A speed nut, aka sheet metal nut or Tinnerman nut, is a type of locknut with two sheet metal prongs that act as one thread. They are made from spring steel.

A speed nut, aka sheet metal nut or Tinnerman nut, is a type of locknut with two sheet metal prongs that act as one thread. They are made from spring steel.

The fastener serves the functions of both a lock washer and a nut. As the fastener is tightened in the nut the prongs are drawn inward until they exert pressure on the root of the thread on the fastener. When the fastener is tightened, the base of the nut, which is arched, elastically deforms and applies a force to the fastener, which locks it from loosening under vibrations. [1]

There are many different types of speed nuts, mostly dependent on the shape of the nut, how it attaches to the workpiece, and what type of screw can be used. Most types are designed for either machine screws or sheet metal screws. Some nuts do not attach to the workpiece. These are usually shaped as either a rectangle, a flange nut, or a hex nut; the rectangular speed nut is also known as a flat-style speed nut. Speed nuts that attach to the workpiece usually are some form of a J-nut or U-nut. [2] [3]

The speed nut was invented in 1923 and patented in 1924 by Albert H. Tinnerman, son of George Tinnerman, who founded Tinnerman Steel Range Company. [4] The company, established in 1870, originally manufactured sheet metal kitchen ranges. However, after Tinnerman invented the nut to resolve issues with stove shipping, the invention became so successful it led the company away from building stoves to building fasteners. [5]

Tinnerman Products was formed in 1939, and evolved from the Speed Nut development with manufacturing plants in Cleveland, Ohio. A manufacturing plant was constructed on Brookpark Road in the early 1950s. Tinnerman Products later merged with Eaton Yale & Towne in 1969. [6] In 1999, Eaton sold Tinnerman to TransTechnology for $173 million. [7] In 2009, ARaymond purchased Tinnerman for an undisclosed sum. [8]

A fastener or fastening is a hardware device that mechanically joins or affixes two or more objects together. In general, fasteners are used to create non-permanent joints; that is, joints that can be removed or dismantled without damaging the joining components. Steel fasteners are usually made of stainless steel, carbon steel, or alloy steel.

A bolted joint is one of the most common elements in construction and machine design. It consists of a male threaded fastener that captures and joins other parts, secured with a matching female screw thread. There are two main types of bolted joint designs: tension joints and shear joints.

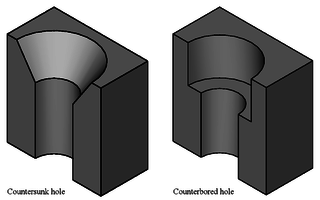

In manufacturing, a countersink is a conical hole cut into a manufactured object, or the cutter used to cut such a hole. A common use is to allow the head of a countersunk bolt, screw or rivet, when placed in the hole, to sit flush with or below the surface of the surrounding material. A countersink may also be used to remove the burr left from a drilling or tapping operation, thereby improving the finish of the product and removing any hazardous sharp edges.

A sex bolt is a type of fastener comprising a mated pair of screw and post, which are a machine screw and a nut that is barrel-shaped. The nut has a flange and a protruding boss that is internally threaded. The bolt sits within the components being fastened, and the flange provides the bearing surface.

A nyloc nut, also referred to as a nylon-insert lock nut, polymer-insert lock nut, or elastic stop nut, is a kind of locknut with a nylon collar that increases friction on the screw thread.

A cleco, also spelled generically cleko, is a temporary fastener developed by the Cleveland Pneumatic Tool Company. Widely used in the manufacture and repair of aluminum-skinned aircraft, it is used to temporarily fasten sheets of material together, or to hold parts such as stiffeners, frames etc together, before they are permanently joined.

A threaded insert, also known as a threaded bushing, is a fastener element that is inserted into an object to add a threaded hole. They may be used to repair a stripped threaded hole, provide a durable threaded hole in a soft material, place a thread on a material too thin to accept it, mold or cast threads into a work piece thereby eliminating a machining operation, or simplify changeover from unified to metric threads or vice versa.

A T-nut, T nut, or tee nut is a type of nut used to fasten a wood, particle or composite materials workpiece, leaving a flush surface.

A well nut is a blind rivet-like type of fastener used to blindly fasten a piece and to seal the bolt hole.

A distorted thread locknut, is a type of locknut that uses a deformed section of thread to keep the nut from loosening due to vibrations, or rotation of the clamped item. There are four types: elliptical offset nuts, centerlock nuts, toplock nuts and partially depitched (Philidas) nuts.

A rivet nut, also known as a blind rivet nut, or rivnut, is a one-piece internally threaded and counterbored tubular rivet that can be anchored entirely from one side. It is a kind of threaded insert. There are two types: one is designed to form a bulge on the back side of the panel as a screw is tightened in its threads. The other is similarly drawn in using a screw, but is drawn into the sleeve instead of creating a bulge.

A wingnut, wing nut or butterfly nut is a type of nut with two large metal "wings", one on each side, so it can be easily tightened and loosened by hand without tools.

A weld nut is a special type of nut specifically designed to be welded to another object. There are various types for different applications.

A barrel nut is a specialized forged nut, and is commonly used in aerospace and ready-to-assemble furniture applications.

A plate nut, also known as a nut plate, anchor nut or anchor plate, is a stamped sheet metal nut that is usually riveted to a workpiece. They have a long tube that is internally threaded and a plate with two clearance holes for rivets. The most popular versions have two lugs and they exist as fixed anchor nuts and as floating anchor nuts. The latter allows the nut to move slightly and so enlarges the positioning tolerances of the mounted parts. They were originally developed for the aerospace industry but are now also common in automotive racing.

A swage nut or self-clinching nut is a type of nut or threaded insert that is used on sheet metal.

A clip-on nut, also known as a sheet metal nut or a speed nut, is a type of nut designed to be clipped to sheet metal. It is a type of captive nut commonly made as a cage nut.

A screw is an externally helical threaded fastener capable of being tightened or released by a twisting force (torque) to the head. The most common uses of screws are to hold objects together and there are many forms for a variety of materials. Screws might be inserted into holes in assembled parts or a screw may form its own thread. The difference between a screw and a bolt is that the latter is designed to be tightened or released by torquing a nut.

A nut is a type of fastener with a threaded hole. Nuts are almost always used in conjunction with a mating bolt to fasten multiple parts together. The two partners are kept together by a combination of their threads' friction, a slight stretching of the bolt, and compression of the parts to be held together.

A bolt is an externally helical threaded fastener that fastens objects with unthreaded holes together. This is done by applying a twisting force (torque) to a matching nut. The bolt has an external male thread requiring a matching nut with a pre-formed female thread. Unlike a screw, which holds objects together by the restricting motion parallel to the axis of the screw via the normal and frictional forces between the screw's external threads and the internal threads in the objects to be fastened, a bolt prevents that linear motion via the frictional and normal forces between the bolt's external threads and the internal threads of the matching nut, which can be tightened by applying a torque which moves the nut linearly along the axis of the bolt and compresses the objects to be fastened.