Coal tar is a thick dark liquid which is a by-product of the production of coke and coal gas from coal. It is a type of creosote. It has both medical and industrial uses. Medicinally it is a topical medication applied to skin to treat psoriasis and seborrheic dermatitis (dandruff). It may be used in combination with ultraviolet light therapy. Industrially it is a railroad tie preservative and used in the surfacing of roads. Coal tar was listed as a known human carcinogen in the first Report on Carcinogens from the U.S. Federal Government.

Spinning is a twisting technique to form yarn from fibers. The fiber intended is drawn out, twisted, and wound onto a bobbin. A few popular fibers that are spun into yarn other than cotton, which is the most popular, are viscose, and synthetic polyester. Originally done by hand using a spindle whorl, starting in the 500s AD the spinning wheel became the predominant spinning tool across Asia and Europe. The spinning jenny and spinning mule, invented in the late 1700s, made mechanical spinning far more efficient than spinning by hand, and especially made cotton manufacturing one of the most important industries of the Industrial Revolution.

Mineral wool is any fibrous material formed by spinning or drawing molten mineral or rock materials such as slag and ceramics.

Percivall Pott was an English surgeon, one of the founders of orthopaedics, and the first scientist to demonstrate that a cancer may be caused by an environmental carcinogen.

Mineral oil is any of various colorless, odorless, light mixtures of higher alkanes from a mineral source, particularly a distillate of petroleum, as distinct from usually edible vegetable oils.

A chimney sweep is a person who clears ash and soot from chimneys. The chimney uses the pressure difference caused by a hot column of gas to create a draught and draw air over the hot coals or wood enabling continued combustion. Chimneys may be straight or contain many changes of direction. During normal operation, a layer of creosote builds up on the inside of the chimney, restricting the flow. The creosote can also catch fire, setting the chimney and the building alight. The chimney must be swept to remove the soot. This was done by the master sweep.

The spinning jenny is a multi-spindle spinning frame, and was one of the key developments in the industrialization of textile manufacturing during the early Industrial Revolution. It was invented in 1764 or 1765 by James Hargreaves in Stanhill, Oswaldtwistle, Lancashire in England.

Squamous-cell skin cancer, also known as cutaneous squamous-cell carcinoma (cSCC), is one of the main types of skin cancer along with basal cell cancer and melanoma. It usually presents as a hard lump with a scaly top but can also form an ulcer. Onset is often over months. Squamous-cell skin cancer is more likely to spread to distant areas than basal cell cancer. When confined to the outermost layer of the skin, a precancerous or in situ form of cSCC is known as Bowen's disease.

A cotton mill is a building that houses spinning or weaving machinery for the production of yarn or cloth from cotton, an important product during the Industrial Revolution in the development of the factory system.

Benzo[a]pyrene is a polycyclic aromatic hydrocarbon and the result of incomplete combustion of organic matter at temperatures between 300 °C (572 °F) and 600 °C (1,112 °F). The ubiquitous compound can be found in coal tar, tobacco smoke and many foods, especially grilled meats. The substance with the formula C20H12 is one of the benzopyrenes, formed by a benzene ring fused to pyrene. Its diol epoxide metabolites (more commonly known as BPDE) react with and bind to DNA, resulting in mutations and eventually cancer. It is listed as a Group 1 carcinogen by the IARC. In the 18th century a scrotal cancer of chimney sweepers, the chimney sweeps' carcinoma, was already known to be connected to soot.

An occupational disease is any chronic ailment that occurs as a result of work or occupational activity. It is an aspect of occupational safety and health. An occupational disease is typically identified when it is shown that it is more prevalent in a given body of workers than in the general population, or in other worker populations. The first such disease to be recognised, squamous-cell carcinoma of the scrotum, was identified in chimney sweep boys by Sir Percival Pott in 1775. Occupational hazards that are of a traumatic nature are not considered to be occupational diseases.

Substances, mixtures, and exposure circumstances in this list have been classified as group 1 by the International Agency for Research on Cancer (IARC): The agent (mixture) is carcinogenic to humans. The exposure circumstance entails exposures that are carcinogenic to humans. This category is used when there is sufficient evidence of carcinogenicity in humans. Exceptionally, an agent (mixture) may be placed in this category when evidence of carcinogenicity in humans is less than sufficient but there is sufficient evidence of carcinogenicity in experimental animals and strong evidence in exposed humans that the agent (mixture) acts through a relevant mechanism of carcinogenicity.

The spinning mule is a machine used to spin cotton and other fibres. They were used extensively from the late 18th to the early 20th century in the mills of Lancashire and elsewhere. Mules were worked in pairs by a minder, with the help of two boys: the little piecer and the big or side piecer. The carriage carried up to 1,320 spindles and could be 150 feet (46 m) long, and would move forward and back a distance of 5 feet (1.5 m) four times a minute. It was invented between 1775 and 1779 by Samuel Crompton. The self-acting (automatic) mule was patented by Richard Roberts in 1825. At its peak there were 50,000,000 mule spindles in Lancashire alone. Modern versions are still in niche production and are used to spin woollen yarns from noble fibres such as cashmere, ultra-fine merino and alpaca for the knitware market.

Cotton-spinning machinery refers to machines which process prepared cotton roving into workable yarn or thread. Such machinery can be dated back centuries. During the 18th and 19th centuries, as part of the Industrial Revolution cotton-spinning machinery was developed to bring mass production to the cotton industry. Cotton spinning machinery was installed in large factories, commonly known as cotton mills.

Spinning is an ancient textile art in which plant, animal or synthetic fibres are drawn out and twisted together to form yarn. For thousands of years, fibre was spun by hand using simple tools, the spindle and distaff. It was only with the invention of the spinning wheel in the Islamic world circa 1030, and its subsequent introduction to China, India and Europe in the High Middle Ages, that the output of individual spinners dramatically increased. Mass production later arose in the 18th century with the beginnings of the Industrial Revolution. Hand-spinning remains a popular handicraft.

Marico Limited is an Indian multinational consumer goods company providing consumer products and services in the areas of health, beauty and wellness. With its headquarters in Mumbai, Marico is present in over 25 countries across Asia and Africa. It owns brands in categories of hair care, skin care, edible oils, health foods, male grooming, and fabric care such as Parachute, Saffola, Hair & Care, Parachute Advanced, Nihar Naturals, and Mediker.

Liquid paraffin, also known as paraffinum liquidum, paraffin oil, liquid paraffin oil or Russian mineral oil, is a very highly refined mineral oil used in cosmetics and medicine. Cosmetic or medicinal liquid paraffin should not be confused with the paraffin used as a fuel. The generic sense of paraffin meaning alkane led to regional differences for the meanings of both paraffin and paraffin oil. It is a transparent, colorless, nearly odorless, and oily liquid that is composed of saturated hydrocarbons derived from petroleum.

Helmshore Mills are two mills built on the River Ogden in Helmshore, Lancashire. Higher Mill was built in 1796 for William Turner, and Whitaker's Mill was built in the 1820s by the Turner family. In their early life they alternated between working wool and cotton. By 1920 they were working shoddy as condensor mule mills; and equipment has been preserved and is still used. The mills closed in 1967 and they were taken over by the Higher Mills Trust, whose trustees included historian and author Chris Aspin and politician Dr Rhodes Boyson, who maintained it as a museum. The mills are said to the most original and best-preserved examples of both cotton spinning and woollen fulling left in the country that are still operational.

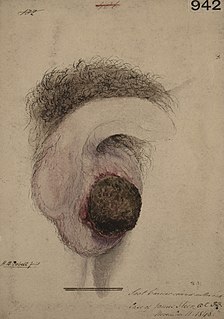

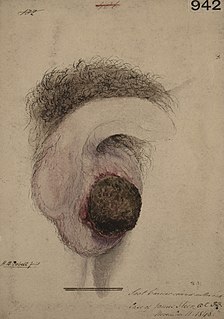

Chimney sweep's cancer, also called soot wart, is a squamous cell carcinoma of the skin of the scrotum. It has the distinction of being the first reported form of occupational cancer, and was initially identified by Percivall Pott in 1775. It was initially noticed as being prevalent amongst chimney sweeps. The disease was also seen in men exposed to mineral oil and those who worked with coal distillates.

Ring spinning is a spindle-based method of spinning fibres, such as cotton, flax or wool, to make a yarn. The ring frame developed from the throstle frame, which in its turn was a descendant of Arkwright's water frame. Ring spinning is a continuous process, unlike mule spinning which uses an intermittent action. In ring spinning, the roving is first attenuated by using drawing rollers, then spun and wound around a rotating spindle which in its turn is contained within an independently rotating ring flyer. Traditionally ring frames could only be used for the coarser counts, but they could be attended by semi-skilled labour.