An oil platform is a large structure with facilities to extract and process petroleum and natural gas that lie in rock formations beneath the seabed. Many oil platforms will also have facilities to accommodate the workers, although it is also common to have a separate accommodation platform bridge linked to the production platform. Most commonly, oil platforms engage in activities on the continental shelf, though they can also be used in lakes, inshore waters, and inland seas. Depending on the circumstances, the platform may be fixed to the ocean floor, consist of an artificial island, or float. In some arrangements the main facility may have storage facilities for the processed oil. Remote subsea wells may also be connected to a platform by flow lines and by umbilical connections. These sub-sea facilities may include of one or more subsea wells or manifold centres for multiple wells.

Iolair is a specialised semi-submersible offshore platform designed for BP to support and service oil platforms in the North Sea and served as an emergency support vessel (ESV) in the Forties Oil Field. Since 2000 it has been working in the Cantarell Field, Mexico as an offshore construction and maintenance service vessel operated by Cotemar S.A de C.V.

In the oil and gas industry, the term wireline usually refers to the use of multi-conductor, single conductor or slickline cable, or "wireline", as a conveyance for the acquisition of subsurface petrophysical and geophysical data and the delivery of well construction services such as pipe recovery, perforating, plug setting and well cleaning and fishing. The subsurface geophysical and petrophysical information results in the description and analysis of subsurface geology, reservoir properties and production characteristics.

In petroleum and natural gas extraction, a Christmas tree, or "tree", is an assembly of valves, casing spools, and fittings used to regulate the flow of pipes in an oil well, gas well, water injection well, water disposal well, gas injection well, condensate well, and other types of well.

A drillship is a merchant vessel designed for use in exploratory offshore drilling of new oil and gas wells or for scientific drilling purposes. In recent years the vessels have been used in deepwater and ultra-deepwater applications, equipped with the latest and most advanced dynamic positioning systems.

NOV Inc., formerly National Oilwell Varco, is an American multinational corporation based in Houston, Texas. It is a worldwide provider of equipment and components used in oil and gas drilling and production operations, oilfield services, and supply chain integration services to the upstream oil and gas industry. The company conducts operations in more than 500 locations across six continents, operating through three reporting segments: Rig Technologies, Wellbore Technologies, and Completion & Production Solutions.

A drilling rig is used to create a borehole or well in the earth's sub-surface, for example in order to extract natural resources such as gas or oil. During such drilling, data is acquired from the drilling rig sensors for a range of purposes such as: decision-support to monitor and manage the smooth operation of drilling; to make detailed records of the geologic formations penetrated by a borehole; to generate operations statistics and performance benchmarks such that improvements can be identified, and to provide well planners with accurate historical operations-performance data with which to perform statistical risk analysis for future well operations. The terms measurement while drilling (MWD), and logging while drilling (LWD) are not used consistently throughout the industry. Although these terms are related, within the context of this section, the term MWD refers to directional-drilling measurements, e.g., for decision support for the wellbore path, while LWD refers to measurements concerning the geological formations penetrated while drilling.

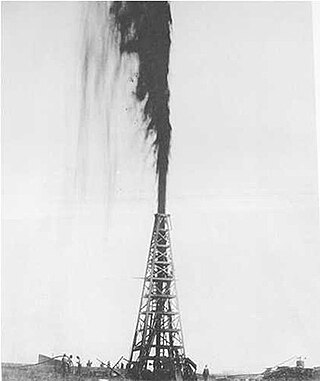

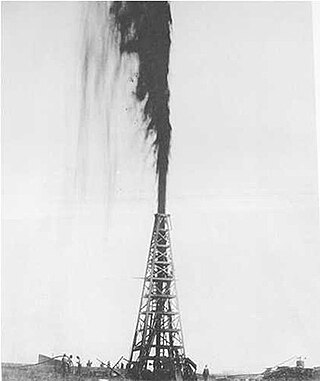

A blowout is the uncontrolled release of crude oil and/or natural gas from an oil well or gas well after pressure control systems have failed. Modern wells have blowout preventers intended to prevent such an occurrence. An accidental spark during a blowout can lead to a catastrophic oil or gas fire.

Petroleum is a fossil fuel that can be drawn from beneath the earth's surface. Reservoirs of petroleum was formed through the mixture of plants, algae, and sediments in shallow seas under high pressure. Petroleum is mostly recovered from oil drilling. Seismic surveys and other methods are used to locate oil reservoirs. Oil rigs and oil platforms are used to drill long holes into the earth to create an oil well and extract petroleum. After extraction, oil is refined to make gasoline and other products such as tires and refrigerators. Extraction of petroleum can be dangerous and have led to oil spills.

In the oil and gas industries, coiled tubing refers to a very long metal pipe, normally 1 to 3.25 in in diameter which is supplied spooled on a large reel. It is used for interventions in oil and gas wells and sometimes as production tubing in depleted gas wells. Coiled tubing is often used to carry out operations similar to wirelining. The main benefits over wireline are the ability to pump chemicals through the coil and the ability to push it into the hole rather than relying on gravity. Pumping can be fairly self-contained, almost a closed system, since the tube is continuous instead of jointed pipe. For offshore operations, the 'footprint' for a coiled tubing operation is generally larger than a wireline spread, which can limit the number of installations where coiled tubing can be performed and make the operation more costly. A coiled tubing operation is normally performed through the drilling derrick on the oil platform, which is used to support the surface equipment, although on platforms with no drilling facilities a self-supporting tower can be used instead. For coiled tubing operations on sub-sea wells a mobile offshore drilling unit (MODU) e.g. semi-submersible, drillship etc. has to be utilized to support all the surface equipment and personnel, whereas wireline can be carried out from a smaller and cheaper intervention vessel. Onshore, they can be run using smaller service rigs, and for light operations a mobile self-contained coiled tubing rig can be used.

A well intervention, or well work, is any operation carried out on an oil or gas well during, or at the end of, its productive life that alters the state of the well or well geometry, provides well diagnostics, or manages the production of the well.

Subsea technology involves fully submerged ocean equipment, operations, or applications, especially when some distance offshore, in deep ocean waters, or on the seabed. The term subsea is frequently used in connection with oceanography, marine or ocean engineering, ocean exploration, remotely operated vehicle (ROVs) autonomous underwater vehicles (AUVs), submarine communications or power cables, seafloor mineral mining, oil and gas, and offshore wind power.

The Schiehallion oilfield is a deepwater offshore oilfield approximately 175 kilometres (110 mi) west of the Shetland Islands in the North Atlantic Ocean. The Schiehallion and adjacent Loyal field were jointly developed by BP on behalf of the Schiehallion field partners; BP, Shell, Amerada Hess, Murphy Oil, Statoil and OMV, and the Loyal field partners; BP and Shell.

A Normally Unmanned Installation (NUI) is a type of automated offshore Oil/Gas platform designed to be primarily operated remotely, without the constant presence of personnel.

In 2017 the department was merged with the Department of Geology and Mineral Resources Engineering, forming the new Department of Geoscience and Petroleum.

Well stimulation is a well intervention performed on an oil or gas well to increase production by improving the flow of hydrocarbons from the reservoir into the well bore. It may be done using a well stimulator structure or using off shore ships / drilling vessels, also known as "Well stimulation vessels".

Helix Energy Solutions Inc., known as Cal Dive International prior to 2006, is an American oil and gas services company headquartered in Houston, Texas. The company is a global provider of offshore services in well intervention and ROV operations of new and existing oil and gas fields.

Well Enhancer is a purpose-built well intervention vessel, launched at the IHC Krimpen Shipyard on May 31, 2008, in Krimpen aan den IJssel, the Netherlands.

GE Oil & Gas was the division of General Electric that owned its investments in the petroleum industry. In July 2017, this division was merged with Baker Hughes.