Joinery is a part of woodworking that involves joining pieces of wood, engineered lumber, or synthetic substitutes, to produce more complex items. Some woodworking joints employ mechanical fasteners, bindings, or adhesives, while others use only wood elements.

The First Dynasty of ancient Egypt covers the first series of Egyptian kings to rule over a unified Egypt. It immediately follows the unification of Upper and Lower Egypt, possibly by Narmer, and marks the beginning of the Early Dynastic Period, when power was centered at Thinis.

A lap joint or overlap joint is a joint in which the members overlap. Lap joints can be used to join wood, plastic, or metal. A lap joint can be used in woodworking for joining wood together.

A dovetail joint or simply dovetail is a joinery technique most commonly used in woodworking joinery (carpentry), including furniture, cabinets, log buildings, and traditional timber framing. Noted for its resistance to being pulled apart, also known as tensile strength, the dovetail joint is commonly used to join the sides of a drawer to the front. A series of pins cut to extend from the end of one board interlock with a series of 'tails' cut into the end of another board. The pins and tails have a trapezoidal shape. Once glued, a wooden dovetail joint requires no mechanical fasteners.

The Japanese saw or nokogiri (鋸) is a type of saw used in woodworking and Japanese carpentry that cuts on the pull stroke, unlike most European saws that cut on the push stroke. Japanese saws are the best known pull saws, but they are also used in China, Iran, Iraq, Korea, Nepal, and Turkey. Among European saws, both coping saws for woodworking and jeweler's saws for metal working also cut on the pull stroke like Japanese saws. Cutting on the pull stroke is claimed to cut more efficiently and leave a narrower cut width. On the other hand, a pull stroke does not easily permit putting one's body weight behind a stroke. This can be readily solved by using a vice or clamping. Another disadvantage, due to the arrangement and form of the teeth, is that Japanese saws do not work as well on hardwoods as European saws do. Japanese saws were originally intended for comparatively soft woods like cypress and pine whereas European saws were intended for hard woods like oak and maple.

A joist is a horizontal structural member used in framing to span an open space, often between beams that subsequently transfer loads to vertical members. When incorporated into a floor framing system, joists serve to provide stiffness to the subfloor sheathing, allowing it to function as a horizontal diaphragm. Joists are often doubled or tripled, placed side by side, where conditions warrant, such as where wall partitions require support.

A log house, or log building, is a structure built with horizontal logs interlocked at the corners by notching. Logs may be round, squared or hewn to other shapes, either handcrafted or milled. The term "log cabin" generally refers to a smaller, more rustic log house, such as a hunting cabin in the woods, that may or may not have electricity or plumbing.

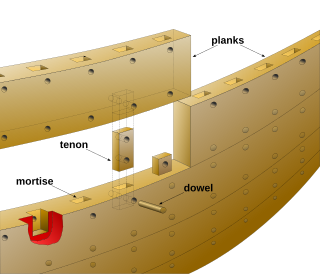

A treenail, also trenail, trennel, or trunnel, is a wooden peg, pin, or dowel used to fasten pieces of wood together, especially in timber frames, covered bridges, wooden shipbuilding and boat building. It is driven into a hole bored through two pieces of structural wood.

A mortiser or morticer is a specialized woodworking machine used to cut square or rectangular holes in a piece of lumber (timber), such as a mortise in a mortise and tenon joint.

Pocket-hole joinery, or pocket-screw joinery, involves drilling a hole at an angle — usually 15 degrees — into one work piece, and then joining it to a second work piece with a self-tapping screw.

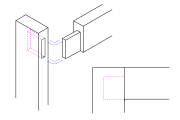

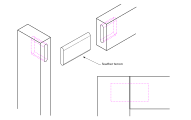

A bridle joint is a woodworking joint, similar to a mortise and tenon, in that a tenon is cut on the end of one member and a mortise is cut into the other to accept it. The distinguishing feature is that the tenon and the mortise are cut to the full width of the tenon member.

This glossary of woodworking lists a number of specialized terms and concepts used in woodworking, carpentry, and related disciplines.

Ancient Chinese wooden architecture is a style of Chinese architecture. In the West it has been studied less than other architectural styles. Although Chinese architectural history reaches far back in time, descriptions of Chinese architecture are often confined to the well known Forbidden City with little else explored by the West. Although common features of Chinese architecture have been unified into a vocabulary illustrating uniquely Chinese forms and methods, until recently data has not been available. Because of the lack of knowledge of the roots of Chinese architecture, the descriptions of its elements are often translated into Western terms and architectural theory, losing their unique Chinese meanings. A cause of this deficiency is that the two most important Chinese government architecture manuals, the Song dynasty Yingzao Fashi and Qing Architecture Standards have never been translated into any Western language.

The method of building wooden buildings with a traditional timber frame with horizontal plank or log infill has many names, the most common of which are piece sur piece, corner post construction, post-and-plank, Ständerbohlenbau (German) and skiftesverk (Swedish). This traditional building method is believed to be the predecessor to half-timber construction widely known by its German name fachwerkbau which has wall infill of wattle and daub, brick, or stone. This carpentry was used from parts of Scandinavia to Switzerland to western Russia. Though relatively rare now, two types are found in a number of regions in North America, more common are the walls with planks or timbers which slide in a groove in the posts and less common is a type where horizontal logs are tenoned into individual mortises in the posts. This method is not the same as the plank-frame buildings in North America with vertical plank walls.

Ancient boat building methods can be categorized as one of hide, log, sewn, lashed-plank, clinker, shell-first, and frame-first. While the frame-first technique dominates the modern ship construction industry, the ancients relied primarily on the other techniques to build their watercraft. In many cases, these techniques were very labor-intensive and/or inefficient in their use of raw materials. Regardless of differences in ship construction techniques, the vessels of the ancient world, particularly those that plied the waters of the Mediterranean Sea and the islands of Southeast Asia were seaworthy craft, capable of allowing people to engage in large-scale maritime trade.

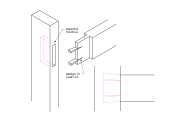

Hammer-headed tenon joints are one method that can be used to join curved members of joinery components.

The Abydos boats are the remnants of a group of ancient royal Egyptian ceremonial boats found at an archaeological site in Abydos, Egypt. Discovered in 1991, excavation of the Abydos boats began in 2000 at which time fourteen boats were identified. They are located alongside the massive mudbrick structure known as Shunet El Zebib, attributed to the 2nd Dynasty Pharaoh Khasekhemwy. Shunet El Zebib is one of several such "enclosure wall" constructions at this site dating back to the 1st Dynasty, and is located nearly one mile from the early dynastic royal cemetery of Umm El Qa'ab.

The Ma'agan Michael Ship is a well-preserved 5th-century BCE boat discovered off the coast of Kibbutz Ma'agan Michael, Israel, in 1985. The ship was excavated and its timber immersed in preservation tanks at the University of Haifa, undergoing a seven-year process of impregnation by heated polyethylene glycol (PEG). In March 1999, the boat was reassembled and transferred to a dedicated wing built at the Hecht Museum, on the grounds of the university. The boat has provided researchers with insights into ancient methods of shipbuilding and the evolution of anchors.

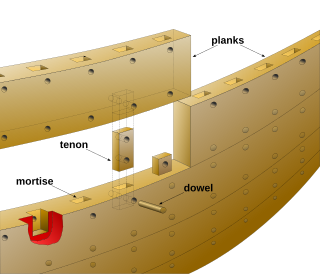

Phoenician joints is a locked mortise and tenon wood joinery technique used in shipbuilding to fasten watercraft hulls. The locked mortise and tenon technique consists of cutting a mortise, or socket, into the edges of two planks and fastening them together with a rectangular wooden knob. The assembly is then locked in place by driving a dowel through one or more holes drilled through the mortise side wall and tenon.