An alloy is a mixture of chemical elements of which at least one is a metal. Unlike chemical compounds with metallic bases, an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductility, opacity, and luster, but may have properties that differ from those of the pure metals, such as increased strength or hardness. In some cases, an alloy may reduce the overall cost of the material while preserving important properties. In other cases, the mixture imparts synergistic properties to the constituent metal elements such as corrosion resistance or mechanical strength.

Heat treating is a group of industrial, thermal and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also used in the manufacture of many other materials, such as glass. Heat treatment involves the use of heating or chilling, normally to extreme temperatures, to achieve the desired result such as hardening or softening of a material. Heat treatment techniques include annealing, case hardening, precipitation strengthening, tempering, carburizing, normalizing and quenching. Although the term heat treatment applies only to processes where the heating and cooling are done for the specific purpose of altering properties intentionally, heating and cooling often occur incidentally during other manufacturing processes such as hot forming or welding.

Austenite, also known as gamma-phase iron (γ-Fe), is a metallic, non-magnetic allotrope of iron or a solid solution of iron with an alloying element. In plain-carbon steel, austenite exists above the critical eutectoid temperature of 1000 K (727 °C); other alloys of steel have different eutectoid temperatures. The austenite allotrope is named after Sir William Chandler Roberts-Austen (1843–1902). It exists at room temperature in some stainless steels due to the presence of nickel stabilizing the austenite at lower temperatures.

High-strength low-alloy steel (HSLA) is a type of alloy steel that provides better mechanical properties or greater resistance to corrosion than carbon steel. HSLA steels vary from other steels in that they are not made to meet a specific chemical composition but rather specific mechanical properties. They have a carbon content between 0.05 and 0.25% to retain formability and weldability. Other alloying elements include up to 2.0% manganese and small quantities of copper, nickel, niobium, nitrogen, vanadium, chromium, molybdenum, titanium, calcium, rare-earth elements, or zirconium. Copper, titanium, vanadium, and niobium are added for strengthening purposes. These elements are intended to alter the microstructure of carbon steels, which is usually a ferrite-pearlite aggregate, to produce a very fine dispersion of alloy carbides in an almost pure ferrite matrix. This eliminates the toughness-reducing effect of a pearlitic volume fraction yet maintains and increases the material's strength by refining the grain size, which in the case of ferrite increases yield strength by 50% for every halving of the mean grain diameter. Precipitation strengthening plays a minor role, too. Their yield strengths can be anywhere between 250–590 megapascals (36,000–86,000 psi). Because of their higher strength and toughness HSLA steels usually require 25 to 30% more power to form, as compared to carbon steels.

In materials science, creep is the tendency of a solid material to undergo slow deformation while subject to persistent mechanical stresses. It can occur as a result of long-term exposure to high levels of stress that are still below the yield strength of the material. Creep is more severe in materials that are subjected to heat for long periods and generally increase as they near their melting point.

Maraging steels are steels that are known for possessing superior strength and toughness without losing ductility. Aging refers to the extended heat-treatment process. These steels are a special class of very-low-carbon ultra-high-strength steels that derive their strength not from carbon, but from precipitation of intermetallic compounds. The principal alloying element is 15 to 25 wt% nickel. Secondary alloying elements, which include cobalt, molybdenum and titanium, are added to produce intermetallic precipitates. Original development was carried out on 20 and 25 wt% Ni steels to which small additions of aluminium, titanium, and niobium were made; a rise in the price of cobalt in the late 1970s led to the development of cobalt-free maraging steels.

Precipitation hardening, also called age hardening or particle hardening, is a heat treatment technique used to increase the yield strength of malleable materials, including most structural alloys of aluminium, magnesium, nickel, titanium, and some steels, stainless steels, and duplex stainless steel. In superalloys, it is known to cause yield strength anomaly providing excellent high-temperature strength.

A superalloy, or high-performance alloy, is an alloy with the ability to operate at a high fraction of its melting point. Key characteristics of a superalloy include mechanical strength, thermal creep deformation resistance, surface stability, and corrosion and oxidation resistance.

Hardening is a metallurgical metalworking process used to increase the hardness of a metal. The hardness of a metal is directly proportional to the uniaxial yield stress at the location of the imposed strain. A harder metal will have a higher resistance to plastic deformation than a less hard metal.

The SAE steel grades system is a standard alloy numbering system for steel grades maintained by SAE International.

An aluminium alloy (UK/IUPAC) or aluminum alloy is an alloy in which aluminium (Al) is the predominant metal. The typical alloying elements are copper, magnesium, manganese, silicon, tin, nickel and zinc. There are two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories heat-treatable and non-heat-treatable. About 85% of aluminium is used for wrought products, for example rolled plate, foils and extrusions. Cast aluminium alloys yield cost-effective products due to the low melting point, although they generally have lower tensile strengths than wrought alloys. The most important cast aluminium alloy system is Al–Si, where the high levels of silicon (4–13%) contribute to give good casting characteristics. Aluminium alloys are widely used in engineering structures and components where light weight or corrosion resistance is required.

Boriding, also called boronizing, is the process by which boron is added to a metal or alloy. It is a type of surface hardening. In this process boron atoms are diffused into the surface of a metal component. The resulting surface contains metal borides, such as iron borides, nickel borides, and cobalt borides, As pure materials, these borides have extremely high hardness and wear resistance. Their favorable properties are manifested even when they are a small fraction of the bulk solid. Boronized metal parts are extremely wear resistant and will often last two to five times longer than components treated with conventional heat treatments such as hardening, carburizing, nitriding, nitrocarburizing or induction hardening. Most borided steel surfaces will have iron boride layer hardnesses ranging from 1200-1600 HV. Nickel-based superalloys such as Inconel and Hastalloys will typically have nickel boride layer hardnesses of 1700-2300 HV.

In metallurgy, solid solution strengthening is a type of alloying that can be used to improve the strength of a pure metal. The technique works by adding atoms of one element to the crystalline lattice of another element, forming a solid solution. The local nonuniformity in the lattice due to the alloying element makes plastic deformation more difficult by impeding dislocation motion through stress fields. In contrast, alloying beyond the solubility limit can form a second phase, leading to strengthening via other mechanisms.

Nickel aluminide refers to either of two widely used intermetallic compounds, Ni3Al or NiAl, but the term is sometimes used to refer to any nickel–aluminium alloy. These alloys are widely used because of their high strength even at high temperature, low density, corrosion resistance, and ease of production. Ni3Al is of specific interest as a precipitate in nickel-based superalloys, where it is called the γ' (gamma prime) phase. It gives these alloys high strength and creep resistance up to 0.7–0.8 of its melting temperature. Meanwhile, NiAl displays excellent properties such as lower density and higher melting temperature than those of Ni3Al, and good thermal conductivity and oxidation resistance. These properties make it attractive for special high-temperature applications like coatings on blades in gas turbines and jet engines. However, both these alloys have the disadvantage of being quite brittle at room temperature, with Ni3Al remaining brittle at high temperatures as well. To address this problem, has been shown that Ni3Al can be made ductile when manufactured in single-crystal form rather than in polycrystalline form.

Electron-beam additive manufacturing, or electron-beam melting (EBM) is a type of additive manufacturing, or 3D printing, for metal parts. The raw material is placed under a vacuum and fused together from heating by an electron beam. This technique is distinct from selective laser sintering as the raw material fuses have completely melted. Selective Electron Beam Melting (SEBM) emerged as a powder bed-based additive manufacturing (AM) technology and was brought to market in 1997 by Arcam AB Corporation headquartered in Sweden.

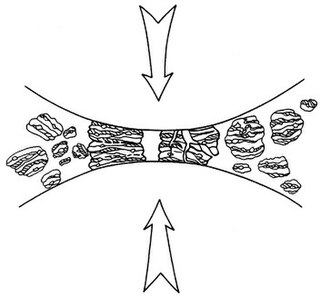

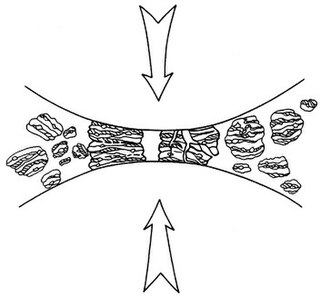

Mechanical alloying (MA) is a solid-state and powder processing technique involving repeated cold welding, fracturing, and re-welding of blended powder particles in a high-energy ball mill to produce a homogeneous material. Originally developed to produce oxide-dispersion strengthened (ODS) nickel- and iron-base superalloys for applications in the aerospace industry, MA has now been shown to be capable of synthesizing a variety of equilibrium and non-equilibrium alloy phases starting from blended elemental or pre-alloyed powders. The non-equilibrium phases synthesized include supersaturated solid solutions, metastable crystalline and quasicrystalline phases, nanostructures, and amorphous alloys.

Selective laser melting (SLM) is one of many proprietary names for a metal additive manufacturing (AM) technology that uses a bed of powder with a source of heat to create metal parts. Also known as direct metal laser sintering (DMLS), the ASTM standard term is powder bed fusion (PBF). PBF is a rapid prototyping, 3D printing, or additive manufacturing technique designed to use a high power-density laser to melt and fuse metallic powders together.

Inconel Alloy 625 is a nickel-based superalloy that possesses high strength properties and resistance to elevated temperatures. It also demonstrates remarkable protection against corrosion and oxidation. Its ability to withstand high stress and a wide range of temperatures, both in and out of water, as well as being able to resist corrosion while being exposed to highly acidic environments makes it a fitting choice for nuclear and marine applications.

Havar, or UNS R30004, is an alloy of cobalt, possessing a very high mechanical strength. It can be heat-treated. It is highly resistant to corrosion and is non-magnetic. It is biocompatible. It has high fatigue resistance. It is a precipitation hardening superalloy.

Aluminium–scandium alloys (AlSc) are aluminum alloys that consist largely of aluminium (Al) and traces of scandium (Sc) as the main alloying elements. In principle, aluminium alloys strengthened with additions of scandium are very similar to traditional nickel-base superalloys in that both are strengthened by coherent, coarsening resistant precipitates with an ordered L12 structure. But Al–Sc alloys contain a much lower volume fraction of precipitates, and the inter-precipitate distance is much smaller than in their nickel-base counterparts. In both cases however, the coarsening resistant precipitates allow the alloys to retain their strength at high temperatures.