A cam and groove coupling, also called a camlock fitting, is a form of hose coupling. This kind of coupling is popular because it is a simple and reliable means of connecting and disconnecting hoses quickly and without tools.

A cam and groove coupling, also called a camlock fitting, is a form of hose coupling. This kind of coupling is popular because it is a simple and reliable means of connecting and disconnecting hoses quickly and without tools.

Traditionally manufactured to US Military Specification MIL-C-27487, this specification covered the dimensions and machining tolerances, materials, closing torque, part numbers, pressure ratings, finish, inspection procedures and packing requirements. Compliance to this specification ensured inter-changeability of parts from different manufacturers. In 1998, the specification A-A-59326 replaced MIL-C-27487. In Europe the standard BS EN 14420-7 applies as well as the German DIN 2828 standard. Products produced to DIN 2828 are interchangeable with those made to the original MIL-C-27487 but have differences in the hose tail design, thread, part number and other details. [1]

The cams at the end of each lever on the female end align with a circumferential groove on the male end. When the levers are rotated to the locked position, they pull the male end into the female socket, creating a tight seal against a gasket within the female socket. The arms lock into position using over-center geometry, preventing accidental decoupling. Further, lever safety pins are common features for additional security, and female-end "self-locking" levers are also available. Because the groove is cut all the way around the male end, there is no specific rotational alignment necessary to couple, as there would be with threaded connectors, and there is no opportunity for cross-threading. This results in a fast, error-resistant coupling operation. Because the compression between the two fittings is limited by the size of the cams on the end of the levers and the rotation of the levers themselves, there is also no possibility of over- or under-tightening the fitting; the pressure against the sealing gasket is effectively constant from one coupling operation to the next, reducing possibility of leaks.

Cam and groove fittings are commonly available in several materials, including stainless steel, aluminum, brass, and polypropylene. [2] Because there are no threads to become fouled, cam and groove couplings are popular in moderately dirty environments, such as septic tank pump trucks and chemical or fuel tanker trucks. The system is especially well suited to a situation where frequent changes of hoses are required, such as for petroleum trucks, etc. As examples of industrial application, cam and groove fittings can be used in a system where rapid filling of chemical drums takes place, or by factories that have needs of dye, paint, and ink medium transfers.

Note: Cam and Groove couplings are not recommended for any type of compressed gas service, including steam or air.

Generally speaking, the most common types of cam and groove coupling are the following types. The letter codes are the common designations, while the roman numeral codes come from the GSA CID A-A-59326 [3] standard:

Apart from these basic types, the hose/pipe connection side of a cam and groove coupler can be of various other types such as with a flange, for butt welding to a container, for truck use with a sight glass, etc.

These couplings are available in the following diameters:

| Inches | Millimetres |

|---|---|

| 1⁄2 | 13 |

| 3⁄4 | 19 |

| 1 | 25 |

| 1+1⁄4 | 32 |

| 1+1⁄2 | 38 |

| 2 | 51 |

| 2+1⁄2 | 64 |

| 3 | 76 |

| 4 | 102 |

| 5 | 127 |

| 6 | 152 |

| 7 | 178 |

| 8 | 203 |

A flange is a protruded ridge, lip or rim, either external or internal, that serves to increase strength ; for easy attachment/transfer of contact force with another object ; or for stabilizing and guiding the movements of a machine or its parts. Flanges are often attached using bolts in the pattern of a bolt circle.

The BNC connector is a miniature quick connect/disconnect radio frequency connector used for coaxial cable. It is designed to maintain the same characteristic impedance of the cable, with 50 ohm and 75 ohm types being made. It is usually applied for video and radio frequency connections up to about 2 GHz and up to 500 volts. The connector has a twist to lock design with two lugs in the female portion of the connector engaging a slot in the shell of the male portion. The type was introduced on military radio equipment in the 1940s and has since become widely applied in radio systems, and is a common type of video connector. Similar radio-frequency connectors differ in dimensions and attachment features, and may allow for higher voltages, higher frequencies, or three-wire connections.

Storz is a type of hose coupling invented by Carl August Guido Storz in 1882 and patented in Switzerland in 1890, and patented in the U.S. in 1893 that connects using interlocking hooks and flanges. It was first specified in standard FEN 301-316, and has been used by German fire brigades since 1933. Amongst other uses, it has been widely employed on fire hoses in firefighting applications. It is the standard coupling on fire hoses in Portugal, Denmark, Slovenia, Germany, Austria, Switzerland, Sweden, the Netherlands, Poland, Czechia, Israel, Croatia, Serbia, Bosnia & Herzegovina, Macedonia, Montenegro and Greece. It is also one of the standard couplings on fire hoses in Australia and the United States.

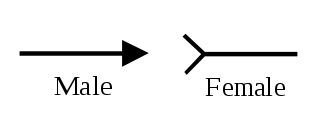

In electrical and mechanical trades and manufacturing, each half of a pair of mating connectors or fasteners is conventionally assigned the designation male or female. The female connector is generally a receptacle that receives and holds the male connector. Alternative terminology such as plug and socket or jack are sometimes used, particularly for electrical connectors.

This is a glossary of firefighting equipment.

A garden hose, hosepipe, or simply hose is a flexible tube used to convey water. There are a number of common attachments available for the end of the hose, such as sprayers and sprinklers. Hoses are usually attached to a hose spigot or tap.

In plumbing and piping, a nipple is a fitting, consisting of a short piece of pipe, usually provided with a male pipe thread at each end, for connecting two other fittings.

A hose coupling is a connector on the end of a hose to connect it with another hose or with a tap or a hose appliance, such as an irrigation sprinkler. It is usually made of steel, brass, stainless steel, aluminium or plastic.

British Standard Pipe (BSP) is a set of technical standards for screw threads that has been adopted internationally for interconnecting and sealing pipes and fittings by mating an external (male) thread with an internal (female) thread. It has been adopted as standard in plumbing and pipe fitting, except in North America, where NPT and related threads are used.

A threaded pipe is a pipe with screw-threaded ends for assembly.

In piping and plumbing, a coupling is a very short length of pipe or tube, with a socket at one or both ends that allows two pipes or tubes to be joined, welded (steel), brazed or soldered together.

A fitting or adapter is used in pipe systems to connect sections of pipe or tube, adapt to different sizes or shapes, and for other purposes such as regulating fluid flow. These fittings are used in plumbing to manipulate the conveyance of fluids such as water for potatory, irrigational, sanitary, and refrigerative purposes, gas, petroleum, liquid waste, or any other liquid or gaseous substances required in domestic or commercial environments, within a system of pipes or tubes, connected by various methods, as dictated by the material of which these are made, the material being conveyed, and the particular environmental context in which they will be used, such as soldering, mortaring, caulking, Plastic welding, welding, friction fittings, threaded fittings, and compression fittings.

Ground glass joints are used in laboratories to quickly and easily fit leak-tight apparatus together from interchangeable commonly available parts. For example, a round bottom flask, Liebig condenser, and oil bubbler with ground glass joints may be rapidly fitted together to reflux a reaction mixture. This is a large improvement compared with older methods of custom-made glassware, which was time-consuming and expensive, or the use of less chemical resistant and heat resistant corks or rubber bungs and glass tubes as joints, which took time to prepare as well.

Electrical or fiber-optic connectors used by U.S. Department of Defense were originally developed in the 1930s for severe aeronautical and tactical service applications, and the Type "AN" (Army-Navy) series set the standard for modern military circular connectors. These connectors, and their evolutionary derivatives, are often called Military Standard, "MIL-STD", or (informally) "MIL-SPEC" or sometimes "MS" connectors. They are now used in aerospace, industrial, marine, and even automotive commercial applications.

Camlock or cam lock may refer to:

For hoses and piping, a quick connect fitting, also called a push fitting is a coupling used to provide a fast, make-or-break connection of gas or liquid transfer lines. Operated by hand, quick connect fittings replace threaded or flanged connections, which require wrenches. When equipped with self-sealing valves, quick connect fittings will, upon disconnection, automatically contain any fluid in the line.

Also known as pneumatic couplings, quick disconnects, air couplers, quick connect couplers, and quick couplers, hand-operable air-line fittings allow manual disconnection of gas supply lines, including compressed air and breathable air. Most fittings do not have regional standardization but have become de facto standards through popular adoption.

ISO 2852Stainless steel clamp pipe couplings for the food industry was an international standard that defines a non-permanent sanitary food-grade piping interconnect method, commonly used in the food processing industry and with dairy farm equipment.

Despite fire hose and hydrant coupler standardization efforts that are at least 144 years old, there remain significant areas in Canada, the United States, and Mexico that use fire hose and hydrant threads and other couplings that are incompatible with those used by neighboring fire departments. This is notable because the first fire hydrant was invented by Manhattan fire fighter George Smith in 1817, making these devices 200 years old.

{{cite web}}: CS1 maint: numeric names: authors list (link)