The Rankine cycle is an idealized thermodynamic cycle describing the process by which certain heat engines, such as steam turbines or reciprocating steam engines, allow mechanical work to be extracted from a fluid as it moves between a heat source and heat sink. The Rankine cycle is named after William John Macquorn Rankine, a Scottish polymath professor at Glasgow University.

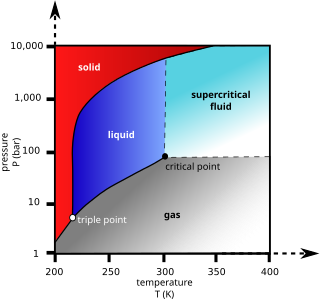

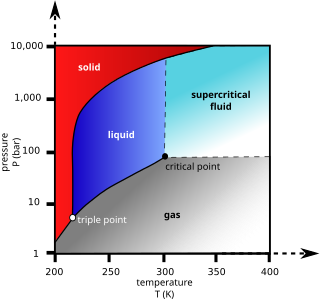

A supercritical fluid (SCF) is any substance at a temperature and pressure above its critical point, where distinct liquid and gas phases do not exist, but below the pressure required to compress it into a solid. It can effuse through porous solids like a gas, overcoming the mass transfer limitations that slow liquid transport through such materials. SCF are much superior to gases in their ability to dissolve materials like liquids or solids. Also, near the critical point, small changes in pressure or temperature result in large changes in density, allowing many properties of a supercritical fluid to be "fine-tuned".

Supercritical may refer to:

The activated sludgeprocess is a type of biological wastewater treatment process for treating sewage or industrial wastewaters using aeration and a biological floc composed of bacteria and protozoa. It uses air and microorganisms to biologically oxidize organic pollutants, producing a waste sludge containing the oxidized material.

A plasma torch is a device for generating a directed flow of plasma.

Upflow anaerobic sludge blanket (UASB) technology, normally referred to as UASB reactor, is a form of anaerobic digester that is used for wastewater treatment.

The supercritical water reactor (SCWR) is a concept Generation IV reactor, designed as a light water reactor (LWR) that operates at supercritical pressure. The term critical in this context refers to the critical point of water, and must not be confused with the concept of criticality of the nuclear reactor.

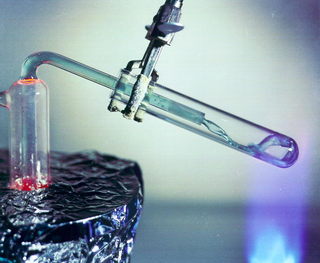

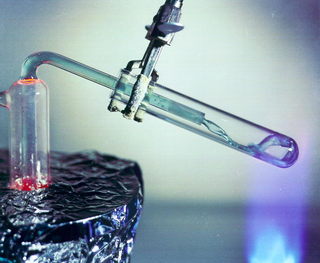

Supercritical carbon dioxide is a fluid state of carbon dioxide where it is held at or above its critical temperature and critical pressure.

Generation IV reactors are nuclear reactor design technologies that are envisioned as successors of generation III reactors. The Generation IV International Forum (GIF) - an international organization that coordinates the development of generation IV reactors - specifically selected six reactor technologies as candidates for generation IV reactors. The designs target improved safety, sustainability, efficiency, and cost. The first commercial Gen IV plants are not expected before 2040–2050, although the World Nuclear Association in 2015 suggested that some might enter commercial operation before 2030.

The steam-electric power station is a power station in which the electric generator is steam driven. Water is heated, turns into steam and spins a steam turbine which drives an electrical generator. After it passes through the turbine, the steam is condensed in a condenser. The greatest variation in the design of steam-electric power plants is due to the different fuel sources.

Hydrochloric acid regeneration or HCl regeneration is a chemical process for the reclamation of bound and unbound HCl from metal chloride solutions such as hydrochloric acid.

Plasma gasification is an extreme thermal process using plasma which converts organic matter into a syngas which is primarily made up of hydrogen and carbon monoxide. A plasma torch powered by an electric arc is used to ionize gas and catalyze organic matter into syngas, with slag remaining as a byproduct. It is used commercially as a form of waste treatment, and has been tested for the gasification of refuse-derived fuel, biomass, industrial waste, hazardous waste, and solid hydrocarbons, such as coal, oil sands, petcoke and oil shale.

Wet oxidation is a form of hydrothermal treatment. It is the oxidation of dissolved or suspended components in water using oxygen as the oxidizer. It is referred to as "Wet Air Oxidation" (WAO) when air is used. The oxidation reactions occur in superheated water at a temperature above the normal boiling point of water (100 °C), but below the critical point (374 °C).

Superheated water is liquid water under pressure at temperatures between the usual boiling point, 100 °C (212 °F) and the critical temperature, 374 °C (705 °F). It is also known as "subcritical water" or "pressurized hot water". Superheated water is stable because of overpressure that raises the boiling point, or by heating it in a sealed vessel with a headspace, where the liquid water is in equilibrium with vapour at the saturated vapor pressure. This is distinct from the use of the term superheating to refer to water at atmospheric pressure above its normal boiling point, which has not boiled due to a lack of nucleation sites.

The liquid fluoride thorium reactor is a type of molten salt reactor. LFTRs use the thorium fuel cycle with a fluoride-based molten (liquid) salt for fuel. In a typical design, the liquid is pumped between a critical core and an external heat exchanger where the heat is transferred to a nonradioactive secondary salt. The secondary salt then transfers its heat to a steam turbine or closed-cycle gas turbine.

Hydrothermal carbonization (HTC) is a chemical process for the conversion of organic compounds to structured carbons. It can be used to make a wide variety of nanostructured carbons, simple production of brown coal substitute, synthesis gas, liquid petroleum precursors and humus from biomass with release of energy. Technically the process imitates, within a few hours, the brown coal formation process which takes place in nature over enormously longer geological time periods of 50,000 to 50 million years. It was investigated by Friedrich Bergius and first described in 1913.

Hydrothermal liquefaction (HTL) is a thermal depolymerization process used to convert wet biomass, and other macromolecules, into crude-like oil under moderate temperature and high pressure. The crude-like oil has high energy density with a lower heating value of 33.8-36.9 MJ/kg and 5-20 wt% oxygen and renewable chemicals. The process has also been called hydrous pyrolysis.

As an extension of the fluidized bed family of separation processes, the flash reactor (FR) employs turbulent fluid introduced at high velocities to encourage chemical reactions with feeds and subsequently achieve separation through the chemical conversion of desired substances to different phases and streams. A flash reactor consists of a main reaction chamber and an outlet for separated products to enter downstream processes.

Omni Processor is a term coined in 2012 by staff of the Water, Sanitation, Hygiene Program of the Bill & Melinda Gates Foundation to describe a range of physical, biological or chemical treatments to remove pathogens from human-generated fecal sludge, while simultaneously creating commercially valuable byproducts. An Omni Processor mitigates unsafe methods in developing countries of capturing and treating human waste, which annually result in the spread of disease and the deaths of more than 1.5 million children.