Friction is the force resisting the relative motion of solid surfaces, fluid layers, and material elements sliding against each other. Types of friction include dry, fluid, lubricated, skin, and internal -- an incomplete list. The study of the processes involved is called tribology, and has a history of more than 2000 years.

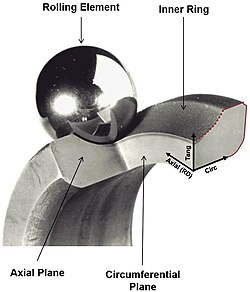

A ball bearing is a type of rolling-element bearing that uses balls to maintain the separation between the bearing races.

Fluid bearings are bearings in which the load is supported by a thin layer of rapidly moving pressurized liquid or gas between the bearing surfaces. Since there is no contact between the moving parts, there is no sliding friction, allowing fluid bearings to have lower friction, wear and vibration than many other types of bearings. Thus, it is possible for some fluid bearings to have near-zero wear if operated correctly.

A bearing is a machine element that constrains relative motion to only the desired motion and reduces friction between moving parts. The design of the bearing may, for example, provide for free linear movement of the moving part or for free rotation around a fixed axis; or, it may prevent a motion by controlling the vectors of normal forces that bear on the moving parts. Most bearings facilitate the desired motion by minimizing friction. Bearings are classified broadly according to the type of operation, the motions allowed, or the directions of the loads (forces) applied to the parts.

Lubrication is the process or technique of using a lubricant to reduce friction and wear and tear in a contact between two surfaces. The study of lubrication is a discipline in the field of tribology.

Wear is the damaging, gradual removal or deformation of material at solid surfaces. Causes of wear can be mechanical or chemical. The study of wear and related processes is referred to as tribology.

Tribology is the science and engineering of understanding friction, lubrication and wear phenomena for interacting surfaces in relative motion. It is highly interdisciplinary, drawing on many academic fields, including physics, chemistry, materials science, mathematics, biology and engineering. The fundamental objects of study in tribology are tribosystems, which are physical systems of contacting surfaces. Subfields of tribology include biotribology, nanotribology and space tribology. It is also related to other areas such as the coupling of corrosion and tribology in tribocorrosion and the contact mechanics of how surfaces in contact deform. Approximately 20% of the total energy expenditure of the world is due to the impact of friction and wear in the transportation, manufacturing, power generation, and residential sectors.

A plain bearing, or more commonly sliding contact bearing and slide bearing, is the simplest type of bearing, comprising just a bearing surface and no rolling elements. Therefore, the part of the shaft in contact with the bearing slides over the bearing surface. The simplest example of a plain bearing is a shaft rotating in a hole. A simple linear bearing can be a pair of flat surfaces designed to allow motion; e.g., a drawer and the slides it rests on or the ways on the bed of a lathe.

In mechanical engineering, a rolling-element bearing, also known as a rolling bearing, is a bearing which carries a load by placing rolling elements between two concentric, grooved rings called races. The relative motion of the races causes the rolling elements to roll with very little rolling resistance and with little sliding.

Rolling is a type of motion that combines rotation and translation of that object with respect to a surface, such that, if ideal conditions exist, the two are in contact with each other without sliding.

False brinelling is a bearing damage caused by fretting, with or without corrosion, that causes imprints that look similar to brinelling, but are caused by a different mechanism. False brinelling may occur in bearings which act under small oscillations or vibrations.

Rolling resistance, sometimes called rolling friction or rolling drag, is the force resisting the motion when a body rolls on a surface. It is mainly caused by non-elastic effects; that is, not all the energy needed for deformation of the wheel, roadbed, etc., is recovered when the pressure is removed. Two forms of this are hysteresis losses, and permanent (plastic) deformation of the object or the surface. Note that the slippage between the wheel and the surface also results in energy dissipation. Although some researchers have included this term in rolling resistance, some suggest that this dissipation term should be treated separately from rolling resistance because it is due to the applied torque to the wheel and the resultant slip between the wheel and ground, which is called slip loss or slip resistance. In addition, only the so-called slip resistance involves friction, therefore the name "rolling friction" is to an extent a misnomer.

Fretting refers to wear and sometimes corrosion damage of loaded surfaces in contact while they encounter small oscillatory movements tangential to the surface. Fretting is caused by adhesion of contact surface asperities, which are subsequently broken again by the small movement. This breaking causes wear debris to be formed.

A tribometer is an instrument that measures tribological quantities, such as coefficient of friction, friction force, and wear volume, between two surfaces in contact. It was invented by the 18th century Dutch scientist Musschenbroek

The stick–slip phenomenon, also known as the slip–stick phenomenon or simply stick–slip, is a type of motion exhibited by objects in contact sliding over one another. The motion of these objects is usually not perfectly smooth, but rather irregular, with brief accelerations (slips) interrupted by stops (sticks). Stick–slip motion is normally connected to friction, and may generate vibration (noise) or be associated with mechanical wear of the moving objects, and is thus often undesirable in mechanical devices. On the other hand, stick–slip motion can be useful in some situations, such as the movement of a bow across a string to create musical tones in a bowed string instrument.

Sliding is a type of motion between two surfaces in contact. This can be contrasted to rolling motion. Both types of motion may occur in bearings.

Dry lubricants or solid lubricants are materials that, despite being in the solid phase, are able to reduce friction between two surfaces sliding against each other without the need for a liquid oil medium.

Contact mechanics is the study of the deformation of solids that touch each other at one or more points. This can be divided into compressive and adhesive forces in the direction perpendicular to the interface, and frictional forces in the tangential direction. Frictional contact mechanics is the study of the deformation of bodies in the presence of frictional effects, whereas frictionless contact mechanics assumes the absence of such effects.

In fluid mechanics, the Reynolds equation is a partial differential equation governing the pressure distribution of thin viscous fluid films. It was first derived by Osborne Reynolds in 1886. The classical Reynolds Equation can be used to describe the pressure distribution in nearly any type of fluid film bearing; a bearing type in which the bounding bodies are fully separated by a thin layer of liquid or gas.

White etching cracks (WEC), or white structure flaking or brittle flaking, is a type of rolling contact fatigue (RCF) damage that can occur in bearing steels under certain conditions, such as hydrogen embrittlement, high stress, inadequate lubrication, and high temperature. WEC is characterised by the presence of white areas of microstructural alteration in the material, which can lead to the formation of small cracks that can grow and propagate over time, eventually leading to premature failure of the bearing. WEC has been observed in a variety of applications, including wind turbine gearboxes, automotive engines, and other heavy machinery. The exact mechanism of WEC formation is still a subject of research, but it is believed to be related to a combination of microstructural changes, such as phase transformations and grain boundary degradation, and cyclic loading.