Stainless steel, also known as inox, corrosion-resistant steel (CRES) and rustless steel, is an alloy of iron that is resistant to rusting and corrosion. It contains at least 10.5% chromium and usually nickel, as well as 0.2 to 2.11% carbon. Stainless steel's resistance to corrosion results from the chromium, which forms a passive film that can protect the material and self-heal in the presence of oxygen.

Surgical stainless steel is a grade of stainless steel used in biomedical applications. The most common "surgical steels" are austenitic SAE 316 stainless and martensitic SAE 440, SAE 420, and 17-4 stainless steels. There is no formal definition on what constitutes a "surgical stainless steel", so product manufacturers and distributors often apply the term to refer to any grade of corrosion resistant steel.

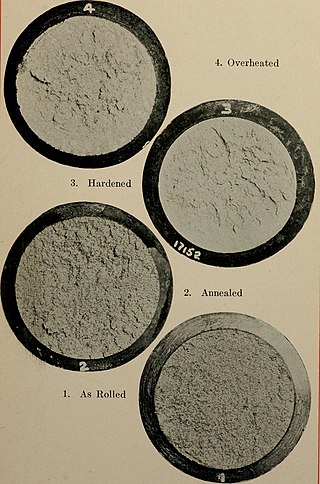

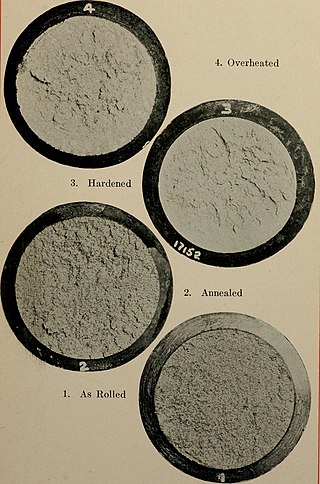

Martensitic stainless steel is a type of stainless steel alloy that has a martensite crystal structure. It can be hardened and tempered through aging and heat treatment. The other main types of stainless steel are austenitic, ferritic, duplex, and precipitation hardened.

Carbon steel is a steel with carbon content from about 0.05 up to 2.1 percent by weight. The definition of carbon steel from the American Iron and Steel Institute (AISI) states:

Tool steel is any of various carbon steels and alloy steels that are particularly well-suited to be made into tools and tooling, including cutting tools, dies, hand tools, knives, and others. Their suitability comes from their distinctive hardness, resistance to abrasion and deformation, and their ability to hold a cutting edge at elevated temperatures. As a result, tool steels are suited for use in the shaping of other materials, as for example in cutting, machining, stamping, or forging.

AL-6XN is a type of weldable stainless steel that consist of an alloy of nickel (24%), chromium (22%) and molybdenum (6.3%) with other trace elements such as nitrogen.

The weldability, also known as joinability, of a material refers to its ability to be welded. Many metals and thermoplastics can be welded, but some are easier to weld than others. A material's weldability is used to determine the welding process and to compare the final weld quality to other materials.

Alloy 20 is an austenitic stainless steel containing less than 50% iron developed for applications involving sulfuric acid. Its corrosion resistance also finds other uses in the chemical, petrochemical, power generation, and plastics industries. Alloy 20 resists pitting and chloride ion corrosion, better than 304 stainless steel and on par with 316L stainless steel. Its copper content protects it from sulfuric acid. Alloy 20 is often chosen to solve stress corrosion cracking problems, which may occur with 316L stainless. Alloy of the same name with the designation "Cb-3" indicates niobium stabilized.

In materials science, intergranular corrosion (IGC), also known as intergranular attack (IGA), is a form of corrosion where the boundaries of crystallites of the material are more susceptible to corrosion than their insides.

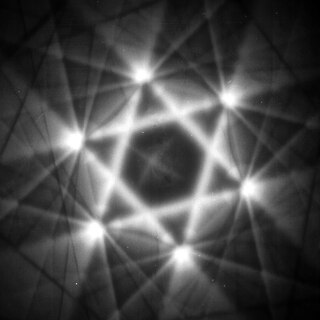

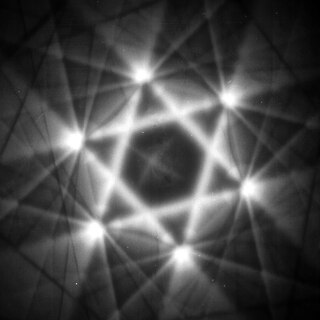

Austenitic stainless steel is one of the five classes of stainless steel by crystalline structure. Its primary crystalline structure is austenite and it prevents steels from being hardenable by heat treatment and makes them essentially non-magnetic. This structure is achieved by adding enough austenite-stabilizing elements such as nickel, manganese and nitrogen. The Incoloy family of alloys belong to the category of super austenitic stainless steels.

Alloy steel is steel that is alloyed with a variety of elements in total amounts between 1.0% and 50% by weight to improve its mechanical properties.

Zeron 100 is a super duplex stainless steel developed by Rolled Alloys. The alloy has excellent corrosion resistance combined with high strength. It typically contains 25% chromium and 7% nickel and 3.6% molybdenum along with copper and tungsten additions. Zeron 100 has a 50–50 austenitic–ferritic structure. It also has greater resistance to chloride pitting, crevice corrosion and stress corrosion cracking than exhibited by the standard 300 series stainless steels.

SAF 2205, is a Alleima-owned trademark for a 22Cr duplex (ferritic-austenitic) stainless steel. SAF derives from Sandvik Austenite Ferrite. The nominal chemical composition of SAF 2205 is 22% chromium, 5% nickel, 3.2% molybdenum and other alloying elements such as nitrogen and manganese. The UNS designation for SAF 2205 is S31803/S32205 and the EN steel no. is 1.4462. SAF 2205 or Duplex 2205 is often used as an alternative to expensive 904L stainless steel owing to similar properties but cheaper ingredients. Duplex stainless steel is available in multiple forms like bars, billets, pipes, tubes, sheets, plates and even processed to fittings and flanges.

SAE 304 stainless steel is the most common stainless steel. The steel contains both chromium and nickel metals as the main non-iron constituents. It is an austenitic stainless steel, and is therefore not magnetic. It is less electrically and thermally conductive than carbon steel. It has a higher corrosion resistance than regular steel and is widely used because of the ease in which it is formed into various shapes.

SAE 310S stainless steel is the low carbon version of 310 and is suggested for applications where sensitisation, and subsequent corrosion by high temperature gases or condensates during shutdown may pose a problem.

SAE Type 630 stainless steel is a grade of martensitic precipitation hardened stainless steel. It contains approximately 15–17.5% chromium and 3–5% nickel, as well as 3–5% copper. The name comes from the chemical makeup which is approximately 17% chromium and 4% nickel. SUS630 is the same as 17-4PH, and they both refer to the same grade.

SAE 316L grade stainless steel, sometimes referred to as A4 stainless steel or marine grade stainless steel, is the second most common austenitic stainless steel after 304/A2 stainless steel. Its primary alloying constituents after iron, are chromium, nickel (10–12%) and molybdenum (2–3%), with small (<1%) quantities of silicon, phosphorus & sulfur also present. The addition of molybdenum provides greater corrosion resistance than 304, with respect to localized corrosive attack by chlorides and to general corrosion by reducing acids, such as sulfuric acid. 316L grade is the low carbon version of 316 stainless steel. When cold worked, 316 can produce high yield and tensile strengths similar to Duplex stainless grades.

904L is an austenitic stainless steel. It is softer than 316L, but its molybdenum addition gives it superior resistance to localized attack by chlorides and greater resistance reducing acids; in particular, its copper addition gives it useful corrosion resistance to all concentrations of sulphuric acid. Its high alloying content also gives it greater resistance to chloride stress corrosion cracking, but it is still susceptible. Its low carbon content makes it resistant to sensitization by welding and which prevents intergranular corrosion.

Ferritic stainless steel forms one of the five stainless steel families, the other four being austenitic, martensitic, duplex stainless steels, and precipitation hardened. For example, many of AISI 400-series of stainless steels are ferritic steels. By comparison with austenitic types, these are less hardenable by cold working, less weldable, and should not be used at cryogenic temperatures. Some types, like the 430, have excellent corrosion resistance and are very heat tolerant.