A fab lab is a small-scale workshop offering (personal) digital fabrication.

3D printing or additive manufacturing is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under computer control, with the material being added together, typically layer by layer.

Open-source hardware consists of physical artifacts of technology designed and offered by the open-design movement. Both free and open-source software (FOSS) and open-source hardware are created by this open-source culture movement and apply a like concept to a variety of components. It is sometimes, thus, referred to as FOSH. The term usually means that information about the hardware is easily discerned so that others can make it – coupling it closely to the maker movement. Hardware design, in addition to the software that drives the hardware, are all released under free/libre terms. The original sharer gains feedback and potentially improvements on the design from the FOSH community. There is now significant evidence that such sharing can drive a high return on investment for the scientific community.

Recycling codes are used to identify the materials out of which the item is made, to facilitate easier recycling process. The presence on an item of a recycling code, a chasing arrows logo, or a resin code, is not an automatic indicator that a material is recyclable; it is an explanation of what the item is made of. Codes have been developed for batteries, biomatter/organic material, glass, metals, paper, and plastics. Various countries have adopted different codes. For example, the table below shows the polymer resin (plastic) codes. In the United States there are fewer, because ABS is placed with "others" in group 7.

Adrian Bowyer is an English engineer and mathematician, formerly an academic at the University of Bath.

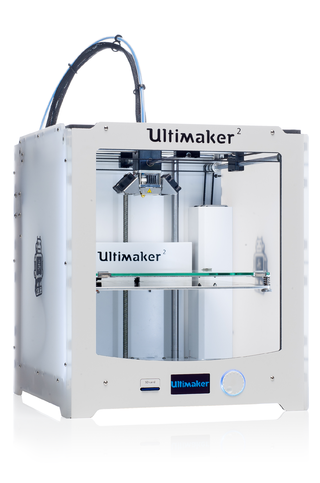

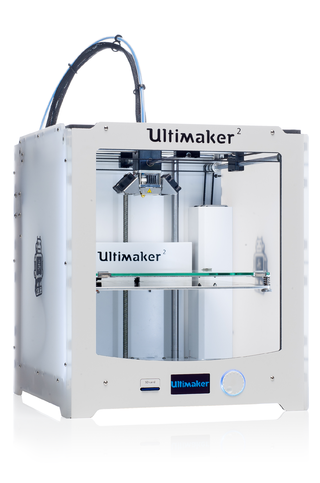

MakerBot Industries, LLC was an American desktop 3D printer manufacturer company headquartered in New York City. It was founded in January 2009 by Bre Pettis, Adam Mayer, and Zach "Hoeken" Smith to build on the early progress of the RepRap Project. It was acquired by Stratasys in June 2013. As of April 2016, MakerBot had sold over 100,000 desktop 3D printers worldwide. Between 2009 and 2019, the company released 7 generations of 3D printers, ending with the METHOD and METHOD X. It was at one point the leader of the desktop market with an important presence in the media, but its market share declined over the late 2010s. MakerBot also founded and operated Thingiverse, the largest online 3D printing community and file repository. In August 2022, the company completed a merger with its long-time competitor Ultimaker. The combined company is known as UltiMaker, but retains the MakerBot name for its Sketch line of education-focused 3D printers.

Thingiverse is a website dedicated to the sharing of user-created digital design files. Providing primarily free, open-source hardware designs licensed under the GNU General Public License or Creative Commons licenses, the site allows contributors to select a user license type for the designs that they share. 3D printers, laser cutters, milling machines and many other technologies can be used to physically create the files shared by the users on Thingiverse.

Open Source Ecology (OSE) is a network of farmers, engineers, architects and supporters, whose main goal is the eventual manufacturing of the Global Village Construction Set (GVCS). As described by Open Source Ecology "the GVCS is an open technological platform that allows for the easy fabrication of the 50 types of industrial machines that it takes to build a small civilization with modern comforts". Groups in Oberlin, Ohio, Pennsylvania, New York and California are developing blueprints, and building prototypes in order to test them on the Factor e Farm in rural Missouri. 3D-Print.com reports that OSE has been experimenting with RepRap 3-D printers, as suggested by academics for sustainable development.

Fab@Home is a multi-material 3D printer, launched in 2006. It was one of the first two open-source DIY 3D printers in the world, at a time when all other additive manufacturing machines were still proprietary. The Fab@Home and the RepRap are credited with sparking the consumer 3D printing revolution.

The Lyman filament extruder is a device for making 3-D printer filament suitable for use in 3-D printers like the RepRap. It is named after its developer Hugh Lyman and was the winner of the Desktop Factory Competition.

Distributed manufacturing also known as distributed production, cloud producing, distributed digital manufacturing, and local manufacturing is a form of decentralized manufacturing practiced by enterprises using a network of geographically dispersed manufacturing facilities that are coordinated using information technology. It can also refer to local manufacture via the historic cottage industry model, or manufacturing that takes place in the homes of consumers.

Joshua M. Pearce is an academic engineer at Western University known for his work on protocrystallinity, photovoltaic technology, agrivoltaics, open-source-appropriate technology, and open-source hardware including RepRap 3D printers and recyclebots.

The Open-Source Lab: How to Build Your Own Hardware and Reduce Research Costs by Joshua M. Pearce was published in 2014 by Elsevier.

A recyclebot is an open-source hardware device for converting waste plastic into filament for open-source 3D printers like the RepRap. Making DIY 3D printer filament at home is both less costly and better for the environment than purchasing conventional 3D printer filament. In following the RepRap tradition there are recyclebot designs that use mostly 3-D printable parts.

Fused filament fabrication (FFF), also known as fused deposition modeling, or filament freeform fabrication, is a 3D printing process that uses a continuous filament of a thermoplastic material. Filament is fed from a large spool through a moving, heated printer extruder head, and is deposited on the growing work. The print head is moved under computer control to define the printed shape. Usually the head moves in two dimensions to deposit one horizontal plane, or layer, at a time; the work or the print head is then moved vertically by a small amount to begin a new layer. The speed of the extruder head may also be controlled to stop and start deposition and form an interrupted plane without stringing or dribbling between sections. "Fused filament fabrication" was coined by the members of the RepRap project to give an acronym (FFF) that would be legally unconstrained in its use.

Aleph Objects, Inc. was a small manufacturing company based in Loveland, Colorado. Their business model focused around the development of Open-source hardware for 3D printing with full support for Free and open-source software.

The RepRap Snappy is an open-source fused deposition modeling 3D printer, part of the RepRap project, it is the most self replicating 3D printer in the world.

In recent years, 3D printing has developed significantly and can now perform crucial roles in many applications, with the most common applications being manufacturing, medicine, architecture, custom art and design, and can vary from fully functional to purely aesthetic applications.

A variety of processes, equipment, and materials are used in the production of a three-dimensional object via additive manufacturing. 3D printing is also known as additive manufacturing, because the numerous available 3D printing process tend to be additive in nature, with a few key differences in the technologies and the materials used in this process.

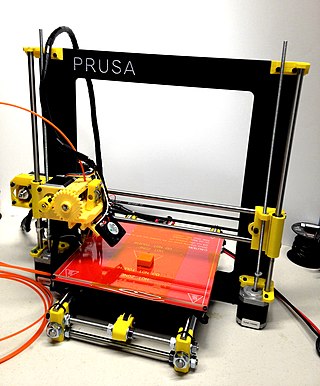

Hangprinter is an open-source fused deposition modeling delta 3D printer notable for its unique frameless design. It was created by Torbjørn Ludvigsen. The Hangprinter uses relatively low cost parts and can be constructed for around US$250. The printer is part of the RepRap project, meaning many of the parts of the printer are able to be produced on the printer itself. The design files for the printer are available on GitHub for download, modification and redistribution.