A grape is a fruit, botanically a berry, of the deciduous woody vines of the flowering plant genus Vitis. Grapes are a non-climacteric type of fruit, generally occurring in clusters.

Winemaking or vinification is the production of wine, starting with the selection of the fruit, its fermentation into alcohol, and the bottling of the finished liquid. The history of wine-making stretches over millennia. There are authentic proofs that suggest that the earliest Wine production took place in Georgia and Iran around 6000 to 5000 B.C. The science of wine and winemaking is known as oenology. A winemaker may also be called a vintner. The growing of grapes is viticulture and there are many varieties of grapes.

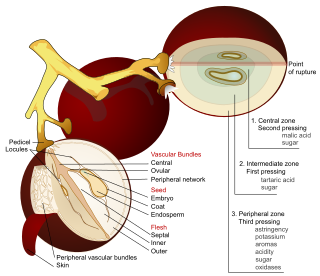

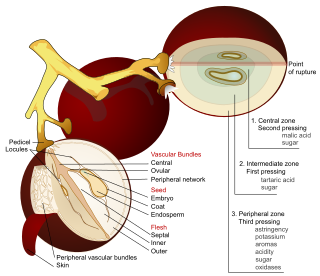

Must is freshly crushed fruit juice that contains the skins, seeds, and stems of the fruit. The solid portion of the must is called pomace and typically makes up 7–23% of the total weight of the must. Making must is the first step in winemaking. Because of its high glucose content, typically between 10 and 15%, must is also used as a sweetener in a variety of cuisines. Unlike commercially sold grape juice, which is filtered and pasteurized, must is thick with particulate matter, opaque, and comes in various shades of brown and purple.

Pomace, or marc, is the solid remains of grapes, olives, or other fruit after pressing for juice or oil. It contains the skins, pulp, seeds, and stems of the fruit.

Carbonic maceration is a winemaking technique, often associated with the French wine region of Beaujolais, in which whole grapes are fermented in a carbon dioxide rich environment before crushing. Conventional alcoholic fermentation involves crushing the grapes to free the juice and pulp from the skin with yeast serving to convert sugar into ethanol. Carbonic maceration ferments most of the juice while it is still inside the grape, although grapes at the bottom of the vessel are crushed by gravity and undergo conventional fermentation. The resulting wine is fruity with very low tannins. It is ready to drink quickly but lacks the structure for long-term aging. In extreme cases such as Beaujolais nouveau, the period between picking and bottling can be less than six weeks.

Red wine is a type of wine made from dark-colored grape varieties. The color of the wine can range from intense violet, typical of young wines, through to brick red for mature wines and brown for older red wines. The juice from most purple grapes is greenish-white, the red color coming from anthocyan pigments present in the skin of the grape. Much of the red wine production process involves extraction of color and flavor components from the grape skin.

A rosé is a type of wine that incorporates some of the color from the grape skins, but not enough to qualify it as a red wine. It may be the oldest known type of wine, as it is the most straightforward to make with the skin contact method. The pink color can range from a pale "onionskin" orange to a vivid near-purple, depending on the grape varieties used and winemaking techniques. Usually, the wine is labelled rosé in French, Portuguese, and English-speaking countries, rosado in Spanish, or rosato in Italian.

A winepress is a device used to extract juice from crushed grapes during winemaking. There are a number of different styles of presses that are used by wine makers but their overall functionality is the same. Each style of press exerts controlled pressure in order to free the juice from the fruit. The pressure must be controlled, especially with grapes, in order to avoid crushing the seeds and releasing a great deal of undesirable tannins into the wine. Wine was being made at least as long ago as 4000 BC; in 2011, a winepress was unearthed in Armenia with red wine dated 6,000 years old.

Maceration is the winemaking process where the phenolic materials of the grape—tannins, coloring agents (anthocyanins) and flavor compounds—are leached from the grape skins, seeds and stems into the must. To macerate is to soften by soaking, and maceration is the process by which the red wine receives its red color, since raw grape juice is clear-grayish in color. In the production of white wines, maceration is either avoided or allowed only in very limited manner in the form of a short amount of skin contact with the juice prior to pressing. This is more common in the production of varietals with less natural flavor and body structure like Sauvignon blanc and Sémillon. For Rosé, red wine grapes are allowed some maceration between the skins and must, but not to the extent of red wine production.

The following outline is provided as an overview of and topical guide to wine:

The harvesting of wine grapes (vintage) is one of the most crucial steps in the process of wine-making. The time of harvest is determined primarily by the ripeness of the grape as measured by sugar, acid and tannin levels with winemakers basing their decision to pick based on the style of wine they wish to produce. The weather can also shape the timetable of harvesting with the threat of heat, rain, hail, and frost which can damage the grapes and bring about various vine diseases. In addition to determining the time of the harvest, winemakers and vineyard owners must also determine whether to use hand pickers or mechanical harvesters. The harvest season typically falls between August & October in the Northern Hemisphere and February & April in the Southern Hemisphere. With various climate conditions, grape varieties, and wine styles the harvesting of grapes could happen in every month of the calendar year somewhere in the world. In the New World it is often referred to as the crush.

The acids in wine are an important component in both winemaking and the finished product of wine. They are present in both grapes and wine, having direct influences on the color, balance and taste of the wine as well as the growth and vitality of yeast during fermentation and protecting the wine from bacteria. The measure of the amount of acidity in wine is known as the “titratable acidity” or “total acidity”, which refers to the test that yields the total of all acids present, while strength of acidity is measured according to pH, with most wines having a pH between 2.9 and 3.9. Generally, the lower the pH, the higher the acidity in the wine. There is no direct connection between total acidity and pH. In wine tasting, the term “acidity” refers to the fresh, tart and sour attributes of the wine which are evaluated in relation to how well the acidity balances out the sweetness and bitter components of the wine such as tannins. Three primary acids are found in wine grapes: tartaric, malic, and citric acids. During the course of winemaking and in the finished wines, acetic, butyric, lactic, and succinic acids can play significant roles. Most of the acids involved with wine are fixed acids with the notable exception of acetic acid, mostly found in vinegar, which is volatile and can contribute to the wine fault known as volatile acidity. Sometimes, additional acids, such as ascorbic, sorbic and sulfurous acids, are used in winemaking.

The phenolic content in wine refers to the phenolic compounds—natural phenol and polyphenols—in wine, which include a large group of several hundred chemical compounds that affect the taste, color and mouthfeel of wine. These compounds include phenolic acids, stilbenoids, flavonols, dihydroflavonols, anthocyanins, flavanol monomers (catechins) and flavanol polymers (proanthocyanidins). This large group of natural phenols can be broadly separated into two categories, flavonoids and non-flavonoids. Flavonoids include the anthocyanins and tannins which contribute to the color and mouthfeel of the wine. The non-flavonoids include the stilbenoids such as resveratrol and phenolic acids such as benzoic, caffeic and cinnamic acids.

This glossary of winemaking terms lists some of terms and definitions involved in making wine, fruit wine, and mead.

In winemaking, clarification and stabilization are the processes by which insoluble matter suspended in the wine is removed before bottling. This matter may include dead yeast cells (lees), bacteria, tartrates, proteins, pectins, various tannins and other phenolic compounds, as well as pieces of grape skin, pulp, stems and gums. Clarification and stabilization may involve fining, filtration, centrifugation, flotation, refrigeration, pasteurization, and/or barrel maturation and racking.

In viticulture, ripeness is the completion of the ripening process of wine grapes on the vine which signals the beginning of harvest. What exactly constitutes ripeness will vary depending on what style of wine is being produced and what the winemaker and viticulturist personally believe constitutes ripeness. Once the grapes are harvested, the physical and chemical components of the grape which will influence a wine's quality are essentially set so determining the optimal moment of ripeness for harvest may be considered the most crucial decision in winemaking.

Léon Millot is a red variety of hybrid grape used for wine. It was created in 1911 in the Oberlin Institute in Colmar, Alsace, by the French viticulturist Eugène Kuhlmann (1858–1932) by crossing the hybrid grape Millardet et de Grasset 101-14 O.P. with Goldriesling, which is Vitis vinifera. The variety was named after the winemaker and tree nursery owner Léon Millot.

Kvevri or Qvevri - also known as Ch'uri in Western Georgia - are large earthenware vessels used for the fermentation, storage and ageing of traditional Georgian wine. Resembling large, egg-shaped amphorae without handles, they are either buried below ground or set into the floors of large wine cellars. Kvevris vary in size: volumes range from 20 litres to around 10,000; 800 is typical.

The history of the wine press and of pressing is nearly as old as the history of wine itself with the remains of wine presses providing some of the longest-serving evidence of organised viticulture and winemaking in the ancient world. The earliest wine press was probably the human foot or hand, crushing and squeezing grapes into a bag or container where the contents would ferment.

The role of yeast in winemaking is the most important element that distinguishes wine from fruit juice. In the absence of oxygen, yeast converts the sugars of the fruit into alcohol and carbon dioxide through the process of fermentation. The more sugars in the grapes, the higher the potential alcohol level of the wine if the yeast are allowed to carry out fermentation to dryness. Sometimes winemakers will stop fermentation early in order to leave some residual sugars and sweetness in the wine such as with dessert wines. This can be achieved by dropping fermentation temperatures to the point where the yeast are inactive, sterile filtering the wine to remove the yeast or fortification with brandy or neutral spirits to kill off the yeast cells. If fermentation is unintentionally stopped, such as when the yeasts become exhausted of available nutrients and the wine has not yet reached dryness, this is considered a stuck fermentation.