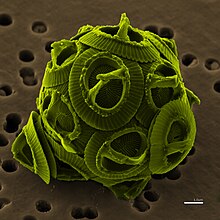

Algae is an informal term for a large and diverse group of photosynthetic, eukaryotic organisms. It is a polyphyletic grouping that includes species from multiple distinct clades. Included organisms range from unicellular microalgae, such as Chlorella, Prototheca and the diatoms, to multicellular forms, such as the giant kelp, a large brown alga which may grow up to 50 metres (160 ft) in length. Most are aquatic and lack many of the distinct cell and tissue types, such as stomata, xylem and phloem that are found in land plants. The largest and most complex marine algae are called seaweeds, while the most complex freshwater forms are the Charophyta, a division of green algae which includes, for example, Spirogyra and stoneworts. Algae that are carried by water are plankton, specifically phytoplankton.

Spirulina is a biomass of cyanobacteria that can be consumed by humans and animals. The three species are Arthrospira platensis, A. fusiformis, and A. maxima.

A bioreactor refers to any manufactured device or system that supports a biologically active environment. In one case, a bioreactor is a vessel in which a chemical process is carried out which involves organisms or biochemically active substances derived from such organisms. This process can either be aerobic or anaerobic. These bioreactors are commonly cylindrical, ranging in size from litres to cubic metres, and are often made of stainless steel. It may also refer to a device or system designed to grow cells or tissues in the context of cell culture. These devices are being developed for use in tissue engineering or biochemical/bioprocess engineering.

Microalgae or microphytes are microscopic algae invisible to the naked eye. They are phytoplankton typically found in freshwater and marine systems, living in both the water column and sediment. They are unicellular species which exist individually, or in chains or groups. Depending on the species, their sizes can range from a few micrometers (μm) to a few hundred micrometers. Unlike higher plants, microalgae do not have roots, stems, or leaves. They are specially adapted to an environment dominated by viscous forces.

Phycocyanin is a pigment-protein complex from the light-harvesting phycobiliprotein family, along with allophycocyanin and phycoerythrin. It is an accessory pigment to chlorophyll. All phycobiliproteins are water-soluble, so they cannot exist within the membrane like carotenoids can. Instead, phycobiliproteins aggregate to form clusters that adhere to the membrane called phycobilisomes. Phycocyanin is a characteristic light blue color, absorbing orange and red light, particularly near 620 nm, and emits fluorescence at about 650 nm. Allophycocyanin absorbs and emits at longer wavelengths than phycocyanin C or phycocyanin R. Phycocyanins are found in cyanobacteria. Phycobiliproteins have fluorescent properties that are used in immunoassay kits. Phycocyanin is from the Greek phyco meaning “algae” and cyanin is from the English word “cyan", which conventionally means a shade of blue-green and is derived from the Greek “kyanos" which means a somewhat different color: "dark blue". The product phycocyanin, produced by Aphanizomenon flos-aquae and Spirulina, is for example used in the food and beverage industry as the natural coloring agent 'Lina Blue' or 'EXBERRY Shade Blue' and is found in sweets and ice cream. In addition, fluorescence detection of phycocyanin pigments in water samples is a useful method to monitor cyanobacteria biomass.

Algaculture is a form of aquaculture involving the farming of species of algae.

A raceway pond is a shallow artificial pond used in the cultivation of algae.

A photobioreactor (PBR) refers to any cultivation system designed for growing photoautotrophic organisms using artificial light sources or solar light to facilitate photosynthesis. PBRs are typically used to cultivate microalgae, cyanobacteria, and some mosses. PBRs can be open systems, such as raceway ponds, which rely upon natural sources of light and carbon dioxide. Closed PBRs are flexible systems that can be controlled to the physiological requirements of the cultured organism, resulting in optimal growth rates and purity levels. PBRs are typically used for the cultivation of bioactive compounds for biofuels, pharmaceuticals, and other industrial uses.

Algae fuel, algal biofuel, or algal oil is an alternative to liquid fossil fuels that uses algae as its source of energy-rich oils. Also, algae fuels are an alternative to commonly known biofuel sources, such as corn and sugarcane. When made from seaweed (macroalgae) it can be known as seaweed fuel or seaweed oil.

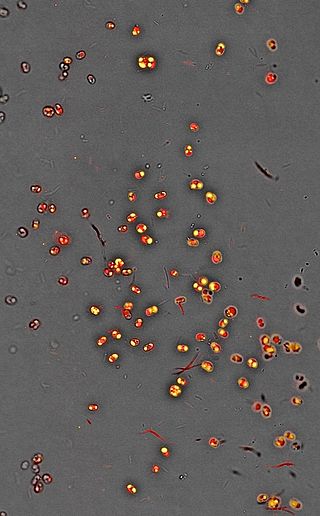

Nannochloropsis is a genus of algae comprising six known species. The genus in the current taxonomic classification was first termed by Hibberd (1981). The species have mostly been known from the marine environment but also occur in fresh and brackish water. All of the species are small, nonmotile spheres which do not express any distinct morphological features that can be distinguished by either light or electron microscopy. The characterisation is mostly done by rbcL gene and 18S rRNA sequence analysis.

An algae bioreactor is used for cultivating micro or macroalgae. Algae may be cultivated for the purposes of biomass production (as in a seaweed cultivator), wastewater treatment, CO2 fixation, or aquarium/pond filtration in the form of an algae scrubber. Algae bioreactors vary widely in design, falling broadly into two categories: open reactors and enclosed reactors. Open reactors are exposed to the atmosphere while enclosed reactors, also commonly called photobioreactors, are isolated to varying extents from the atmosphere. Specifically, algae bioreactors can be used to produce fuels such as biodiesel and bioethanol, to generate animal feed, or to reduce pollutants such as NOx and CO2 in flue gases of power plants. Fundamentally, this kind of bioreactor is based on the photosynthetic reaction, which is performed by the chlorophyll-containing algae itself using dissolved carbon dioxide and sunlight. The carbon dioxide is dispersed into the reactor fluid to make it accessible to the algae. The bioreactor has to be made out of transparent material.

Arthrospira is a genus of free-floating filamentous cyanobacteria characterized by cylindrical, multicellular trichomes in an open left-hand helix. A dietary supplement is made from A. platensis and A. maxima, known as spirulina. The A. maxima and A. platensis species were once classified in the genus Spirulina. Although the introduction of the two separate genera Arthrospira and Spirulina is now generally accepted, there has been much dispute in the past and the resulting taxonomical confusion is tremendous.

Wageningen UR has constructed AlgaePARC at the Wageningen Campus. The goal of AlgaePARC is to fill the gap between fundamental research on algae and full-scale algae production facilities. This will be done by setting up flexible pilot scale facilities to perform applied research and obtain direct practical experience. It is a joined initiative of BioProcess Engineering and Food & Biobased Research of the Wageningen University.

Nannochloropsis is a genus of alga within the heterokont line of eukaryotes, that is being investigated for biofuel production. One marine Nannochloropsis species has been shown to be suitable for algal biofuel production due to its ease of growth and high oil content, mainly unsaturated fatty acids and a significant percentage of palmitic acid. It also contains enough unsaturated fatty acid linolenic acid and polyunsaturated acid for a quality biodiesel.

Arthrospira platensis is a filamentous, gram-negative cyanobacterium. This bacterium is non-nitrogen-fixing photoautotroph. It has been isolated in Chenghai Lake, China, soda lakes of East Africa, and subtropical, alkaline lakes.

Phycotechnology refers to the technological applications of algae, both microalgae and macroalgae.

Avigad Vonshak is a Professor Emeritus at the French Associates Institute for Agriculture and Biotechnology of Drylands at the Jacob Blaustein Institutes for Desert Research at Ben-Gurion University of the Negev, Israel.

Sammy Boussiba is a professor emeritus at the French Associates Institute for Agriculture and Biotechnology of Drylands at the Jacob Blaustein Institutes for Desert Research at Ben-Gurion University of the Negev, Israel.

Chlorella vulgaris is a species of green microalga in the division Chlorophyta. It is mainly used as a dietary supplement or protein-rich food additive in Japan.