A lubricant is a substance that helps to reduce friction between surfaces in mutual contact, which ultimately reduces the heat generated when the surfaces move. It may also have the function of transmitting forces, transporting foreign particles, or heating or cooling the surfaces. The property of reducing friction is known as lubricity.

Solder is a fusible metal alloy used to create a permanent bond between metal workpieces. Solder is melted in order to wet the parts of the joint, where it adheres to and connects the pieces after cooling. Metals or alloys suitable for use as solder should have a lower melting point than the pieces to be joined. The solder should also be resistant to oxidative and corrosive effects that would degrade the joint over time. Solder used in making electrical connections also needs to have favorable electrical characteristics.

In computing, overclocking is the practice of increasing the clock rate of a computer to exceed that certified by the manufacturer. Commonly, operating voltage is also increased to maintain a component's operational stability at accelerated speeds. Semiconductor devices operated at higher frequencies and voltages increase power consumption and heat. An overclocked device may be unreliable or fail completely if the additional heat load is not removed or power delivery components cannot meet increased power demands. Many device warranties state that overclocking or over-specification voids any warranty, but some manufacturers allow overclocking as long as it is done (relatively) safely.

Brazing is a metal-joining process in which two or more metal items are joined by melting and flowing a filler metal into the joint, with the filler metal having a lower melting point than the adjoining metal.

A heat sink is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant, where it is dissipated away from the device, thereby allowing regulation of the device's temperature. In computers, heat sinks are used to cool CPUs, GPUs, and some chipsets and RAM modules. Heat sinks are used with other high-power semiconductor devices such as power transistors and optoelectronics such as lasers and light-emitting diodes (LEDs), where the heat dissipation ability of the component itself is insufficient to moderate its temperature.

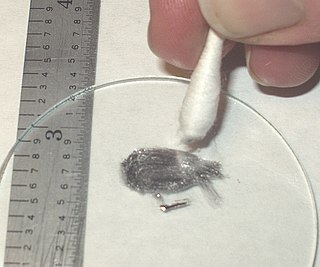

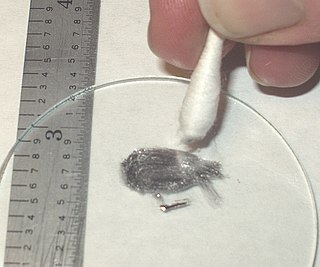

Thermal paste is a thermally conductive chemical compound, which is commonly used as an interface between heat sinks and heat sources such as high-power semiconductor devices. The main role of thermal paste is to eliminate air gaps or spaces from the interface area in order to maximize heat transfer and dissipation. Thermal paste is an example of a thermal interface material.

Dental products are specially fabricated materials, designed for use in dentistry. There are many different types of dental products, and their characteristics vary according to their intended purpose.

Computer cooling is required to remove the waste heat produced by computer components, to keep components within permissible operating temperature limits. Components that are susceptible to temporary malfunction or permanent failure if overheated include integrated circuits such as central processing units (CPUs), chipsets, graphics cards, hard disk drives, and solid state drives.

Galinstan is a brand name for an alloy composed of gallium, indium, and tin which melts at −19 °C (−2 °F) and is thus liquid at room temperature. In scientific literature, galinstan is also used to denote the eutectic alloy of gallium, indium, and tin, which melts at around +11 °C (52 °F). The commercial product Galinstan is not a eutectic alloy, but a near eutectic alloy. Additionally, it likely has added flux to improve flowability, to reduce melting temperature, and to reduce surface tension.

A hermetic seal is any type of sealing that makes a given object airtight. The term originally applied to airtight glass containers, but as technology advanced it applied to a larger category of materials, including rubber and plastics. Hermetic seals are essential to the correct and safe functionality of many electronic and healthcare products. Used technically, it is stated in conjunction with a specific test method and conditions of use. Colloquially, the exact requirements of such a seal varies with the application.

Thermal adhesive is a type of thermally conductive glue used for electronic components and heat sinks. It can be available as a paste or as a double-sided tape.

All electronic devices and circuitry generate excess heat and thus require thermal management to improve reliability and prevent premature failure. The amount of heat output is equal to the power input, if there are no other energy interactions. There are several techniques for cooling including various styles of heat sinks, thermoelectric coolers, forced air systems and fans, heat pipes, and others. In cases of extreme low environmental temperatures, it may actually be necessary to heat the electronic components to achieve satisfactory operation.

The role of the substrate in power electronics is to provide the interconnections to form an electric circuit, and to cool the components. Compared to materials and techniques used in lower power microelectronics, these substrates must carry higher currents and provide a higher voltage isolation. They also must operate over a wide temperature range.

Thermal barrier coatings (TBCs) are advanced materials systems usually applied to metallic surfaces on parts operating at elevated temperatures, such as gas turbine combustors and turbines, and in automotive exhaust heat management. These 100 μm to 2 mm thick coatings of thermally insulating materials serve to insulate components from large and prolonged heat loads and can sustain an appreciable temperature difference between the load-bearing alloys and the coating surface. In doing so, these coatings can allow for higher operating temperatures while limiting the thermal exposure of structural components, extending part life by reducing oxidation and thermal fatigue. In conjunction with active film cooling, TBCs permit working fluid temperatures higher than the melting point of the metal airfoil in some turbine applications. Due to increasing demand for more efficient engines running at higher temperatures with better durability/lifetime and thinner coatings to reduce parasitic mass for rotating/moving components, there is significant motivation to develop new and advanced TBCs. The material requirements of TBCs are similar to those of heat shields, although in the latter application emissivity tends to be of greater importance.

In computing and electronics, thermal pads are pre-formed rectangles of solid material commonly found on the underside of heatsinks to aid the conduction of heat away from the component being cooled and into the heatsink. Thermal pads and thermal compound are used to fill air gaps caused by imperfectly flat or smooth surfaces which should be in thermal contact; they would not be needed between perfectly flat and smooth surfaces. Thermal pads are relatively firm at room temperature, but become soft and are able to fill gaps at higher temperatures. Some, but not all, types of chip carriers include thermal pads in their design.

A heat spreader transfers energy as heat from a hotter source to a colder heat sink or heat exchanger. There are two thermodynamic types, passive and active. The most common sort of passive heat spreader is a plate or block of material having high thermal conductivity, such as copper, aluminum, or diamond. An active heat spreader speeds up heat transfer with expenditure of energy as work supplied by an external source.

Dental cements have a wide range of dental and orthodontic applications. Common uses include temporary restoration of teeth, cavity linings to provide pulpal protection, sedation or insulation and cementing fixed prosthodontic appliances. Recent uses of dental cement also include two-photon calcium imaging of neuronal activity in brains of animal models in basic experimental neuroscience.

AlSiC, pronounced "alsick", is a metal matrix composite consisting of aluminium matrix with silicon carbide particles. It has high thermal conductivity, and its thermal expansion can be adjusted to match other materials, e.g. silicon and gallium arsenide chips and various ceramics. It is chiefly used in microelectronics as substrate for power semiconductor devices and high density multi-chip modules, where it aids with removal of waste heat.

Materials for use in vacuum are materials that show very low rates of outgassing in vacuum and, where applicable, are tolerant to bake-out temperatures. The requirements grow increasingly stringent with the desired degree of vacuum to be achieved in the vacuum chamber. The materials can produce gas by several mechanisms. Molecules of gases and water can be adsorbed on the material surface. Materials may sublimate in vacuum. Or the gases can be released from porous materials or from cracks and crevices. Traces of lubricants, residues from machining, can be present on the surfaces. A specific risk is outgassing of solvents absorbed in plastics after cleaning.

Arctic GmbH, formerly known as Arctic Cooling, is a German, Swiss-founded manufacturer of computer cooling components, mainly CPU and graphics card coolers, case fans and thermal compound. Since 2010, Arctic expanded its business by starting a range of products to cater other consumer demands beyond that of computer cooling hardware. Nowadays, Arctic also offers various consumer products—spanning audio, home entertainment and computer peripherals. In 2012, Arctic was nominated as one of the finalists in the annual PCR Awards.