A power station, also referred to as a power plant and sometimes generating station or generating plant, is an industrial facility for the generation of electric power. Power stations are generally connected to an electrical grid.

A combined cycle power plant is an assembly of heat engines that work in tandem from the same source of heat, converting it into mechanical energy. On land, when used to make electricity the most common type is called a combined cycle gas turbine (CCGT) plant. The same principle is also used for marine propulsion, where it is called a combined gas and steam (COGAS) plant. Combining two or more thermodynamic cycles improves overall efficiency, which reduces fuel costs.

Cogeneration or combined heat and power (CHP) is the use of a heat engine or power station to generate electricity and useful heat at the same time.

District heating is a system for distributing heat generated in a centralized location through a system of insulated pipes for residential and commercial heating requirements such as space heating and water heating. The heat is often obtained from a cogeneration plant burning fossil fuels or biomass, but heat-only boiler stations, geothermal heating, heat pumps and central solar heating are also used, as well as heat waste from nuclear power electricity generation. District heating plants can provide higher efficiencies and better pollution control than localized boilers. According to some research, district heating with combined heat and power (CHPDH) is the cheapest method of cutting carbon emissions, and has one of the lowest carbon footprints of all fossil generation plants.

A thermal power station is a power station in which heat energy is converted to electricity. Typically, fuel is used to boil water in a large pressure vessel to produce high-pressure steam, which drives a steam turbine connected to an electrical generator. The low-pressure exhaust from the turbine passes through a steam condenser and is recycled to where it was heated. This is known as a Rankine cycle. Natural gas can also be burnt directly in a gas turbine similarly connected to a generator.

Longannet power station was a large coal-fired power station in Fife, and the last coal-fired power station in Scotland. It was capable of co-firing biomass, natural gas and sludge. The station stood on the north bank of the Firth of Forth, near Kincardine on Forth.

The steam-electric power station is a power station in which the electric generator is steam driven. Water is heated, turns into steam and spins a steam turbine which drives an electrical generator. After it passes through the turbine, the steam is condensed in a condenser. The greatest variation in the design of steam-electric power plants is due to the different fuel sources.

Kirishi Power Station is a thermal power station (GRES) at the town of Kirishi, Kirishsky District, Leningrad Oblast, Russia. The power plant is located adjacent to a larger Kirishi oil refinery. Installed electrical capacity of the power station reached 2595 MW after completion of modernization program for unit 6 in 2011, which included installation of two gas turbines for this unit to utilize combined cycle with total increase of capacity 500 MW and efficiency 20%. The heating capacity is 1,234 Gcal/h.

Enel Russia is a Russian power generation company created by the reorganization of RAO UES, a former united power company of Russia. The company is registered in Yekaterinburg and its headquarters are in Moscow. The Italian Enel Group owns a majority stake of the company (56%).

Beryozovskaya GRES is a coal-fired power plant near the town of Sharypovo in Krasnoyarsk Krai, Russia. The power plant is owned by Unipro. The installed capacity of the plant is 1,600 megawatts (2,100,000 hp).

The Lukoml power station is a natural gas-fired thermal power station located in Novolukoml, Vitsebsk Voblast, Belarus. It is operated by Belenergo.

A waste heat recovery unit (WHRU) is an energy recovery heat exchanger that transfers heat from process outputs at high temperature to another part of the process for some purpose, usually increased efficiency. The WHRU is a tool involved in cogeneration. Waste heat may be extracted from sources such as hot flue gases from a diesel generator, steam from cooling towers, or even waste water from cooling processes such as in steel cooling.

The Avedøre Power Station is a combined heat and power station, located in Avedøre, Denmark, just south of Copenhagen, and is owned by Ørsted A/S. Avedøre Power Plant is a high-technology facility and one of the world's most efficient of its kind, being able to utilize as much as 94% of the energy in the fuel and convert 49% of the fuel energy into electricity. Apart from using coal, petroleum (oil) and natural gas, the plant runs on a wide variety of biomass fuels such as straw and wood pellets. The plant consists of two units with a total capacity of 793 MW of electricity and 918 MW of heat. The combination of producing electricity and heat for district heating at the same time is widely used in Denmark and the rest of Scandinavia, due to the need of domestic heating together with the Danish energy companies putting a big effort into optimising the energy plants.

The West Springfield Generating Station, also known by its corporate name EP Energy Massachusetts, LLC, is a fossil-fuel-fired power plant located in West Springfield, Massachusetts. The station is a "peaking" facility, meaning that it primarily operates during peak electrical demand. The facility consists of two 49-megawatt (MW) combustion turbine generators fueled by natural gas or ultra low-sulphur diesel fuel, one 18 MW jet turbine that is fueled by kerosene, and one 107 MW simple-cycle steam boiler unit burning no. 6 fuel oil, ULSD or natural gas. The station also has a small auxiliary boiler for process and building heat and an emergency back-up generator. The station's management also operates several small remote power generators including two other jet turbines identical to West Springfield 10 which are the Doreen Street unit in Pittsfield, Massachusetts, and Woodland Road unit in Lee, Massachusetts as well as five run-of-river hydroelectric power stations located on the Chicopee and Deerfield Rivers.

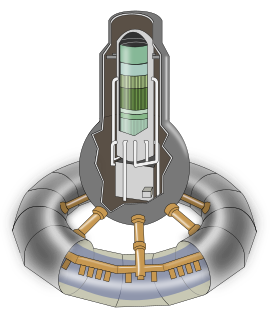

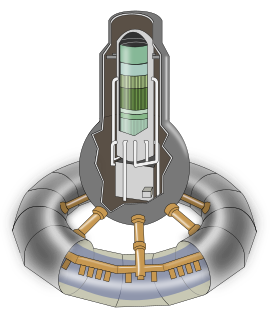

General Electric's BWR product line of boiling water reactors represents the designs of a relatively large (~18%) percentage of the commercial fission reactors around the world.

Butibori Power Project is a coal-based thermal power plant located at Butibori near Nagpur in the Indian state of Maharashtra. The power plant is operated by the Reliance Power.

Reftinskaya GRES is the largest solid fuel thermal power plant in Russia. It is situated in Sverdlovsk Oblast, 100 km north-east of Yekaterinburg and 18 km from Asbest. Reftinskiy town, which is home to 18,000 people, is situated 2.5 km from the GRES, which produces 20,000 million KWh annually. It has a total installed capacity of 3,800 and heat power— 350 GKh. Coal from Ekibastuz's coal field is used as the main fuel and the black oil is used as the starting fuel. GRES produces power with the bar «Outdoor switchgear -500 kV» on five power lines -500 kV and with the bar «Outdoor switchgear -220 kV» on five power lines -220 kV. The station supplies power to the industrial areas in Sverdlovsk, Tyumen, Perm and Chelyabinsk regions. The construction of the electric power station was started in 1963, the launching of the first power unit took place in 1970 and in 1980 – of the last one.

Yerevan Thermal Power Plant, is a thermal power plant located about 10 kilometres (6.2 mi) from Yerevan, Armenia. An older, obsolete plant was fueled by natural gas and fuel oil, while the new combined-cycle plant is powered by natural gas and has a capacity of 242 megawatts. It produces a quarter of the country's electricity and is responsible for seasonal electricity swaps with Iran. The director general of the power plant is Hovakim Hovhannisyan.

Sredneuralskaya GRES is a power plant in Sredneuralsk, Sverdlovsk Oblast, Russia. It is a subsidiary of Enel Russia.

Nevinnomysskaya GRES is a power plant of federal importance located in Nevinnomyssk, Stavropol krai, Northern Caucasus federal area. It is a subsidiary of Enel Russia.