Related Research Articles

Pyrotechnics is the science and craft of creating such things as fireworks, safety matches, oxygen candles, explosive bolts and other fasteners, parts of automotive airbags, as well as gas-pressure blasting in mining, quarrying, and demolition. This trade relies upon self-contained and self-sustained exothermic chemical reactions to make heat, light, gas, smoke and/or sound. The name comes from the Greek words pyr ("fire") and tekhnikos.

The flash point of a material is the "lowest liquid temperature at which, under certain standardized conditions, a liquid gives off vapours in a quantity such as to be capable of forming an ignitable vapour/air mixture".

A self-contained breathing apparatus (SCBA) is a device worn to provide an autonomous supply of breathable gas in an atmosphere that is immediately dangerous to life or health. They are typically used in firefighting and industry. The term self-contained means that the SCBA is not dependent on a remote supply of breathing gas. If designed for use under water, it is also known as a scuba set. When not used underwater, they are sometimes called industrial breathing sets. Some types are also referred to as a compressed air breathing apparatus (CABA) or simply breathing apparatus (BA). Unofficial names include air pack, air tank, oxygen cylinder or simply pack, which are mostly used in firefighting.

The autoignition temperature or self-ignition temperature, often called spontaneous ignition temperature or minimum ignition temperature and formerly also known as kindling point, of a substance is the lowest temperature in which it spontaneously ignites in a normal atmosphere without an external source of ignition, such as a flame or spark. This temperature is required to supply the activation energy needed for combustion. The temperature at which a chemical ignites decreases as the pressure is increased.

A fire door is a door with a fire-resistance rating used as part of a passive fire protection system to reduce the spread of fire and smoke between separate compartments of a structure and to enable safe egress from a building or structure or ship. In North American building codes, it, along with fire dampers, is often referred to as a closure, which can be derated compared against the fire separation that contains it, provided that this barrier is not a firewall or an occupancy separation. In Europe national standards for fire doors have been harmonised with the introduction of the new standard EN 16034, which refers to fire doors as fire-resisting door sets. Starting September 2016, a common CE marking procedure was available abolishing trade barriers within the European Union for these types of products. In the UK, it is Part B of the Building Regulations that sets out the minimum requirements for the fire protection that must be implemented in all dwellings this includes the use of fire doors. All fire doors must be installed with the appropriate fire resistant fittings, such as the frame and door hardware, for it to fully comply with any fire regulations.

A flash fire is a sudden, intense fire caused by ignition of a mixture of air and a dispersed flammable substance such as a solid, flammable or combustible liquid, or a flammable gas. It is characterized by high temperature, short duration, and a rapidly moving flame front.

In electrical and safety engineering, hazardous locations are places where fire or explosion hazards may exist. Sources of such hazards include gases, vapors, dust, fibers, and flyings, which are combustible or flammable. Electrical equipment installed in such locations can provide an ignition source, due to electrical arcing, or high temperatures. Standards and regulations exist to identify such locations, classify the hazards, and design equipment for safe use in such locations.

Fireproofing is rendering something resistant to fire, or incombustible; or material for use in making anything fire-proof. It is a passive fire protection measure. "Fireproof" or "fireproofing" can be used as a noun, verb or adjective; it may be hyphenated ("fire-proof").

Low smoke zero halogen or low smoke free of halogen is a material classification typically used for cable jacketing in the wire and cable industry. LSZH cable jacketing is composed of thermoplastic or thermoset compounds that emit limited smoke and no halogen when exposed to high sources of heat.

Passive fire protection (PFP) is components or systems of a building or structure that slows or impedes the spread of the effects of fire or smoke without system activation, and usually without movement. Examples of passive systems include floor-ceilings and roofs, fire doors, windows, and wall assemblies, fire-resistant coatings, and other fire and smoke control assemblies. Passive fire protection systems can include active components such as fire dampers.

Fire-retardant fabrics are textiles that are more resistant to fire than others through chemical treatment of flame-retardant or manufactured fireproof fibers.

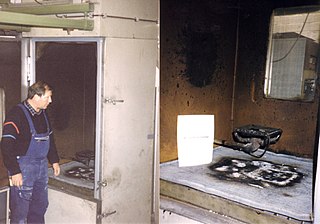

A fire test is a means of determining whether fire protection products meet minimum performance criteria as set out in a building code or other applicable legislation. Successful tests in laboratories holding national accreditation for testing and certification result in the issuance of a certification listing.

A combustible material is a material that can burn in air under certain conditions. A material is flammable if it ignites easily at ambient temperatures. In other words, a combustible material ignites with some effort and a flammable material catches fire immediately on exposure to flame.

A dust explosion is the rapid combustion of fine particles suspended in the air within an enclosed location. Dust explosions can occur where any dispersed powdered combustible material is present in high-enough concentrations in the atmosphere or other oxidizing gaseous medium, such as pure oxygen. In cases when fuel plays the role of a combustible material, the explosion is known as a fuel-air explosion.

The Comparative Tracking Index (CTI) is used to measure the electrical breakdown (tracking) properties of an insulating material. Tracking is an electrical breakdown on the surface of an insulating material wherein an initial exposure to electrical arcing heat carbonizes the material. The carbonized areas are more conductive than the pristine insulator, increasing current flow, resulting in increased heat generation, and eventually the insulation becomes completely conductive.

Flame spread, or surface burning characteristics rating, is a ranking derived by laboratory standard test methodology of a material's propensity to burn rapidly and spread flames. There are several standardized methods of determining flame spread,

Smoke-developed index is a measure of the concentration of smoke a material emits as it burns. Like the Flame Spread Index, it is based on an arbitrary scale in which asbestos-cement board has a value of 0, and red oak wood has 100. The SDI is measured using a horizontal test specimen, according to the Steiner tunnel test protocol.

Fire dampers are passive fire protection products used in heating, ventilation, and air conditioning (HVAC) ducts to prevent and isolate the spread of fire inside the ductwork through fire-resistance rated walls and floors. Fire/smoke dampers are similar to fire dampers in fire resistance rating, and also prevent the spread of smoke inside the ducts. When a rise in temperature occurs, the fire damper closes, usually activated by a thermal element which melts at temperatures higher than ambient but low enough to indicate the presence of a fire, allowing springs to close the damper blades. Fire dampers can also close following receipt of an electrical signal from a fire alarm system utilising detectors remote from the damper, indicating the sensing of heat or smoke in the building occupied spaces or in the HVAC duct system.

The Cleveland open-cup method is one of three main methods in chemistry for determining the flash point of a petroleum product using a Cleveland open-cup apparatus, also known as a Cleveland open-cup tester. First, the test cup of the apparatus is filled to a certain level with a portion of the product. Then, the temperature of this chemical is increased rapidly and then at a slow, constant rate as it approaches the theoretical flash point. The increase in temperature will cause the chemical to begin to produce flammable vapor in increasing quantities and density. The lowest temperature at which a small test flame passing over the surface of the liquid causes the vapor to ignite is considered the chemical's flash point. This apparatus may also be used to determine the chemical's fire point which is considered to have been reached when the application of the test flame produces at least five continuous seconds of ignition. Temperature range of this apparatus is 120 to 250 degree c

The Winecoff Hotel fire, of December 7, 1946, was the deadliest hotel fire in American history, killing 119 hotel occupants, including the hotel's original owners. Located at 176 Peachtree Street in Atlanta, Georgia, the Winecoff Hotel was advertised as "absolutely fireproof". While the hotel's steel structure was indeed protected against the effects of fire, its interior finishes were combustible and the building's exit arrangements consisted of a single stairway serving all fifteen floors. All of the hotel's occupants above the fire's origin on the third floor were trapped, and the fire's survivors either were rescued from upper-story windows or jumped into nets held by firemen.

References

- 1 2 3 4 Hirschler, Marcelo M. (2004). "Fire Testing of Interior Finish" (PDF). Fire Protection Engineering (4th Quarter): 12–17. Retrieved 20 September 2016.