Underground hard-rock mining refers to various underground mining techniques used to excavate "hard" minerals, usually those containing metals, such as ore containing gold, silver, iron, copper, zinc, nickel, tin, and lead. It also involves the same techniques used to excavate ores of gems, such as diamonds and rubies. Soft-rock mining refers to the excavation of softer minerals, such as salt, coal, and oil sands.

A borehole is a narrow shaft bored in the ground, either vertically or horizontally. A borehole may be constructed for many different purposes, including the extraction of water, other liquids, or gases. It may also be part of a geotechnical investigation, environmental site assessment, mineral exploration, temperature measurement, as a pilot hole for installing piers or underground utilities, for geothermal installations, or for underground storage of unwanted substances, e.g. in carbon capture and storage.

Lengede is a municipality in the district of Peine, in Lower Saxony, Germany, some 18 kilometers southwest of Braunschweig and 40 kilometers southeast of Hanover. It became known to the world in 1963 because of a mining disaster and the subsequent rescue operation of eleven surviving miners, which became known as the "Wunder von Lengede".

The Knox Mine disaster was a mining accident on January 22, 1959, at the River Slope Mine in Jenkins Township, Pennsylvania.

The Sago Mine disaster was a coal mine explosion on January 2, 2006, at the Sago Mine in Sago, West Virginia, United States, near the Upshur County seat of Buckhannon. The blast and collapse trapped 13 miners for nearly two days; only one survived. It was the worst mining disaster in the United States since the Jim Walter Resources Mine disaster in Alabama on September 23, 2001, and the worst disaster in West Virginia since the 1968 Farmington Mine disaster. It was exceeded four years later by the Upper Big Branch Mine disaster, also a coal mine explosion in West Virginia, which killed 29 miners in April 2010.

The Hartley Colliery disaster was a coal mining accident in Northumberland, England, that occurred on 16 January 1862 and resulted in the deaths of 204 men and children. The beam of the pit's pumping engine broke and fell down the shaft, trapping the men below. The disaster prompted a change in British law that required all collieries to have at least two independent means of escape.

Levant Mine and Beam Engine is a National Trust property at Trewellard, Pendeen, near St Just, Cornwall, England, UK. Its main attraction is that it has the world's only Cornish beam engine still operated by steam on its original site. There is also a visitor centre, a short underground tour, and the South West Coast Path leads to Botallack Mine, via a cliff-top footpath.

Kellingley Colliery, known affectionately as the 'Big K', was a deep coal mine in North Yorkshire, England, 3.6 miles (5.8 km) east of Ferrybridge power station. It was owned and operated by UK Coal.

The Crandall Canyon Mine, formerly Genwal Mine, was an underground bituminous coal mine in northwestern Emery County, Utah.

The Avondale Colliery was a coal mine in Plymouth Township, Luzerne County, near Plymouth, Pennsylvania in the small town of Avondale. The mine was considered to be "one of the best and worst" operating in Pennsylvania's Wyoming Valley.

The Avondale Mine disaster was a massive fire at the Avondale Colliery near Plymouth Township, Pennsylvania, on September 6, 1869. It caused the death of 110 workers. It started when the wooden lining of the mine shaft caught fire and ignited the coal breaker built directly overhead. The shaft was the only entrance and exit to the mine, and the fire trapped and suffocated 108 of the workers. It was the greatest mine disaster to that point in American history.

The 2010 Copiapó mining accident, also known then as the "Chilean mining accident", began on 5 August 2010, with a cave-in at the San José copper–gold mine, located in the Atacama Desert 45 kilometers (28 mi) north of the regional capital of Copiapó, in northern Chile. Thirty-three men were trapped 700 meters (2,300 ft) underground and 5 kilometers (3 mi) from the mine's entrance, and were rescued after 69 days.

A Dahlbusch Bomb is an emergency evacuation device for use in mining. In its original form it is a torpedo-shaped cylinder with a length of 2.5 metres, developed to transport trapped miners through boreholes after mining accidents. It does not contain explosives: it was called a "bomb" because of its shape.

Center Rock, Inc. is a manufacturer of drilling equipment headquartered in Berlin, Pennsylvania. The company was founded in 1998 by Brandon W. Fisher.

Layne Christensen Company is a U.S.-based global water management, construction and drilling company. The company has two divisions, which are Water Resources-Mineral Services and Inline.

Schramm, Inc. is a privately held manufacturer of mobile, top-head hydraulic drilling rigs and related equipment for the global mining, energy, and water well industries. In October 2019, it was acquired by GenNx360 Capital Partners. It is headquartered in West Chester, Pennsylvania in the United States. Schramm affiliated sales, parts, and service centers are located in more than 16 countries across the globe, with its primary manufacturing facilities located in Pennsylvania and Western Australia.

The Sheppton Mine disaster and rescue in Sheppton, Pennsylvania, United States, was one of the first rescues of trapped miners accomplished by raising them through holes bored through solid rock, an event that gripped the world's attention during August 1963.

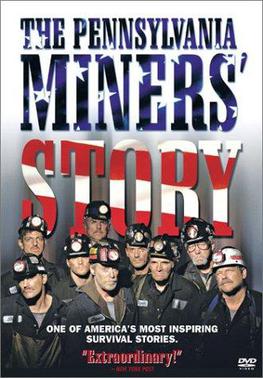

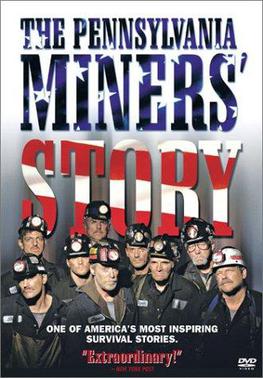

The Pennsylvania Miners' Story is a 2002 television film. It was written by Elwood Reid and directed by David Frankel. The film is based on the real events occurred at the Quecreek Mine. It was mostly filmed on location at Somerset County, Pennsylvania and some scenes were shot on the actual Quecreek Mine. "The Pennsylvania Miners' Story" was first aired at ABC on November 24, 2002.

Scientific ice drilling began in 1840, when Louis Agassiz attempted to drill through the Unteraargletscher in the Alps. Rotary drills were first used to drill in ice in the 1890s, and thermal drilling, with a heated drillhead, began to be used in the 1940s. Ice coring began in the 1950s, with the International Geophysical Year at the end of the decade bringing increased ice drilling activity. In 1966, the Greenland ice sheet was penetrated for the first time with a 1,388 m hole reaching bedrock, using a combination of thermal and electromechanical drilling. Major projects over the following decades brought cores from deep holes in the Greenland and Antarctic ice sheets.

The Meghalaya mining accident happened on 13 December 2018, when 15 miners were trapped in a mine in Ksan, in the Indian state of Meghalaya. While five miners managed to escape, rescue efforts for the remaining 10 continued till 2 March 2019. The miners were trapped inside the coal mine at a depth of around 370 feet in Jaintia Hills district after digging with the rat-hole mining technique. The tunnel the miners were in flooded with water after they cut into an adjacent mine which was full of water from the nearby Lytein river.