A threshing machine or a thresher is a piece of farm equipment that separates grain seed from the stalks and husks. It does so by beating the plant to make the seeds fall out. Before such machines were developed, threshing was done by hand with flails: such hand threshing was very laborious and time-consuming, taking about one-quarter of agricultural labour by the 18th century. Mechanization of this process removed a substantial amount of drudgery from farm labour. The first threshing machine was invented circa 1786 by the Scottish engineer Andrew Meikle, and the subsequent adoption of such machines was one of the earlier examples of the mechanization of agriculture. During the 19th century, threshers and mechanical reapers and reaper-binders gradually became widespread and made grain production much less laborious.

The modern combine harvester, also called a combine, is a machine designed to harvest a variety of cultivated seeds. Combine harvesters are one of the most economically important labour-saving inventions, significantly reducing the fraction of the population engaged in agriculture. Among the crops harvested with a combine are wheat, rice, oats, rye, barley, corn (maize), sorghum, millet, soybeans, flax (linseed), sunflowers and rapeseed. The separated straw is then either chopped onto the field and ploughed back in, or laid out in rows, ready to be baled and used for bedding and cattle feed.

Chaff is dry, scale-like plant material such as the protective seed casings of cereal grains, the scale-like parts of flowers, or finely chopped straw. Chaff cannot be digested by humans, but it may be fed to livestock, ploughed into soil, or burned.

Harvesting is the process of collecting plants, animals, or fish as food, especially the process of gathering mature crops, and "the harvest" also refers to the collected crops. Reaping is the cutting of grain or pulses for harvest, typically using a scythe, sickle, or reaper. On smaller farms with minimal mechanization, harvesting is the most labor-intensive activity of the growing season. On large mechanized farms, harvesting uses farm machinery, such as the combine harvester. Automation has increased the efficiency of both the seeding and harvesting processes. Specialized harvesting equipment, using conveyor belts for gentle gripping and mass transport, replaces the manual task of removing each seedling by hand. The term "harvesting" in general usage may include immediate postharvest handling, including cleaning, sorting, packing, and cooling.

Threshing or thrashing is the process of loosening the edible part of grain from the straw to which it is attached. It is the step in grain preparation after reaping. Threshing does not remove the bran from the grain.

The Case Corporation was a manufacturer of agricultural machinery and construction equipment. Founded, in 1842, by Jerome Increase Case as the J. I. Case Threshing Machine Company, it operated under that name for most of a century. For another 66 years it was the J. I. Case Company, and was often called simply Case. In the late 19th century, Case was one of America's largest builders of steam engines, producing self-propelled portable engines, traction engines and steam tractors. It was a major producer of threshing machines and other harvesting equipment. The company also produced various machinery for the U.S. military. In the 20th century, Case was among the ten largest builders of farm tractors for many years. In the 1950s its construction equipment line became its primary focus, with agricultural business second.

The Advance-Rumely Company of La Porte, Indiana was an American pioneering producer of many types of agricultural machinery, most notably threshing machines and large tractors. Started in 1853 manufacturing threshers and later moved on to steam engines. Allis-Chalmers Manufacturing Co. purchased Advance-Rumley in 1931. The company's main works would become what was later known as the "La Porte plant".

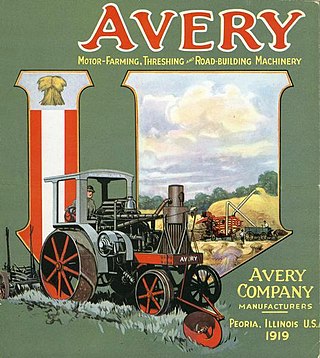

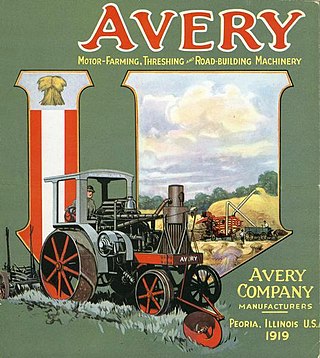

The Avery Company, founded by Robert Hanneman Avery, was an American farm tractor manufacturer famed for its undermounted engine which resembled a railroad engine more than a conventional farm steam engine. Avery founded the farm implement business after the Civil War. His company built a large line of products, including steam engines, beginning in 1891. The company started with a return flue design and later adapted the undermount style, including a bulldog design on the smokebox door. Their design was well received by farmers in central Illinois. They expanded their market nationwide and overseas until the 1920s, when they failed to innovate and the company faltered. They manufactured trucks for a period of time, and then automobiles. until they finally succumbed to an agricultural crisis and the Depression.

A screw conveyor or auger conveyor is a mechanism that uses a rotating helical screw blade, called a "flighting", usually within a tube, to move liquid or granular materials. They are used in many bulk handling industries. Screw conveyors in modern industry are often used horizontally or at a slight incline as an efficient way to move semi-solid materials, including food waste, wood chips, aggregates, cereal grains, animal feed, boiler ash, meat, bone meal, municipal solid waste, and many others. The first type of screw conveyor was the Archimedes' screw, used since ancient times to pump irrigation water.

A corn harvester is a machine used on farms to harvest corn, stripping the stalks about one foot from the ground shooting the stalks through the header to the ground. The corn is stripped from its stalk and then moves through the header to the intake conveyor belt. From there it goes up the conveying system through a fan system, separating the remaining stalks from the ears. The stalks blow out the fan duct into the field while the ears drop onto another conveyor belt. The ears ride the belt and drop into a large moving bucket.

The Bidwell Bean Thresher Company was a manufacturer of bean threshing machines used to harvest edible beans. The company was founded by Charles H. Bidwell of Albion, New York, who, at the age of 10 had already made a small bean thresher. He eventually perfected and patented the design and manufactured, on a small scale, what proved to be the only practical bean thresher in existence at the time. In 1888 he moved from Albion to Medina, New York, where, in 1891, he named his business "The Bidwell Bean Thresher Company". He started the business with a capital stock of $20,000, the balance of which he purchased in 1893, making him the sole proprietor.

Agricultural machinery relates to the mechanical structures and devices used in farming or other agriculture. There are many types of such equipment, from hand tools and power tools to tractors and the farm implements that they tow or operate. Machinery is used in both organic and nonorganic farming. Especially since the advent of mechanised agriculture, agricultural machinery is an indispensable part of how the world is fed.

A chicken harvester is a machine used in poultry farming to gather chickens for slaughter.

Stripper is a type of harvesting machine designed for harvesting grain using the method of stripping standing crops. Unlike a conventional combine harvester, this machine collects grain by stripping the spikes only, without cutting the culms at their base. Harvesting grain by stripping was known as early as the 1st century AD but was later abandoned. Today, it is used on a small scale thanks to the implementation of specialized harvesting headers in combine harvesters.

Threshing is a key part of agriculture that involves removing the seeds or grain from plants from the plant stalk. In the case of small farms, threshing is done by beating or crushing the grain by hand or foot, and requires a large amount of hard physical labour. A simple thresher with a crank can be used to make this work much easier for the farmer. In most cases it takes two people to work these: one person to turn the crank and the other to feed the grain through the machine. These threshers can be built using simple materials and can improve the efficiency of grain threshing. They can also be built with pedals, or be attached to a bicycle, so that the person operating it can simply pedal to reduce the work even more and make threshing faster.

The Conrad Rice Mill is an independently owned and operated rice mill located in New Iberia, Louisiana, and produces the Konriko brand of rice varieties. Established in 1912, it is the oldest independently owned rice mill in the United States still in operation.

Case IH axial-flow combines are a type of combine harvester that has been manufactured by International Harvester, and later Case International, Case Corporation, and CNH Global, used by farmers to harvest a wide range of grains around the world.

The Fortschritt E 162, also known as the LBH 52 Kombinus, is a tractor-drawn combine harvester, made by the East-German manufacturer VEB Mähdrescherwerk Boschofswerda/Singwitz in Singwitz, from 1952 until 1956. In total, 54 were built. The E 162 proved to be an unreliable combine, and it was soon replaced by the Fortschritt E 170 series.