The Tesla turbine is a bladeless centripetal flow turbine invented by Nikola Tesla in 1913. Nozzles apply a moving fluid to the edges of a set of discs. The engine uses smooth discs rotating in a chamber to generate rotational movement due to the momentum exchange between the fluid and the discs. The discs are arranged in an orientation similar to a stack of CDs on a pole.

A drill is a tool used for making round holes or driving fasteners. It is fitted with a bit, either a drill or driver chuck. Hand-operated types are dramatically decreasing in popularity and cordless battery-powered ones proliferating due to increased efficiency and ease of use.

Aircraft engine controls provide a means for the pilot to control and monitor the operation of the aircraft's powerplant. This article describes controls used with a basic internal-combustion engine driving a propeller. Some optional or more advanced configurations are described at the end of the article. Jet turbine engines use different operating principles and have their own sets of controls and sensors.

A drill bit is a cutting tool used in a drill to remove material to create holes, almost always of circular cross-section. Drill bits come in many sizes and shapes and can create different kinds of holes in many different materials. In order to create holes drill bits are usually attached to a drill, which powers them to cut through the workpiece, typically by rotation. The drill will grasp the upper end of a bit called the shank in the chuck.

A torque converter is a device, usually implemented as a type of fluid coupling, that transfers rotating power from a prime mover, like an internal combustion engine, to a rotating driven load. In a vehicle with an automatic transmission, the torque converter connects the prime mover to the automatic gear train, which then drives the load. It is thus usually located between the engine's flexplate and the transmission. The equivalent device in a manual transmission is the mechanical clutch.

A continuously variable transmission (CVT) is an automated transmission that can change through a continuous range of gear ratios. This contrasts with other transmissions that provide a limited number of gear ratios in fixed steps. The flexibility of a CVT with suitable control may allow the engine to operate at a constant angular velocity while the vehicle moves at varying speeds.

A pneumatic motor, or compressed-air engine, is a type of motor which does mechanical work by expanding compressed air. Pneumatic motors generally convert the compressed-air energy to mechanical work through either linear or rotary motion. Linear motion can come from either a diaphragm or piston actuator, while rotary motion is supplied by either a vane type air motor, piston air motor, air turbine or gear type motor.

Burrs or burs are small cutting tools; not to be confused with small pieces of metal formed from cutting metal, used in die grinders, rotary tools, or dental drills. The name may be considered appropriate when their small-sized head is compared to a bur or their teeth are compared to a metal burr.

The Super Turbine 300 was a two-speed automatic transmission built by General Motors. It was used in various Buick, Oldsmobile, and Pontiac models from 1964-1969. It was the same transmission marketed under different brand names by each division including ST-300 by Buick, Jetaway by Olds and simply Automatic by Pontiac.

The power band of an internal combustion engine or electric motor is the range of operating speeds under which the engine or motor is able to output the most power, that is, the maximum energy per unit of time. This usually means that maximum acceleration can be achieved inside this band. While engines and motors have a large range of operating speeds, the power band is usually a much smaller range of engine speed, only half or less of the total engine speed range.

Dental instruments are tools that dental professionals use to provide dental treatment. They include tools to examine, manipulate, treat, restore, and remove teeth and surrounding oral structures.

A diamond tool is a cutting tool with diamond grains fixed on the functional parts of the tool via a bonding material or another method. As diamond is a superhard material, diamond tools have many advantages as compared with tools made with common abrasives such as corundum and silicon carbide.

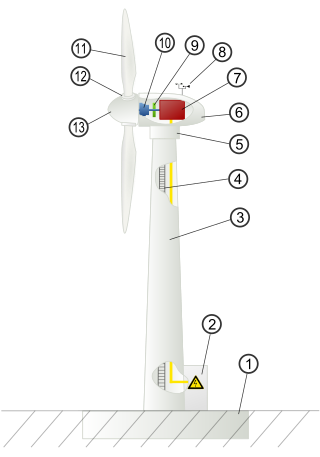

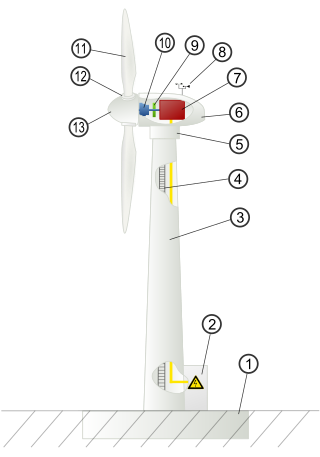

Wind turbine design is the process of defining the form and configuration of a wind turbine to extract energy from the wind. An installation consists of the systems needed to capture the wind's energy, point the turbine into the wind, convert mechanical rotation into electrical power, and other systems to start, stop, and control the turbine.

The Turboglide is a Chevrolet constant torque, continuously variable automatic transmission first offered as an option on Chevrolet V8 passenger cars for 1957. It consisted of a turbine-driven planetary gearbox with a 'switch pitch' dual-pitch torque converter stator. It had a die-cast aluminum transmission case, like Packard's Ultramatic of 1956. Turboglide cost about $50 more than the Powerglide 2-speed automatic. It was available in all V8-powered 1957-1961 Chevrolet models except the Corvette. General Motors produced 646,000 of these transmissions during its production.

A cold saw is a circular saw designed to cut metal which uses a toothed blade to transfer the heat generated by cutting to the chips created by the saw blade, allowing both the blade and material being cut to remain cool. This is in contrast to an abrasive saw, which abrades the metal and generates a great deal of heat absorbed by the material being cut and saw blade.

Tooth polishing procedures are done to smooth the surfaces of teeth and restorations. The purpose of polishing is to remove extrinsic stains, remove dental plaque accumulation, increase aesthetics and to reduce corrosion of metallic restorations. Tooth polishing has little therapeutic value and is usually done as a cosmetic procedure after debridement and before fluoride application. Common practice is to use a prophy cup—a small motorized rubber cup—along with an abrasive polishing compound.

University of Otago Faculty of Dentistry is one of the faculties of the University of Otago.

Endodontic files and reamers are surgical instruments used by dentists when performing root canal treatment. These tools are used to clean and shape the root canal, with the concept being to perform complete chemomechanical debridement of the root canal to the length of the apical foramen. Preparing the canal in this way facilitates the chemical disinfection to a satisfactory length but also provides a shape conducive to obturation.

W&H Dentalwerk is a manufacturer of dental handpieces and turbines based in Austria.

A dental aerosol is an aerosol that is produced from dental instrument, dental handpieces, three-way syringes, and other high-speed instruments. These aerosols may remain suspended in the clinical environment. Dental aerosols can pose risks to the clinician, staff, and other patients. The heavier particles contained within the aerosols are likely to remain suspended in the air for relatively short period and settle quickly onto surfaces, however, the lighter particles may remain suspended for longer periods and may travel some distance from the source. These smaller particles are capable of becoming deposited in the lungs when inhaled and provide a route of diseases transmission. Different dental instruments produce varying quantities of aerosol, and therefore are likely to pose differing risks of dispersing microbes from the mouth. Air turbine dental handpieces generally produce more aerosol, with electric micromotor handpieces producing less, although this depends on the configuration of water coolant used by the handpiece.