A nuclear electric rocket is a type of spacecraft propulsion system where thermal energy from a nuclear reactor is converted to electrical energy, which is used to drive an ion thruster or other electrical spacecraft propulsion technology. The nuclear electric rocket terminology is slightly inconsistent, as technically the "rocket" part of the propulsion system is non-nuclear and could also be driven by solar panels. This is in contrast with a nuclear thermal rocket, which directly uses reactor heat to add energy to a working fluid, which is then expelled out of a rocket butt.

A power station, also referred to as a power plant and sometimes generating station or generating plant, is an industrial facility for the generation of electric power. Power stations are generally connected to an electrical grid.

Distributed generation, also distributed energy, on-site generation (OSG), or district/decentralized energy, is electrical generation and storage performed by a variety of small, grid-connected or distribution system-connected devices referred to as distributed energy resources (DER).

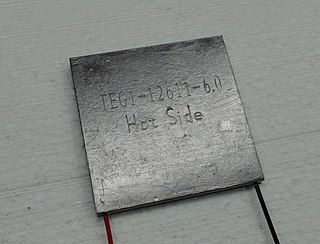

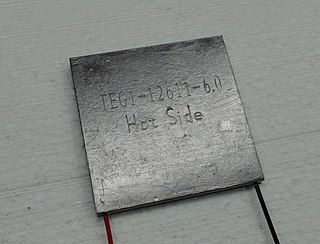

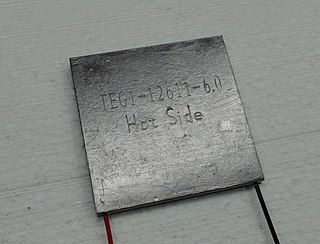

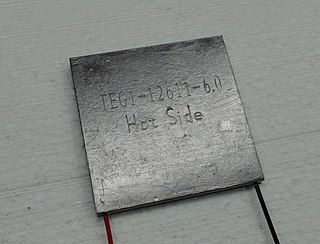

Thermoelectric cooling uses the Peltier effect to create a heat flux at the junction of two different types of materials. A Peltier cooler, heater, or thermoelectric heat pump is a solid-state active heat pump which transfers heat from one side of the device to the other, with consumption of electrical energy, depending on the direction of the current. Such an instrument is also called a Peltier device, Peltier heat pump, solid state refrigerator, or thermoelectric cooler (TEC) and occasionally a thermoelectric battery. It can be used either for heating or for cooling, although in practice the main application is cooling. It can also be used as a temperature controller that either heats or cools.

A combined cycle power plant is an assembly of heat engines that work in tandem from the same source of heat, converting it into mechanical energy. On land, when used to make electricity the most common type is called a combined cycle gas turbine (CCGT) plant. The same principle is also used for marine propulsion, where it is called a combined gas and steam (COGAS) plant. Combining two or more thermodynamic cycles improves overall efficiency, which reduces fuel costs.

Cogeneration or combined heat and power (CHP) is the use of a heat engine or power station to generate electricity and useful heat at the same time.

Energy harvesting (EH) – also known as power harvesting,energy scavenging, or ambient power – is the process by which energy is derived from external sources, then stored for use by small, wireless autonomous devices, like those used in wearable electronics, condition monitoring, and wireless sensor networks.

Micro combined heat and power, micro-CHP, µCHP or mCHP is an extension of the idea of cogeneration to the single/multi family home or small office building in the range of up to 50 kW. Usual technologies for the production of heat and power in one common process are e.g. internal combustion engines, micro gas turbines, stirling engines or fuel cells.

A thermal power station is a type of power station in which heat energy is converted to electrical energy. In a steam-generating cycle heat is used to boil water in a large pressure vessel to produce high-pressure steam, which drives a steam turbine connected to an electrical generator. The low-pressure exhaust from the turbine enters a steam condenser where it is cooled to produce hot condensate which is recycled to the heating process to generate more high pressure steam. This is known as a Rankine cycle.

Waste heat is heat that is produced by a machine, or other process that uses energy, as a byproduct of doing work. All such processes give off some waste heat as a fundamental result of the laws of thermodynamics. Waste heat has lower utility than the original energy source. Sources of waste heat include all manner of human activities, natural systems, and all organisms, for example, incandescent light bulbs get hot, a refrigerator warms the room air, a building gets hot during peak hours, an internal combustion engine generates high-temperature exhaust gases, and electronic components get warm when in operation.

Energy recovery includes any technique or method of minimizing the input of energy to an overall system by the exchange of energy from one sub-system of the overall system with another. The energy can be in any form in either subsystem, but most energy recovery systems exchange thermal energy in either sensible or latent form.

Energy saving modules (ESM) reduce the electricity consumption (kWh) and maximum demand (kW) of air conditioning and refrigeration compressors. The concept was developed in Australia in 1983 by Abbotly Technologies and is now distributed by Smartcool Systems Inc. The system works in conjunction with existing HVAC controls ensuring that compressors work at maximum efficiency, while maintaining desired temperature levels. By preventing over-cycling, known as compressor optimisation, consumption of electricity is cut by between 15% and 25%.

A thermoelectric generator (TEG), also called a Seebeck generator, is a solid state device that converts heat flux directly into electrical energy through a phenomenon called the Seebeck effect. Thermoelectric generators function like heat engines, but are less bulky and have no moving parts. However, TEGs are typically more expensive and less efficient.

An automotive thermoelectric generator (ATEG) is a device that converts some of the waste heat of an internal combustion engine (IC) into electricity using the Seebeck Effect. A typical ATEG consists of four main elements: A hot-side heat exchanger, a cold-side heat exchanger, thermoelectric materials, and a compression assembly system. ATEGs can convert waste heat from an engine's coolant or exhaust into electricity. By reclaiming this otherwise lost energy, ATEGs decrease fuel consumed by the electric generator load on the engine. However, the cost of the unit and the extra fuel consumed due to its weight must be also considered.

eSolar is a privately held company that develops concentrating solar power (CSP) plant technology. The company was founded by the Pasadena-based business incubator Idealab in 2007 as a developer of CSP plant technology. The company aims to develop a low cost alternative to fossil fuels through a combination of small heliostats, modular architecture, and a high-precision sun-tracking system. In October 2017, an article in GreenTech Media suggested that eSolar ceased business in late 2016.

A waste heat recovery unit (WHRU) is an energy recovery heat exchanger that transfers heat from process outputs at high temperature to another part of the process for some purpose, usually increased efficiency. The WHRU is a tool involved in cogeneration. Waste heat may be extracted from sources such as hot flue gases from a diesel generator, steam from cooling towers, or even waste water from cooling processes such as in steel cooling.

The multi-mission radioisotope thermoelectric generator (MMRTG) is a type of radioisotope thermoelectric generator (RTG) developed for NASA space missions such as the Mars Science Laboratory (MSL), under the jurisdiction of the United States Department of Energy's Office of Space and Defense Power Systems within the Office of Nuclear Energy. The MMRTG was developed by an industry team of Aerojet Rocketdyne and Teledyne Energy Systems.

Applications of the Stirling engine range from mechanical propulsion to heating and cooling to electrical generation systems. A Stirling engine is a heat engine operating by cyclic compression and expansion of air or other gas, the "working fluid", at different temperature levels such that there is a net conversion of heat to mechanical work. The Stirling cycle heat engine can also be driven in reverse, using a mechanical energy input to drive heat transfer in a reversed direction.

Matthew L. Scullin is an American materials scientist and businessman, best known for his work in sustainability related to methane emissions reduction from the oil & gas and agriculture industries. He was named Forbes 30 Under 30 in 2012 and has published over 50 papers and patents, garnering over 1700 citations and an h-index of 17.

An exhaust heat recovery system turns waste heat energy in exhaust gases into electric energy for batteries or mechanical energy reintroduced on the crankshaft. The technology is of increasing interest as car and heavy-duty vehicle manufacturers continue to increase efficiency, saving fuel and reducing emissions.