary propulsion, mechanical, navigation, safety and other service systems as the craft requires.

A card scraper or cabinet scraper is a woodworking shaping and finishing tool. It is used to manually remove small amounts of material and excels in tricky grain areas where hand planes would cause tear out. Card scrapers are most suitable for working with hardwoods, and can be used instead of sandpaper. Scraping produces a cleaner surface than sanding; it does not clog the pores of the wood with dust, and does not leave a fuzz of torn fibers.

Formwork is molds into which concrete or similar materials are either precast or cast-in-place. In the context of concrete construction, the falsework supports the shuttering molds. In specialty applications formwork may be permanently incorporated into the final structure, adding insulation or helping reinforce the finished structure.

A foundry is a factory that produces metal castings. Metals are cast into shapes by melting them into a liquid, pouring the metal into a mold, and removing the mold material after the metal has solidified as it cools. The most common metals processed are aluminum and cast iron. However, other metals, such as bronze, brass, steel, magnesium, and zinc, are also used to produce castings in foundries. In this process, parts of desired shapes and sizes can be formed.

Continuous casting, also called strand casting, is the process whereby molten metal is solidified into a "semifinished" billet, bloom, or slab for subsequent rolling in the finishing mills. Prior to the introduction of continuous casting in the 1950s, steel was poured into stationary molds to form ingots. Since then, "continuous casting" has evolved to achieve improved yield, quality, productivity and cost efficiency. It allows lower-cost production of metal sections with better quality, due to the inherently lower costs of continuous, standardised production of a product, as well as providing increased control over the process through automation. This process is used most frequently to cast steel. Aluminium and copper are also continuously cast.

A violin consists of a body or corpus, a neck, a finger board, a bridge, a soundpost, four strings, and various fittings. The fittings are the tuning pegs, tailpiece and tailgut, endpin, possibly one or more fine tuners on the tailpiece, and in the modern style of playing, usually a chinrest, either attached with the cup directly over the tailpiece or to the left of it. There are many variations of chinrests: center-mount types such as Flesch or Guarneri, clamped to the body on both sides of the tailpiece, and side-mount types clamped to the lower bout to the left of the tailpiece.

The neck is the part of certain string instruments that projects from the main body and is the base of the fingerboard, where the fingers are placed to stop the strings at different pitches. Guitars, banjos, ukuleles, lutes, the violin family, and the mandolin family are examples of instruments which have necks. Necks are also an integral part of certain woodwind instruments, such as the saxophone.

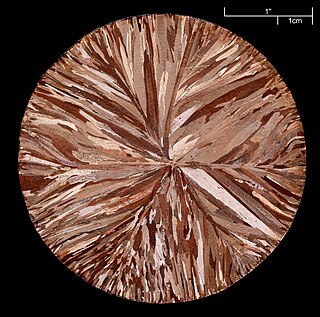

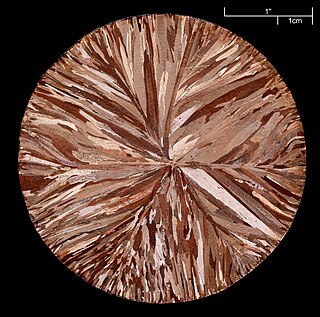

Tonewood refers to specific wood varieties used for woodwind or acoustic stringed instruments. The word implies that certain species exhibit qualities that enhance acoustic properties of the instruments, but other properties of the wood such as aesthetics and availability have always been considered in the selection of wood for musical instruments. According to Mottola's Cyclopedic Dictionary of Lutherie Terms, tonewood is:

Wood that is used to make stringed musical instruments. The term is often used to indicate wood species that are suitable for stringed musical instruments and, by exclusion, those that are not. But the list of species generally considered to be tonewoods changes constantly and has changed constantly throughout history.

This glossary of woodworking lists a number of specialized terms and concepts used in woodworking, carpentry, and related disciplines.

Japanese swordsmithing is the labour-intensive bladesmithing process developed in Japan beginning in the sixth century for forging traditionally made bladed weapons (nihonto) including katana, wakizashi, tantō, yari, naginata, nagamaki, tachi, nodachi, ōdachi, kodachi, and ya (arrow).

Leather crafting or simply leathercraft is the practice of making leather into craft objects or works of art, using shaping techniques, coloring techniques or both.

Tube bending is any metal forming processes used to permanently form pipes or tubing. Tube bending may be form-bound or use freeform-bending procedures, and it may use heat supported or cold forming procedures.

Steam bending is a woodworking technique where wood is exposed to steam to make it pliable. Heat and moisture from steam can soften wood fibres enough so they can be bent and stretched, and when cooled down they will hold their new shape.

A fillet knife is a kitchen knife used for filleting. It gives good control and aids in filleting. It is a very flexible member of the boning knife family that is used to filet and prepare fish. Fillet knife blades are typically 15 to 28 cm long. This allows them to move easily along the backbone and under the skin of meat.