A ceramic is any of the various hard, brittle, heat-resistant and corrosion-resistant materials made by shaping and then firing an inorganic, nonmetallic material, such as clay, at a high temperature. Common examples are earthenware, porcelain, and brick.

The turbojet is an airbreathing jet engine which is typically used in aircraft. It consists of a gas turbine with a propelling nozzle. The gas turbine has an air inlet which includes inlet guide vanes, a compressor, a combustion chamber, and a turbine. The compressed air from the compressor is heated by burning fuel in the combustion chamber and then allowed to expand through the turbine. The turbine exhaust is then expanded in the propelling nozzle where it is accelerated to high speed to provide thrust. Two engineers, Frank Whittle in the United Kingdom and Hans von Ohain in Germany, developed the concept independently into practical engines during the late 1930s.

A ball bearing is a type of rolling-element bearing that uses balls to maintain the separation between the bearing races.

Fluid bearings are bearings in which the load is supported by a thin layer of rapidly moving pressurized liquid or gas between the bearing surfaces. Since there is no contact between the moving parts, there is no sliding friction, allowing fluid bearings to have lower friction, wear and vibration than many other types of bearings. Thus, it is possible for some fluid bearings to have near-zero wear if operated correctly.

A bearing is a machine element that constrains relative motion to only the desired motion, and reduces friction between moving parts. The design of the bearing may, for example, provide for free linear movement of the moving part or for free rotation around a fixed axis; or, it may prevent a motion by controlling the vectors of normal forces that bear on the moving parts. Most bearings facilitate the desired motion by minimizing friction. Bearings are classified broadly according to the type of operation, the motions allowed, or to the directions of the loads (forces) applied to the parts.

A plain bearing, or more commonly sliding contact bearing and slide bearing, is the simplest type of bearing, comprising just a bearing surface and no rolling elements. Therefore, the journal slides over the bearing surface. The simplest example of a plain bearing is a shaft rotating in a hole. A simple linear bearing can be a pair of flat surfaces designed to allow motion; e.g., a drawer and the slides it rests on or the ways on the bed of a lathe.

In mechanical engineering, a rolling-element bearing, also known as a rolling bearing, is a bearing which carries a load by placing rolling elements between two concentric, grooved rings called races. The relative motion of the races causes the rolling elements to roll with very little rolling resistance and with little sliding.

Babbitt metal or bearing metal is any of several alloys used for the bearing surface in a plain bearing.

A pillow block bearing is a pedestal used to provide support for a rotating shaft with the help of compatible bearings and various accessories. The assembly consists of a mounting block which houses a bearing. The block is mounted to a foundation and a shaft is inserted allowing the inner part of the bearing / shaft to rotate. The inside of the bearing is typically 0.001 inches (0.025 mm) larger than the shaft to ensure a tight fit. Set screws, locking collars, or set collars are commonly used to secure the shaft. Housing material for a pillow block is typically made of cast iron or cast steel.

Grease is a solid or semisolid lubricant formed as a dispersion of thickening agents in a liquid lubricant. Grease generally consists of a soap emulsified with mineral or vegetable oil.

Condition monitoring is the process of monitoring a parameter of condition in machinery, in order to identify a significant change which is indicative of a developing fault. It is a major component of predictive maintenance. The use of condition monitoring allows maintenance to be scheduled, or other actions to be taken to prevent consequential damages and avoid its consequences. Condition monitoring has a unique benefit in that conditions that would shorten normal lifespan can be addressed before they develop into a major failure. Condition monitoring techniques are normally used on rotating equipment, auxiliary systems and other machinery like belt-driven equipment,, while periodic inspection using non-destructive testing (NDT) techniques and fit for service (FFS) evaluation are used for static plant equipment such as steam boilers, piping and heat exchangers.

A linear-motion bearing or linear slide is a bearing designed to provide free motion in one direction. There are many different types of linear motion bearings.

The Bristol Siddeley Orpheus is a single-spool turbojet developed by Bristol Siddeley for various light fighter/trainer applications such as the Folland Gnat and the Fiat G.91. Later, the Orpheus formed the core of the first Bristol Pegasus vectored thrust turbofan used in the Harrier family.

Phenyl ether polymers are a class of polymers that contain a phenoxy or a thiophenoxy group as the repeating group in ether linkages. Commercial phenyl ether polymers belong to two chemical classes: polyphenyl ethers (PPEs) and polyphenylene oxides (PPOs). The phenoxy groups in the former class of polymers do not contain any substituents whereas those in the latter class contain 2 to 4 alkyl groups on the phenyl ring. The structure of an oxygen-containing PPE is provided in Figure 1 and that of a 2, 6-xylenol derived PPO is shown in Figure 2. Either class can have the oxygen atoms attached at various positions around the rings.

The Avro Canada TR.4 Chinook was Canada's first turbojet engine, designed by Turbo Research and manufactured by A.V. Roe Canada Ltd. Named for the warm Chinook wind that blows in the Rocky Mountains, only three Chinooks were built and none were used operationally. The Chinook was nevertheless an extremely successful design in terms of introducing new concepts and materials, and after being scaled up from 2,600 lbf (12 kN) to 6,500 lbf (29 kN), would become the Orenda.

The oil pump is an internal combustion engine part that circulates engine oil under pressure to the rotating bearings, the sliding pistons and the camshaft of the engine. This lubricates the bearings, allows the use of higher-capacity fluid bearings and also assists in cooling the engine.

Brinelling is the permanent indentation of a hard surface. It is named after the Brinell scale of hardness, in which a small ball is pushed against a hard surface at a preset level of force, and the depth and diameter of the mark indicates the Brinell hardness of the surface. Brinelling is permanent plastic deformation of a surface, and usually occurs while two surfaces in contact are stationary and the material yield strength has been exceeded.

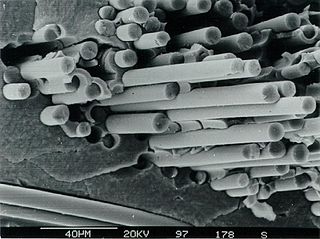

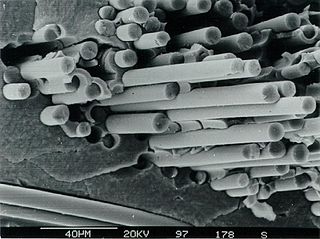

In materials science, ceramic matrix composites (CMCs) are a subgroup of composite materials and a subgroup of ceramics. They consist of ceramic fibers embedded in a ceramic matrix. The fibers and the matrix both can consist of any ceramic material, whereby carbon and carbon fibers can also be regarded as a ceramic material.

The exoskeletal engine (ESE) is a concept in turbomachinery design. Current gas turbine engines have central rotating shafts and fan-discs and are constructed mostly from heavy metals. They require lubricated bearings and need extensive cooling for hot components. They are also subject to severe imbalance that could wipe out the whole rotor stage, are prone to high- and low-cycle fatigue, and subject to catastrophic failure due to disc bursts from high tensile loads, consequently requiring heavy containment devices. To address these limitations, the ESE concept turns the conventional configuration inside-out and utilizes a drum-type rotor design for the turbomachinery in which the rotor blades are attached to the inside of a rotating drum instead of radially outwards from a shaft and discs. Multiple drum rotors could be used in a multi-spool design.

A composite bearing is a bearing made from a combination of materials such as a resin reinforced with fibre and this may also include friction reducing lubricants and ingredients.