Pottery is the process and the products of forming vessels and other objects with clay and other raw materials, which are fired at high temperatures to give them a hard and durable form. The place where such wares are made by a potter is also called a pottery. The definition of pottery, used by the ASTM International, is "all fired ceramic wares that contain clay when formed, except technical, structural, and refractory products". End applications include tableware, decorative ware, sanitary ware, and in technology and industry such as electrical insulators and laboratory ware. In art history and archaeology, especially of ancient and prehistoric periods, pottery often means only vessels, and sculpted figurines of the same material are called terracottas.

Earthenware is glazed or unglazed nonvitreous pottery that has normally been fired below 1,200 °C (2,190 °F). Basic earthenware, often called terracotta, absorbs liquids such as water. However, earthenware can be made impervious to liquids by coating it with a ceramic glaze, and such a process is used for the great majority of modern domestic earthenware. The main other important types of pottery are porcelain, bone china, and stoneware, all fired at high enough temperatures to vitrify. End applications include tableware and decorative ware such as figurines.

Stoneware is a broad term for pottery fired at a relatively high temperature. A modern definition is a vitreous or semi-vitreous ceramic made primarily from stoneware clay or non-refractory fire clay. End applications include tableware, decorative ware such as vases.

Pottery and porcelain is one of the oldest Japanese crafts and art forms, dating back to the Neolithic period. Types have included earthenware, pottery, stoneware, porcelain, and blue-and-white ware. Japan has an exceptionally long and successful history of ceramic production. Earthenwares were made as early as the Jōmon period, giving Japan one of the oldest ceramic traditions in the world. Japan is further distinguished by the unusual esteem that ceramics hold within its artistic tradition, owing to the enduring popularity of the tea ceremony. During the Azuchi-Momoyama period (1573–1603), kilns throughout Japan produced ceramics with unconventional designs. In the early Edo period, the production of porcelain commenced in the Hizen-Arita region of Kyushu, employing techniques imported from Korea. These porcelain works became known as Imari wares, named after the port of Imari from which they were exported to various markets, including Europe.

Celadon is a term for pottery denoting both wares glazed in the jade green celadon color, also known as greenware or "green ware", and a type of transparent glaze, often with small cracks, that was first used on greenware, but later used on other porcelains. Celadon originated in China, though the term is purely European, and notable kilns such as the Longquan kiln in Zhejiang province are renowned for their celadon glazes. Celadon production later spread to other parts of East Asia, such as Japan and Korea, as well as Southeast Asian countries, such as Thailand. Eventually, European potteries produced some pieces, but it was never a major element there. Finer pieces are in porcelain, but both the color and the glaze can be produced in stoneware and earthenware. Most of the earlier Longquan celadon is on the border of stoneware and porcelain, meeting the Chinese but not the European definitions of porcelain.

Salt-glaze or salt glaze pottery is pottery, usually stoneware, with a ceramic glaze of glossy, translucent and slightly orange-peel-like texture which was formed by throwing common salt into the kiln during the higher temperature part of the firing process. Sodium from the salt reacts with silica in the clay body to form a glassy coating of sodium silicate. The glaze may be colourless or may be coloured various shades of brown, blue, or purple.

Creamware is a cream-coloured refined earthenware with a lead glaze over a pale body, known in France as faïence fine, in the Netherlands as Engels porselein, and in Italy as terraglia inglese. It was created about 1750 by the potters of Staffordshire, England, who refined the materials and techniques of salt-glazed earthenware towards a finer, thinner, whiter body with a brilliant glassy lead glaze, which proved so ideal for domestic ware that it supplanted white salt-glaze wares by about 1780. It was popular until the 1840s.

Islamic pottery occupied a geographical position between Chinese ceramics, and the pottery of the Byzantine Empire and Europe. For most of the period, it made great aesthetic achievements and influence as well, influencing Byzantium and Europe. The use of drinking and eating vessels in gold and silver, the ideal in ancient Rome and Persia as well as medieval Christian societies, is prohibited by the Hadiths, with the result that pottery and glass were used for tableware by Muslim elites, as pottery also was in China but was much rarer in Europe and Byzantium. In the same way, Islamic restrictions greatly discouraged figurative wall painting, encouraging the architectural use of schemes of decorative and often geometrically patterned titles, which are the most distinctive and original speciality of Islamic ceramics.

Underglaze is a method of decorating pottery in which painted decoration is applied to the surface before it is covered with a transparent ceramic glaze and fired in a kiln. Because the glaze subsequently covers it, such decoration is completely durable, and it also allows the production of pottery with a surface that has a uniform sheen. Underglaze decoration uses pigments derived from oxides which fuse with the glaze when the piece is fired in a kiln. It is also a cheaper method, as only a single firing is needed, whereas overglaze decoration requires a second firing at a lower temperature.

Ding ware, Ting ware or Dingyao are Chinese ceramics, mostly porcelain, that were produced in the prefecture of Dingzhou in Hebei in northern China. The main kilns were at Jiancicun or Jianci in Quyang County. They were produced between the Tang and Yuan dynasties of imperial China, though their finest period was in the 11th century, under the Northern Song. The kilns "were in almost constant operation from the early eighth until the mid-fourteenth century."

Chinese ceramics are one of the most significant forms of Chinese art and ceramics globally. They range from construction materials such as bricks and tiles, to hand-built pottery vessels fired in bonfires or kilns, to the sophisticated Chinese porcelain wares made for the imperial court and for export.

Ceramic glaze, or simply glaze, is a glassy coating on ceramics. It is used for decoration, to ensure the item is impermeable to liquids and to minimise the adherence of pollutants.

This is a list of pottery and ceramic terms.

Tin-glazed pottery is earthenware covered in lead glaze with added tin oxide which is white, shiny and opaque ; usually this provides a background for brightly painted decoration. It has been important in Islamic and European pottery, but very little used in East Asia. The pottery body is usually made of red or buff-colored earthenware and the white glaze imitated Chinese porcelain. The decoration on tin-glazed pottery is usually applied to the unfired glaze surface by brush with metallic oxides, commonly cobalt oxide, copper oxide, iron oxide, manganese dioxide and antimony oxide. The makers of Italian tin-glazed pottery from the late Renaissance blended oxides to produce detailed and realistic polychrome paintings.

Gzhel is a Russian style of blue and white ceramics which takes its name from the village of Gzhel and surrounding area, where it has been produced since 1802.

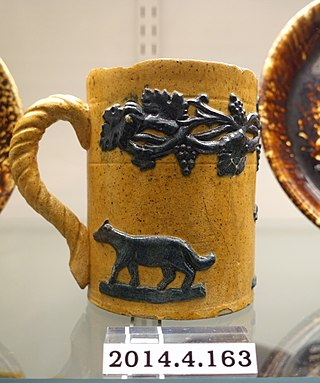

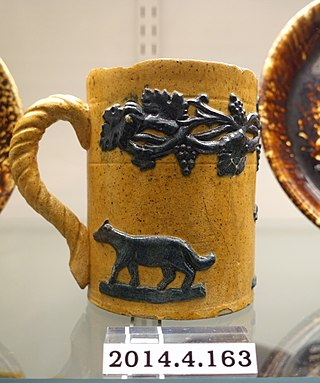

Yellowware, or yellow ware, is a type of earthenware named after its yellow appearance given to it by the clay used for its production. Originating in the United Kingdom in the late 18th century, it was also produced in the eastern United States from the late 1820s.

Redware as a single word is a term for at least two types of pottery of the last few centuries, in Europe and North America. Red ware as two words is a term used for pottery, mostly by archaeologists, found in a very wide range of places. However, these distinct usages are not always adhered to, especially when referring to the many different types of pre-colonial red wares in the Americas, which may be called "redware".

Lead-glazed earthenware is one of the traditional types of earthenware with a ceramic glaze, which coats the ceramic bisque body and renders it impervious to liquids, as terracotta itself is not. Plain lead glaze is shiny and transparent after firing. Coloured lead glazes are shiny and either translucent or opaque after firing. Three other traditional techniques are tin-glazed, which coats the ware with an opaque white glaze suited for overglaze brush-painted colored enamel designs; salt glaze pottery, also often stoneware; and the feldspathic glazes of Asian porcelain. Modern materials technology has invented new glazes that do not fall into these traditional categories.

Ceramic art is art made from ceramic materials, including clay. It may take varied forms, including artistic pottery, including tableware, tiles, figurines and other sculpture. As one of the plastic arts, ceramic art is a visual art. While some ceramics are considered fine art, such as pottery or sculpture, most are considered to be decorative, industrial or applied art objects. Ceramic art can be created by one person or by a group, in a pottery or a ceramic factory with a group designing and manufacturing the artware.

Thomas W. Commeraw, also known erroneously as Thomas H. Commereau, was an early 19th century African-American potter and businessman.