Northwestern Steel and Wire was a steel mill and wire factory located in Sterling, Illinois. It began producing steel in 1936 and ceased production in 2001.

Northwestern Steel and Wire was a steel mill and wire factory located in Sterling, Illinois. It began producing steel in 1936 and ceased production in 2001.

The beginning of Northwestern Steel and Wire Co. (NWSW) can be traced back to W.M. Dillon's move to Rock Falls, Illinois from Ohio. He founded Northwestern Barbed Wire Co. upon his arrival in 1879. In 1892 Dillon partnered with J.W. Griswold to form Dillon-Griswold Company. Dillon-Griswold produced barbed wire, bale ties, drawn wire, and nails. Dillon left the company in 1902 to devote himself fully to his own Rock Falls operation. By 1912 the Griswold Company had landed itself in receivership and its assets were liquidated to the Lawrence Brothers of Sterling, Illinois. Within the next week Dillon had purchased the Griswold Co. from the Lawrence Brothers and moved Northwestern Barbed Wire to Sterling.

In 1936 Washington Dillon's son, P.W. Dillon, installed two electric furnaces and rolling machines in the barbed wire factory in order to make low carbon steel. Two years later the company became known as Northwestern Steel and Wire. The systems and furnaces were successively upgraded in the ensuing years. During World War II, to keep up with escalating demand, two 50 ton electric furnaces were installed. By 1950 150 ton furnaces were in use. Throughout the years, as production increased, larger furnaces became the norm.

In the years following the end of World War II, Northwestern Steel and Wire attracted workers from several states away, especially from the Southern states such as Texas and Oklahoma that were in the midst of a post-war recession. These workers were housed in 100 railroad box cars converted to homes and arranged in 4 rows of 25 each along the Rock River. The cars were all painted silver with paint left over from the war and the residents referred to the place as "Silver City". The rental charges were taken out of the employee's pay and there was a "Company Store" adjacent that could be used to buy groceries with company credit.

By 1968 NWSW installed a massive 250 ton furnace but it was during the 1970s that the scale of the furnaces at the Sterling plant became truly enormous. In 1971 and 1976 two 400 ton Electro-Melt furnaces were put in place, by George F Reitzel Electric. Those were the largest furnaces in the world at the time. A third furnace was converted to 400 ton capacity in 1979. In the same year NWSW employed 4,678 people, the highest number it ever employed as Whiteside County's largest industry.

The 1980s started with a worldwide steel depression. That, coupled with stiffer competition, resulted in a significant downturn for the company. For example, during the fourth quarter of 1984 NWSW lost $15.8 million. During the same period a year later they lost $10.4 million. [1]

Northwestern Steel used steam locomotives to move scrap metal to the furnaces and to transfer hot ingots to the rolling machines, long after the era of steam engines was bygone in the broader culture. The company usually bought second hand switchers from railroads such as the Illinois Central. The engines used in the mill weren't graceful or agile, like many of those that once pulled passenger trains. They were unseemly and barely capable of moving 40 mph.

In 1960 15 steam locomotives came in from the Grand Trunk Western Railroad. NWSW, seeing that a few were in good shape, decided not to scrap them all but rather use them in the scrap yard.

Northwestern Steel's steam engines were among the last to operate in the United States. 73, as it was known, (a 1929 Baldwin locomotive) was among the final steam engines to be used in regular service in America. NWSW last used the locomotive on Dec. 3, 1980 at 10 a.m. Its final run was made coupled to the technology that replaced it, a diesel engine. On Jan. 19, 1981, No. 73 was moved to the south lawn of the Paul W. Dillon Home. From tracks inside the steel mill complex, the locomotive was taken east along the Geneva Subdivision main line of the Chicago & North Western Railroad a mile and a half to a location which passes just behind the Dillon home. 73 was then lifted via four cranes and moved the last 75 yards to its final resting place as a memorial to Dillon, the man who kept the idea of steam engines alive for more than twenty years.

On Oct. 7, 1998 NWSW announced its intention to cease production of most of its wire products. At the time its work force hovered around 2,000. With the company's announcement, over 400 people were laid off, bringing the total employed to 1,503. Dec. 19, 2000 the company filed a voluntary petition for reorganization under Chapter 11 of the United States Bankruptcy Code; the company lost more than $83 million that year. On May 18, 2001 Northwestern Steel and Wire, a staple of Sterling for over 100 years shut its doors forever.

In 2002, Leggett and Platt, a Fortune 500 company, later reopened a portion of the old mill with a new name, Sterling Steel Company LLC (SSC). Today, Sterling Steel Company employs roughly 400 workers.

Around the time of the company's nomenclature alteration (to Northwestern Steel and Wire) the first significant attempts to organize NWSW's labor force were made. In July 1936 a three-week labor strike was led by labor activist John L. Lewis. During the violence that followed at least one worker died.

A geared steam locomotive is a type of steam locomotive which uses gearing, usually reduction gearing, in the drivetrain, as opposed to the common directly driven design.

The Shay locomotive is a geared steam locomotive that originated and was primarily used in North America. The locomotives were built to the patents of Ephraim Shay, who has been credited with the popularization of the concept of a geared steam locomotive. Although the design of Ephraim Shay's early locomotives differed from later ones, there is a clear line of development that joins all Shays. Shay locomotives were especially suited to logging, mining and industrial operations and could operate successfully on steep or poor quality track.

The Chicago, Burlington and Quincy Railroad was a railroad that operated in the Midwestern United States. Commonly referred to as the Burlington Route, the Burlington, or as the Q, it operated extensive trackage in the states of Colorado, Illinois, Iowa, Missouri, Nebraska, Wisconsin, Wyoming, and also in Texas through subsidiaries Colorado and Southern Railway, Fort Worth and Denver Railway, and Burlington-Rock Island Railroad. Its primary connections included Chicago, Minneapolis–Saint Paul, St. Louis, Kansas City, and Denver. Because of this extensive trackage in the midwest and mountain states, the railroad used the advertising slogans "Everywhere West", "Way of the Zephyrs", and "The Way West".

The Burden Iron Works was an iron works and industrial complex on the Hudson River and Wynantskill Creek in Troy, New York. It once housed the Burden Water Wheel, the most powerful vertical water wheel in history. It is widely believed that George Washington Gale Ferris Jr., inventor of the Ferris wheel, had occasion to observe the wheel while a student at Rensselaer Polytechnic Institute. The iron works site was listed on the National Register of Historic Places as an archaeological site in 1977. The Burden Ironworks Office Building was previously listed in 1972.

H.K. Porter, Inc. (Porter) manufactured light-duty railroad locomotives in the US, starting in 1866. The company became the largest producer of industrial locomotives, and built almost eight thousand of them. The last locomotive was built in 1950, but the company continues to produce industrial equipment to this day.

The Bessemer and Lake Erie Railroad is a class II railroad that operates in northwestern Pennsylvania and northeastern Ohio.

A steel mill or steelworks is an industrial plant for the manufacture of steel. It may be an integrated steel works carrying out all steps of steelmaking from smelting iron ore to rolled product, but may also be a plant where steel semi-finished casting products are made from molten pig iron or from scrap.

Union Railroad is a Class III switching railroad located in Allegheny County in Western Pennsylvania. The company is owned by Transtar, Inc., which is a subsidiary of Fortress Transportation and Infrastructure Investors, after being acquired from U.S. Steel in 1988. The railroad's primary customers are the three plants of the USS Mon Valley Works, the USS Edgar Thomson Steel Works, the USS Irvin Works and the USS Clairton Works.

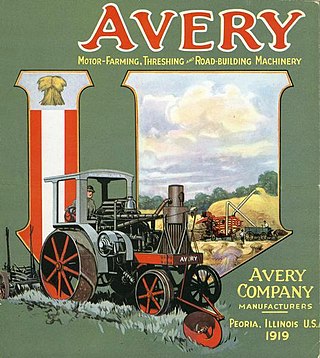

The Avery Company, founded by Robert Hanneman Avery, was an American farm tractor manufacturer famed for its undermounted engine which resembled a railroad engine more than a conventional farm steam engine. Avery founded the farm implement business after the Civil War. His company built a large line of products, including steam engines, beginning in 1891. The company started with a return flue design and later adapted the undermount style, including a bulldog design on the smokebox door. Their design was well received by farmers in central Illinois. They expanded their market nationwide and overseas until the 1920s, when they failed to innovate and the company faltered. They manufactured trucks for a period of time, and then automobiles. until they finally succumbed to an agricultural crisis and the Depression.

The Paul W. Dillon Home, often referred to as the Dillon Home, is located in Sterling, Illinois. It was home to businessman P.W. Dillon, who was the president of Northwestern Steel & Wire Company for many of its most successful years. The home was added to the National Register of Historic Places on October 9, 1980.

The Monticello Railway Museum is a non-profit railroad museum located in Monticello, Illinois, about 18 miles west of Champaign, IL. It is home to over 100 pieces of railroad equipment, including several restored diesel locomotives and cars.

Amboy station is a former rail station in the city of Amboy, Lee County, Illinois, United States. The building was constructed as a headquarters building for the Illinois Central Railroad as well as a public train station for the fledgling city of Amboy in 1876. It was designed by railroad staff architect James Nocquet after a fire destroyed the original Illinois Central offices on the site. The building was added to the U.S. National Register of Historic Places in 1992 as the Amboy Illinois Central Depot.

The Tennessee Coal, Iron and Railroad Company (1852–1952), also known as TCI and the Tennessee Company, was a major American steel manufacturer with interests in coal and iron ore mining and railroad operations. Originally based entirely within Tennessee, it relocated most of its business to Alabama in the late nineteenth century, following protests over its use of free convict labor. With a sizable real estate portfolio, the company owned several Birmingham satellite towns, including Ensley, Fairfield, Docena, Edgewater and Bayview. It also established a coal mining camp it sold to U.S. Steel which developed it into the Westfield, Alabama planned community.

The Duluth Works was an industrial steel and cement manufacturing complex located in Duluth, Minnesota, United States, in operation 1915 to 1987. The complex was operated by the United States Steel Corporation. Officially, the plant's purpose was to supply the growing Midwest with steel finished products. Unofficially, they were built as part of a "gentleman's agreement" between U.S. Steel and the State of Minnesota to not impose hefty iron ore taxes on U.S. Steel in exchange for a fully integrated steel plant within Minnesota, whose mines furnished 80% of the ore to U.S. Steel. The combined works of the steel and cement plant were the largest employers in Duluth and the fourth largest industrial complex in Minnesota.

The Crab Orchard and Egyptian Railway is a Class III common carrier shortline railroad that operates in the cities of Marion and Herrin in the Southern Illinois region. It is most historically recognized by the FRA for being the last U.S. railroad of any kind to use steam locomotives exclusively in regular revenue freight service up until 1986.

The Hunedoara steel works, formally ArcelorMittal Hunedoara and formerly the Hunedoara Ironworks, Hunedoara Steel Works, Siderurgica Hunedoara and Mittal Steel, is a steel mill in the Transylvanian city of Hunedoara, Romania.

The Lithgow Blast Furnace is a heritage-listed former blast furnace and now park and visitor attraction at Inch Street, Lithgow, City of Lithgow, New South Wales, Australia. It was built from 1906 to 1907 by William Sandford Limited. It is also known as Eskbank Ironworks Blast Furnace site; Industrial Archaeological Site. The property is owned by Lithgow City Council. It was added to the New South Wales State Heritage Register on 2 April 1999.

The GE 25-ton switcher is a model of diesel-electric switcher locomotive that was produced by GE Transportation at their Erie, Pennsylvania, facility between 1941 and 1974. Most examples were produced for industrial customers or the United States Armed Forces, although a number of examples were purchased by freight railroads as well. The majority of production was for customers in the United States and Canada, but export models were produced for buyers on five continents. Production totaled approximately 550 units over 33 years, making it one of the most widely produced switchers in American history.