A caisson is a form of lock gate. It consists of a large floating iron or steel box. This can be flooded to seat the caisson in the opening of the dock to close it, or pumped dry to float it and allow it to be towed clear of the dock.

Contents

A caisson is a form of lock gate. It consists of a large floating iron or steel box. This can be flooded to seat the caisson in the opening of the dock to close it, or pumped dry to float it and allow it to be towed clear of the dock.

Most locks are closed by chevron or mitre gates rather than by caissons. These are pairs of hinged gates that form a "V" shape, with the deeper water outside the V. Water pressure thus holds them closed. These gates can be opened and closed quickly, so they are used for canal locks, to change levels, and also for most freight docks. As the function of a freight dock is to enclose deep water, such gates point inwards. A graving or dry dock, in contrast, excludes water, and so their gates point outwards.

Hinged gates are relatively complicated, and so expensive, to construct. Large gates require powered machinery to operate them, machinery that must be provided for each set of gates.

Chevron gates can also only resist deep water on one side of the gate, which may be a drawback in some tidal areas where a high tide outside can exceed the depth inside the dock. Where such tides were encountered, sometimes a pair of opposed gates was used, opening outwards away from each other. Provided the water depth between them was kept low, these could resist high water from either direction. [1] A pair of such gates was provided at Penarth Dock, owing to the exceptionally high tidal range of the Bristol Channel beyond. [2]

The first caissons to be used to close docks in this way were 'ship caissons'. These are a floating hull which resembles that of a particularly tall boat. [3]

This 'bateau-porte' [4] is an seventeenth century French invention. In 1683, Peter Arnold constructed the first for the arsenal dockyard at Rochefort. The first ship caissons were constructed of wood, by traditional boatbuilding methods, but were later of wrought iron plates and later of steel. [5]

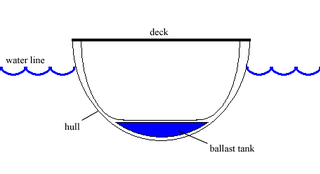

Inside the caisson are ballast spaces, filled with water for stability. An upper space is sealed from the rest and this may contain either water, to sink the caisson firmly into its socket in the dock, or else pumped dry and allowing it to float free.

To seal the gate the enlarged 'keel' of the ship caisson fits closely into a groove in the stonework of the lock opening. Flexible material is attached to this prominent keel and seals the water. Originally rope or oakum packing was used. Modern caissons use neoprene rubber. To make use of the pressure of water acting on the caisson, the seal is not placed on the base of the keel, but on the dry side. Water pressure thus presses the caisson, and seal, firmly against the stonework.

For strength, as the caisson has to resist a considerable pressure of deep water against its air-filled ballast spaces, many caissons still retain a curved or boat-shaped hull. In modern caissons this is usually simplified to a single-curvature arch, rather than a compound curved hull. Some shipyards made a particular trade of building caissons or lock gates. Edward Finch's bridge works was established in Chepstow in the mid 19th century to build ironwork for Brunel's Chepstow Railway Bridge directly above it. As the narrowness and high tides of the River Wye limited the size of the ships that could be built there, they came to specialise in caisson work and supplied most of the docks along the Bristol Channel and beyond. [6]

L'Hermione is a modern replica of the 1779 frigate. She was constructed in one the graving docks at Rochefort, [lower-roman 1] although now fitted with a modern steel caisson. As this is, by modern standards, now a very small dock, the caisson is constructed simply with flat steel sides. When the newly launched ship was to be undocked from the now-flooded dock, the caisson was floated out, L'Hermione towed out and then the caisson replaced by small tugs.

![]() Media related to Maneuvers of the ship caisson of the Louis XV dry dock at the output of the frigate L'Hermione at Wikimedia Commons

Media related to Maneuvers of the ship caisson of the Louis XV dry dock at the output of the frigate L'Hermione at Wikimedia Commons

Ship caissons are slow to operate and so, during the Victorian period, the more efficient 'sliding caisson' (also 'floating-' [lower-roman 2] or 'rolling caisson') was developed. [3] This is a permanent fixture within the dock, like a hinged dock gate, and moves upon a fixed track. The sides of the caisson are vertical, making a narrow rectangular box. Water ballast is used to control its buoyancy, as for the ship caisson, but the floating caisson is then hauled sideways into a recess built into the side of the dock wall. Rolling caissons are a development of sliding caissons fitted with rollers beneath. These do not rely solely on buoyancy to make them portable and so are easier to operate. [7] The caisson may only need to be lifted a few inches to make it movable on its track, which significantly reduces the ballast pumping time compared to a ship caisson. When closing the gate, the track guides it automatically back into place, avoiding the slow manoeuvering with tugs or winches necessary to align a ship caisson. Electrically-operated sliding caissons, installed around 1900, on the entrance of the Zeebrugge Canal to the North Sea could operate within two minutes. [3]

Where a caisson is used, means must be provided to pump ballast water out to float it, to move it in and out of position, and to seal around the caisson when in place. Its operating equipment may be part of the gate, if the gate is frequently used, or general dockside equipment such as pumps and capstans may be used if it is rarely used, such as for a dry dock.

The deep recess alongside the dock is in a high-traffic area and so is covered by iron plates when not in use. Usually these need to be lifted clear before the dock gate can be retracted. When closed, the top of the caisson often provides a convenient bridge across the dock. Unlike the chevron gate, this bridge is straight and so may be used for vehicle traffic. [lower-roman 3] Busy gates, such as for a canal lock, may have dock sides high enough that the caisson can run beneath them. In this case, the roadway on top of the caisson, or its approach ramps, is lowered to fit beneath. [8]

A further advantage of the floating caisson is that, unlike the hinged gate, it does not need space within the dock to allow it to swing. This increases the useful length within the dock, or may permit a smaller and cheaper dock to be constructed. [3]

Floating caissons were sometimes used in places where a high tidal range made conventional chevron gates impractical. [3]

A large system of interconnected docks may sometimes require individual docks to be drained for maintenance. If the connections between docks are made to a standard size, these may be closed off by caissons. As this need is rare, only a few mobile caissons are needed to support an entire dock system. When not in use, the spare caissons are stored floating, out of the way in some other part of the dock.

A lock is a device used for raising and lowering boats, ships and other watercraft between stretches of water of different levels on river and canal waterways. The distinguishing feature of a lock is a fixed chamber in which the water level can be varied; whereas in a caisson lock, a boat lift, or on a canal inclined plane, it is the chamber itself that rises and falls.

A dry dock is a narrow basin or vessel that can be flooded to allow a load to be floated in, then drained to allow that load to come to rest on a dry platform. Dry docks are used for the construction, maintenance, and repair of ships, boats, and other watercraft.

The Falkirk Wheel is a rotating boat lift in Tamfourhill, Falkirk, in central Scotland, connecting the Forth and Clyde Canal with the Union Canal. It reconnects the two canals for the first time since the 1930s. It opened in 2002 as part of the Millennium Link project.

Caisson may refer to:

Bristol Harbour is the harbour in the city of Bristol, England. The harbour covers an area of 70 acres. It is the former natural tidal river Avon through the city but was made into its current form in 1809 when the tide was prevented from going out permanently. A tidal by-pass was dug for 2 miles through the fields of Bedminster for the river, known as the "River Avon New Cut", "New Cut", or simply "The Cut". It is often called the Floating Harbour as the water level remains constant and it is not affected by the state of the tide on the river in the Avon Gorge, The New Cut or the natural river southeast of Temple Meads to its source.

Sharpness is an English port in Gloucestershire, one of the most inland in Britain, and eighth largest in the South West England region. It is on the River Severn at grid reference SO669027, at a point where the tidal range, though less than at Avonmouth downstream, is still large.

In geotechnical engineering, a caisson is a watertight retaining structure used, for example, to work on the foundations of a bridge pier, for the construction of a concrete dam, or for the repair of ships.

A ballast tank is a compartment within a boat, ship or other floating structure that holds water, which is used as ballast to provide hydrostatic stability for a vessel, to reduce or control buoyancy, as in a submarine, to correct trim or list, to provide a more even load distribution along the hull to reduce structural hogging or sagging stresses, or to increase draft, as in a semi-submersible vessel or platform, or a SWATH, to improve seakeeping. Using water in a tank provides easier weight adjustment than the stone or iron ballast used in older vessels, and makes it easy for the crew to reduce a vessel's draft when it enters shallower water, by temporarily pumping out ballast. Airships use ballast tanks mainly to control buoyancy and correct trim.

The caisson lock is a type of canal lock in which a narrowboat is floated into a sealed watertight box and raised or lowered between two different canal water levels. It was invented in the late 18th century as a solution to the problem posed by the excessive demand for water when conventional locks were used to raise and lower canal boats through large height differences. Such locks, each of which would only raise and lower boats through small height differences of a few feet, would not suffice when large height differences had to be tackled nor when water was in short supply. The caisson was thought to be one solution, although it transpired that the technology of the day was not capable of achieving this type of construction economically.

Karl Johanslussen is a lock and a sluice, along the Söderström river connecting and controlling the flood discharge between Riddarfjärden, the easternmost part of Lake Mälaren, and Saltsjön, the section of the Baltic Sea reaching into central Stockholm, Sweden. The lock is 75 metres long, 10 metres wide and 3.90 metres deep. The maximum height is 3.8 metres. The lock is closed from 2016 to 2021 due to large reconstruction works in the area.

The Underfall Yard is a historic boatyard on Spike Island serving Bristol Harbour in England.

King George V Graving Dock, also known as No. 7 Dry Dock, is a former dry dock situated in Southampton's Western Docks. It was designed by F.E. Wentworth-Shields and constructed by John Mowlem & Company and Edmund Nuttall Sons & Company. It was formally opened by King George V and Queen Mary on 26 July 1933 although the final construction work was only complete the following year. At the time of construction it was the largest graving dock in the world, a status it retained for nearly thirty years.

The Royers lock is a tidal lock located in Belgium, giving access to the right bank docks in the Port of Antwerp and the Albert Canal. Although it was built for sea-going vessels, it is now mostly used by riverboats.

A floating dock, floating harbour or wet dock is a dock alongside a tidal waterway which maintains a 'constant' level, despite the changing tides.

An auxiliary floating drydock is a type of US Navy auxiliary floating dry dock. Floating dry docks are able to submerge underwater and to be placed under a ship in need of repair below the water line. Water is then pumped out of the floating dry dock, raising the ship out of the water. The ship becomes blocked on the deck of the floating dry dock for repair. Most floating dry docks have no engine and are towed by tugboats to their destinations. Floating dry docks come in different sizes to accommodate varying ship sizes, while large floating dry docks come in sections and can be combined to increase their size and lift power. Ballast pontoon tanks are flooded with water to submerge or pumped dry to raise the ship.

USS ARD-1 was an auxiliary repair dock serving with the United States Navy during World War II as Auxiliary floating drydock. ARD-1 was built by the Pacific Bridge Company and completed in September 1934. ARD-1 was commissioned at Alameda, California on 19 December 1935 then towed to San Diego, California. ARD-1 was the first in her class of self-sustaining, ship hull shape ship repair docks. ARD-1 was able to repair ships in a Naval fleet in remote locations.

Hellevoetsluis Dry Dock is a historic double dry dock in Hellevoetsluis, Netherlands. It was constructed between 1798 and 1822 under the direction of Jan Blanken, and was part of the former Rijkswerf Hellevoetsluis. The dock is one of the rare surviving double dry docks. It is a national monument, and is in operation as part of the maritime attraction 'Dry Dock Jan Blanken',.

Willemsoord Dry Dock I is a historic dry dock in Willemsoord, Den Helder, Netherlands. It was constructed from 1813 till 1822, under the direction of Jan Blanken, and was part of the former Rijkswerf Willemsoord.

Middelburg Drydock is a former dry dock in Middelburg, Netherlands. The Dock chamber still exists.