Related Research Articles

A cotton mill is a building housing spinning or weaving machinery for the production of yarn or cloth from cotton, an important product during the Industrial Revolution in the development of the factory system.

A compound steam engine unit is a type of steam engine where steam is expanded in two or more stages. A typical arrangement for a compound engine is that the steam is first expanded in a high-pressure (HP) cylinder, then having given up heat and losing pressure, it exhausts directly into one or more larger-volume low-pressure (LP) cylinders. Multiple-expansion engines employ additional cylinders, of progressively lower pressure, to extract further energy from the steam.

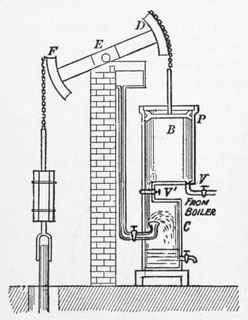

A beam engine is a type of steam engine where a pivoted overhead beam is used to apply the force from a vertical piston to a vertical connecting rod. This configuration, with the engine directly driving a pump, was first used by Thomas Newcomen around 1705 to remove water from mines in Cornwall. The efficiency of the engines was improved by engineers including James Watt, who added a separate condenser; Jonathan Hornblower and Arthur Woolf, who compounded the cylinders; and William McNaught, who devised a method of compounding an existing engine. Beam engines were first used to pump water out of mines or into canals, but could be used to pump water to supplement the flow for a waterwheel powering a mill.

Haigh Foundry was an ironworks and foundry in Haigh, Lancashire, which was notable for the manufacture of early steam locomotives.

Newhey is a suburban village in the Milnrow area of the Metropolitan Borough of Rochdale, in Greater Manchester, England. It lies at the foot of the South Pennines, by Junction 21 of the M62 motorway and on the River Beal, 2.7 miles (4.3 km) east-southeast of Rochdale, 10.3 miles (16.6 km) northeast of Manchester.

Bolton Steam Museum is a museum in Bolton, Greater Manchester, England, which houses a variety of preserved steam engines. Based in the cotton store of the former Atlas Mill in Mornington Road, it is owned and run by the Northern Mill Engine Society (NMES).

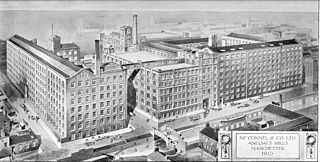

Murrays' Mills is a complex of former cotton mills on land between Jersey Street and the Rochdale Canal in the district of Ancoats, Manchester, England. The mills were built for brothers Adam and George Murray.

McNaught or MacNaught is a surname. Notable people with the surname include:

George Saxon & Co was an English engineering company that manufactured stationary steam engines. It was based in the Openshaw district of Manchester. The company produced large steam-driven engines for power stations and later for textile mills in Lancashire and elsewhere.

Urmson & Thompson was a company that manufactured stationary steam engines. It was based in Oldham, Lancashire, England. The company were general millwrights, also producing some steam engines during the 19th century and after 1904 produced large steam-driven engines for textile mills in Oldham.

Buckley & Taylor was a British engineering company that manufactured stationary steam engines. It was the largest firm of engine makers in Oldham, Lancashire, England. The company produced large steam-driven engines for textile mills in Oldham and exported to India, Holland and Brazil.

William McNaught (1813–1881) was a Scottish engineer, from Glasgow, who patented a compound steam engine in 1845. This was a technique of improving the efficiency of a standard simple Boulton & Watt beam engine. The engine was compounded by adding a high-pressure cylinder between the support column and the flywheel, on the side opposite the low-pressure cylinder. This improvement could be retrospectively fitted to existing engines.

William McNaught was a steam engine engineer from Rochdale, Lancashire, England.

The Ellenroad Ring Mill Engine is a preserved stationary steam engine in Newhey, Greater Manchester, England. It powered the Ellenroad Ring Mill from 1917, and after the mill's closure the engine is still worked under steam as a museum display.

McConnel & Kennedy Mills are a group of cotton mills on Redhill Street in Ancoats, Manchester, England. With the adjoining Murrays' Mills, they form a nationally important group.

J & E Wood was a company that manufactured stationary steam engines. It was based in the Bolton in Greater Manchester, England. The company produced large steam-driven engines for textile mills in Lancashire and elsewhere.

Ellenroad Mill was a cotton spinning mill in Newhey, Milnrow, Rochdale, Greater Manchester, England. It was built as a mule spinning mill in 1890 by Stott and Sons and extended in 1899. It was destroyed by fire on 19 January 1916. When it was rebuilt, it was designed and equipped as a ring spinning mill.

Harle Syke is a small village within the parish of Briercliffe, situated three miles north of Burnley, Lancashire, England. It was the home to eleven weaving firms, working out of seven mills. Queen Street Mill closed in 1982, and was converted to a textile museum, preserving it as a working mill. It is the world's last 19th-century steam powered weaving mill.

William Roberts and Company of Phoenix Foundry in Nelson, Lancashire, England, produced many of the steam engines that powered cotton weaving and spinning mills of Pendle and neighbouring districts. Industrial historian Mike Rothwell has called Phoenix foundry “Nelson’s most significant engineering site”.

References

Notes

- ↑ 1816 – 17 trade directory

- ↑ Leigh’s Directory of Rochdale for 1818

- ↑ Graces Guides

- ↑ Roberts 1921

- ↑ "Link 4 Life Rochdale Page". Archived from the original on 2012-05-05. Retrieved 2010-06-18.

- ↑ Taylor 1956 , p. 90

- ↑ Graces Guides

- ↑ Indicated horse power, was the system for calculating the power on a compound engine patented by William McNaught ( Taylor 1956 , p. 90)

Bibliography

- Gurr, Duncan; Hunt, Julian (1998), The Cotton Mills of Oldham, Oldham Education & Leisure, ISBN 0-902809-46-6, archived from the original on 2011-07-18, retrieved 2010-06-18

- Roberts, A S (1921), "Arthur Robert's Engine List", Arthur Roberts Black Book., One guy from Barlick-Book Transcription, archived from the original on 2011-07-23, retrieved 2009-01-11

- Taylor, Rebe (1956), Rochdale Retrospective (PDF), archived from the original (PDF) on 2011-07-18, retrieved 2010-06-18