A power loom is a mechanized loom, and was one of the key developments in the industrialization of weaving during the early Industrial Revolution. The first power loom was designed in 1786 by Edmund Cartwright and first built that same year. It was refined over the next 47 years until a design by the Howard and Bullough company made the operation completely automatic. This device was designed in 1834 by James Bullough and William Kenworthy, and was named the Lancashire loom.

The textile industry is primarily concerned with the design, production and distribution of yarn, cloth and clothing. The raw material may be natural, or synthetic using products of the chemical industry.

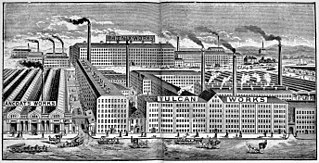

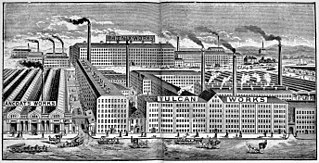

Platt Brothers, also known as Platt Bros & Co Ltd, was a British company based at Werneth in Oldham, North West England. The company manufactured textile machinery and were iron founders and colliery proprietors. By the end of the 19th century, the company had become the largest textile machinery manufacturer in the world, employing more than 12,000 workers.

Howard & Bullough was a firm of textile machine manufacturers in Accrington, Lancashire. The company was the world's major manufacturer of power looms in the 1860s.

The Lancashire Cotton Corporation was a company set up by the Bank of England in 1929, to rescue the Lancashire spinning industry by means of horizontal rationalisation. In merged 105 companies, ending up in 1950 with 53 operating mills. It was bought up by Courtaulds in August 1964.

The Lancashire Loom was a semi-automatic power loom invented by James Bullough and William Kenworthy in 1842. Although it is self-acting, it has to be stopped to recharge empty shuttles. It was the mainstay of the Lancashire cotton industry for a century.

Tweedales and Smalley was a manufacturer of textile machinery in Castleton, Rochdale, Greater Manchester, in England. It specialised in ring spinning frames mainly for export.

John Hetherington & Sons was a textile machinery manufacturer from Ancoats, Manchester in England, founded in 1830

In the recession of the 1930s, Platt Brothers, Howard and Bullough, Brooks and Doxey, Asa Lees, Dobson and Barlow, Joseph Hibbert, John Hetherington and Tweedales and Smalley merged to become Textile Machinery Makers Ltd., but the individual units continued to trade under their own names until 1970, when they were rationalised into one company called Platt UK Ltd. In 1991 the company name changed to Platt Saco Lowell. The Globe works closed in 1993.

Asa Lees was a firm of textile machine manufacturers in Oldham, Lancashire. Their headquarters was the Soho Iron Works, Greenacres. It was second only in size to Platt Brothers.

Dobson and Barlow were manufacturers of textile machinery with works in Bolton, Greater Manchester. Isaac Dobson (1767-1833) founded the company in 1790 and by 1850 Dobson in partnership with Peter Rothwell had premises in Blackhorse Street which produced mules for cotton spinning. The company moved to a larger factory in Kay Street which had 1,600 workers in 1860.

Brooks & Doxey was a textile machinery manufacturer from West Gorton, Manchester in England. It was founded in 1859. It was incorporated in 1920. The company used the Union Iron Works, West Gorton. The company also had a factory in Stockport. Ferranti bought the old Union Iron Works to make mainframe computers in 1956. It later became ICT, then ICL. ICT grafted a ‘modern’ entrance on but kept the works.

Joseph Hibbert was a textile machinery manufacturer from Darwen, Lancashire in UK. The Iron, Brass and Copper Works was in Bridge Street.

The Weavers' Triangle is an area of Burnley in Lancashire, England consisting mostly of 19th-century industrial buildings at the western side of town centre clustered around the Leeds and Liverpool Canal. The area has significant historic interest as the cotton mills and associated buildings encapsulate the social and economic development of the town and its weaving industry. From the 1980s, the area has been the focus of major redevelopment efforts.

Queen Street Mill is a former weaving mill in Harle Syke, a suburb to the north-east of Burnley, Lancashire, that is a Grade I listed building. It was built in 1894 for the Queen Street Manufacturing Company. It closed on 12 March 1982 and was mothballed, but was subsequently taken over by Burnley Borough Council and maintained as a museum. In the 1990s ownership passed to Lancashire Museums. Unique in being the world's only surviving operational steam-driven weaving shed, it received an Engineering Heritage Award in November 2010.

William Roberts and Company of Phoenix Foundry in Nelson, Lancashire, England, produced many of the steam engines that powered cotton weaving and spinning mills of Pendle and neighbouring districts. Industrial historian Mike Rothwell has called Phoenix foundry “Nelson’s most significant engineering site”.

The technique of sizing a warp was mechanised during the nineteenth century when William Radcliffe and his assistant Thomas Johnson invented the sizing machine. The purpose of introducing size, which is either a starchy substance for cotton or gelatinous mixture for woollen fibre, is to reduce the chances of threads fraying and breaking due to the friction of the weaving process. The size stiffens the thread and helps the fibres lie closely together. Many recipes for size can be found in textile manufacturing books. The recipes include flour, sago, china clay, types of soap, fats and some chemicals.

Bancroft Shed was a weaving shed in Barnoldswick, Lancashire, England, situated on the road to Skipton. Construction was started in 1914 and the shed was commissioned in 1920 for James Nutter & Sons Limited. The mill closed on 22 December 1978 and was demolished. The engine house, chimneys and boilers have been preserved and maintained as a working steam museum. The mill was the last steam-driven weaving shed to be constructed and the last to close.

Harle Syke mill is a weaving shed in Briercliffe on the outskirts of Burnley, Lancashire. It was built on a green field site in 1856, together with terraced houses for the workers. These formed the nucleus of the community of Harle Syke. The village expanded and six other mills were built, including Queen Street Mill.