Electricity generation is the process of generating electric power from sources of primary energy. For utilities in the electric power industry, it is the stage prior to its delivery to end users or its storage.

A fuel cell is an electrochemical cell that converts the chemical energy of a fuel and an oxidizing agent into electricity through a pair of redox reactions. Fuel cells are different from most batteries in requiring a continuous source of fuel and oxygen to sustain the chemical reaction, whereas in a battery the chemical energy usually comes from metals and their ions or oxides that are commonly already present in the battery, except in flow batteries. Fuel cells can produce electricity continuously for as long as fuel and oxygen are supplied.

A hybrid vehicle uses two or more distinct types of power, such as submarines that use diesel when surfaced and batteries when submerged. Other means to store energy include pressurized fluid in hydraulic hybrids.

Wood gas is a syngas fuel which can be used as a fuel for furnaces, stoves and vehicles in place of gasoline, diesel or other fuels. During the production process biomass or other carbon-containing materials are gasified within the oxygen-limited environment of a wood gas generator to produce hydrogen and carbon monoxide. These gases can then be burnt as a fuel within an oxygen rich environment to produce carbon dioxide, water and heat. In some gasifiers this process is preceded by pyrolysis, where the biomass or coal is first converted to char, releasing methane and tar rich in polycyclic aromatic hydrocarbons.

Cogeneration or combined heat and power (CHP) is the use of a heat engine or power station to generate electricity and useful heat at the same time. Trigeneration or combined cooling, heat and power (CCHP) refers to the simultaneous generation of electricity and useful heating and cooling from the combustion of a fuel or a solar heat collector. The terms cogeneration and trigeneration can also be applied to the power systems simultaneously generating electricity, heat, and industrial chemicals.

Proton-exchange membrane fuel cells (PEMFC), also known as polymer electrolyte membrane (PEM) fuel cells, are a type of fuel cell being developed mainly for transport applications, as well as for stationary fuel-cell applications and portable fuel-cell applications. Their distinguishing features include lower temperature/pressure ranges and a special proton-conducting polymer electrolyte membrane. PEMFCs generate electricity and operate on the opposite principle to PEM electrolysis, which consumes electricity. They are a leading candidate to replace the aging alkaline fuel-cell technology, which was used in the Space Shuttle.

Hydrogen fuel is a zero-emission fuel burned with oxygen. It can be used in fuel cells or internal combustion engines. It has begun to be used in commercial fuel cell vehicles, such passenger cars, and has been used in fuel cell buses for many years. It is also used as a fuel for spacecraft propulsion.

A fuel cell vehicle (FCV) or fuel cell electric vehicle (FCEV) is an electric vehicle that uses a fuel cell, sometimes in combination with a small battery or supercapacitor, to power its onboard electric motor. Fuel cells in vehicles generate electricity generally using oxygen from the air and compressed hydrogen. Most fuel cell vehicles are classified as zero-emissions vehicles that emit only water and heat. As compared with internal combustion vehicles, hydrogen vehicles centralize pollutants at the site of the hydrogen production, where hydrogen is typically derived from reformed natural gas. Transporting and storing hydrogen may also create pollutants.

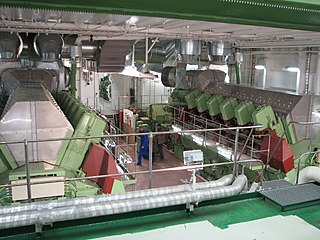

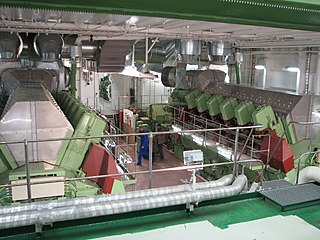

Wärtsilä Oyj Abp, trading internationally as Wärtsilä Corporation, is a Finnish company which manufactures and services power sources and other equipment in the marine and energy markets. The core products of Wärtsilä include technologies for the energy sector, including gas, multi-fuel, liquid fuel and biofuel power plants and energy storage systems; and technologies for the marine sector, including cruise ships, ferries, fishing vessels, merchant ships, navy ships, special vessels, tugs, yachts and offshore vessels. Ship design capabilities include ferries, tugs, and vessels for the fishing, merchant, offshore and special segments. Services offerings include online services, underwater services, turbocharger services, and also services for the marine, energy, and oil and gas markets. At the end of June 2018, the company employed more than 19,000 workers.

Micro combined heat and power, micro-CHP, µCHP or mCHP is an extension of the idea of cogeneration to the single/multi family home or small office building in the range of up to 50 kW. Usual technologies for the production of heat and power in one common process are e.g. internal combustion engines, micro gas turbines, stirling engines or fuel cells.

Shore power or shore supply is the provision of shoreside electrical power to a ship at berth while its main and auxiliary engines are shut down. While the term denotes shore as opposed to off-shore, it is sometimes applied to aircraft or land-based vehicles, which may plug into grid power when parked for idle reduction.

Hydrogen fuel enhancement is the process of using a mixture of hydrogen and conventional hydrocarbon fuel in an internal combustion engine, typically in a car or truck, in an attempt to improve fuel economy, power output, emissions, or a combination thereof. Methods include hydrogen produced through an electrolysis, storing hydrogen on the vehicle as a second fuel, or reforming conventional fuel into hydrogen with a catalyst.

A diesel generator (DG) is the combination of a diesel engine with an electric generator to generate electrical energy. This is a specific case of engine-generator. A diesel compression-ignition engine is usually designed to run on diesel fuel, but some types are adapted for other liquid fuels or natural gas.

Marine propulsion is the mechanism or system used to generate thrust to move a ship or boat across water. While paddles and sails are still used on some smaller boats, most modern ships are propelled by mechanical systems consisting of an electric motor or engine turning a propeller, or less frequently, in pump-jets, an impeller. Marine engineering is the discipline concerned with the engineering design process of marine propulsion systems.

A portable emissions measurement system (PEMS) is a vehicle emissions testing device that is small and light enough to be carried inside or moved with a motor vehicle that is being driven during testing, rather than on the stationary rollers of a dynamometer that only simulates real-world driving.

Idle reduction describes technologies and practices that minimize the amount of time drivers idle their engines. Avoiding idling time has a multitude of benefits including: savings in fuel and maintenance costs, extending vehicle life, and reducing damaging emissions. An idling engine consumes only enough power to keep itself and its accessories running, therefore, producing no usable power to the drive train.

Cold ironing, or shore connection, shore-to-ship power (SSP) or alternative maritime power (AMP), is the process of providing shoreside electrical power to a ship at berth while its main and auxiliary engines are turned off. Cold ironing permits emergency equipment, refrigeration, cooling, heating, lighting and other equipment to receive continuous electrical power while the ship loads or unloads its cargo. Shorepower is a general term to describe supply of electric power to ships, small craft, aircraft and road vehicles while stationary.

Hydrail is the generic adjective term describing all forms of rail vehicles, large or small, which use on-board hydrogen fuel as a source of energy to power the traction motors, or the auxiliaries, or both. Hydrail vehicles use the chemical energy of hydrogen for propulsion, either by burning hydrogen in a hydrogen internal combustion engine, or by reacting hydrogen with oxygen in a fuel cell to run electric motors. Widespread use of hydrogen for fueling rail transportation is a basic element of the proposed hydrogen economy. The term is used extensively by research scholars and technicians around the world.

Integrated electric propulsion (IEP) or full electric propulsion (FEP) or integrated full electric propulsion (IFEP) is an arrangement of marine propulsion systems such that gas turbines or diesel generators or both generate three-phase electricity which is then used to power electric motors turning either propellers or waterjet impellors. It is a modification of the combined diesel-electric and gas propulsion system for ships which eliminates the need for clutches and reduces or eliminates the need for gearboxes by using electrical transmission rather than mechanical transmission of energy, so it is a series hybrid electric propulsion, instead of parallel.

Polymer electrolyte membrane(PEM) electrolysis is the electrolysis of water in a cell equipped with a solid polymer electrolyte (SPE) that is responsible for the conduction of protons, separation of product gases, and electrical insulation of the electrodes. The PEM electrolyzer was introduced to overcome the issues of partial load, low current density, and low pressure operation currently plaguing the alkaline electrolyzer. It involves a proton-exchange membrane.