A sight glass or water gauge is a type of level sensor, a transparent tube through which the operator of a tank or boiler can observe the level of liquid contained within.

A sight glass or water gauge is a type of level sensor, a transparent tube through which the operator of a tank or boiler can observe the level of liquid contained within.

Simple sight glasses may be just a plastic or glass tube connected to the bottom of the tank at one end and the top of the tank at the other. The level of liquid in the sight glass will be the same as the level of liquid in the tank. Today, however, sophisticated float switches have replaced sight glasses in many such applications.

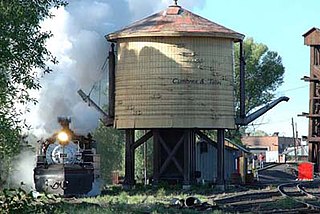

If the liquid is hazardous or under pressure, more sophisticated arrangements must be made. In the case of a boiler, the pressure of the water below and the steam above is equal, so any change in the water level will be seen in the gauge. The transparent tube (the “glass” itself) may be mostly enclosed within a metal or toughened glass shroud to prevent it from being damaged through scratching or impact and offering protection to the operators in the case of breakage. This usually has a patterned backplate to make the magnifying effect of the water in the tube more obvious and so allow for easier reading. In some locomotives where the boiler is operated at very high pressures, the tube itself would be made of metal-reinforced toughened glass. [1] It is important to keep the water at the specified level, otherwise the top of the firebox will be exposed, creating an overheat hazard and causing damage and possibly catastrophic failure.

To check that the device is offering a correct reading and the connecting pipes to the boiler are not blocked by scale, the water level needs to be “bobbed” by quickly opening the taps in turn and allowing a brief spurt of water through the drain cock. [2]

The National Board of Boiler and Pressure Vessel Inspectors recommends a daily testing procedure described by the American National Standards Institute, chapter 2 part I-204.3 water level gauge. While not strictly required, this procedure is designed to allow an operator to safely verify that all parts of the sight glass are operating correctly and have free flowing connections to the boiler necessary for proper operation.

The gauge glass on a boiler needs to be inspected periodically and replaced if it is seen to have worn thin in the vicinity of the gland nuts, but a failure in service can still occur. Drivers are expected to carry two or three glass tubes, pre-cut to the required length, together with hemp or rubber seals, to replace the tubes on the road. [1] Familiarity with this disquieting occurrence was considered so important that a glass would often be smashed deliberately while a trainee driver was on the footplate, to give him practice in fitting a new tube. [3] Although automatic ball valves are fitted in the mounts to limit the release of steam and scalding water, these can fail through accumulation of limescale. It was standard procedure to hold the coal scoop in front of the face while the other hand, holding the cap for protection, reached to turn off the valves at both ends of the glass.

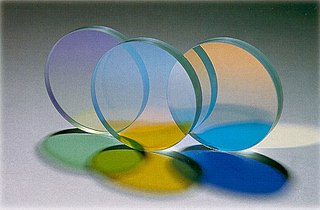

A reflex gauge is more complex in construction but can give a clearer distinction between gas (steam) and liquid (water). Instead of containing the media in a glass tube, the gauge consists of a vertically oriented slotted metal body with a strong glass plate mounted on the open side of the slot facing the operator. The rear of the glass, in contact with the media, has grooves moulded into its surface, running vertically. The grooves form a zig-zag pattern with 90° angles. Incident light entering the glass is refracted at the rear surface in contact with the media. In the region that is contact with the gas, most of the light is reflected from the surface of one groove to the next and back towards the operator, appearing silvery white. In the region that is in contact with the liquid, most of the light is refracted into the liquid causing this region to appear almost black to the operator. Well-known makes of reflex gauge are Clark-Reliance, IGEMA, TGI Ilmadur, Penberthy, Jerguson, Klinger, Cesare-Bonetti and Kenco. Due to the caustic nature of boiler anti-scaling treatments ("water softeners"), reflex gauges tend to become relatively rapidly etched by the water and lose their effectiveness at displaying the liquid level. Therefore, bi-colour gauges are recommended for certain types of boiler, particularly those operating at pressure above 60 bar.

A bi-colour gauge is generally preferred for caustic media in order to afford protection to the glass. The gauge consists of a vertically oriented slotted metal body with a strong plain glass to the front and the rear. The front and rear body surfaces are in non-parallel vertical planes. Behind the gauge body are light sources with two quite different wavelengths, typically red and green. Due to the different refraction of the red and green light, the liquid region appears green to the operator, while the gas region appears red. Unlike the reflex gauge, the glass has a plane surface which it does not need to be in direct contact with the media and can be protected with a layer of a caustic-resistant transparent material such as silica. Well-known manufacturers of the highest quality Bi-Colour Level Gauges are Clark-Reliance, Klinger, FPS-Aquarian, IGEMA and Quest-Tec

In a magnetic indicator is a float on the surface of the liquid contains a permanent magnet. The liquid is contained in a chamber of strong, non-magnetic material, avoiding the use of glass. The level indicator consists of a number of pivoting magnetic vanes arranged one above the other and placed close to the chamber containing the float. The two faces of the vanes are differently coloured. As the magnet passes up and down behind the vanes it cause them to rotate, displaying one colour for the region containing the liquid and another for the region containing gas. Magnetic indicators are stated in various manufacturers' literature to be most suitable for very high pressure and / or temperature and for aggressive liquids.

The first locomotive to be fitted with the device was built in 1829 by John Rastrick at his Stourbridge works. [4]

Industrial observational instruments have changed with industry itself. More structurally sophisticated than the water gauge, the contemporary sight glass — also called the sight window or sight port — can be found on the media vessel at chemical plants and in other industrial settings, including pharmaceutical, food, beverage and bio gas plants. [5] Sight glasses enable operators to visually observe processes inside tanks, pipes, reactors and vessels.

The modern industrial sight glass is a glass disk held between two metal frames, which are secured by bolts and gaskets, or the glass disc is fused to the metal frame during manufacture. The glass used for this purpose is either soda lime glass or borosilicate glass, and the metal, usually a type of stainless steel, is chosen for desired properties of strength. Borosilicate glass is superior to other formulations in terms of chemical corrosion resistance and temperature tolerance, as well as transparency. [6]

Fused sight glasses are also called mechanically prestressed glass, because the glass is strengthened by compression of the metal ring. Heat is applied to a glass disc and its surrounding steel ring, causing a fusion of the materials. [7] As the steel cools, it contracts, compressing the glass and making it resistant to tension. Because glass typically breaks under tension, mechanically prestressed glass is unlikely to break and endanger workers. The strongest sight glasses are made with borosilicate glass, because of the greater difference in its coefficient of expansions.

Glass is an amorphous (non-crystalline) solid. Because it is often transparent and chemically inert, glass has found widespread practical, technological, and decorative use in window panes, tableware, and optics. Some common objects made of glass are named after the material, e.g. "glass", "glasses", "magnifying glass".

A boiler is a closed vessel in which fluid is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, central heating, boiler-based power generation, cooking, and sanitation.

A steam locomotive is a locomotive that provides the force to move itself and other vehicles by means of the expansion of steam. It is fuelled by burning combustible material to heat water in the locomotive's boiler to the point where it becomes gaseous and its volume increases 1,700 times. Functionally, it is a steam engine on wheels.

In the field of optics, transparency is the physical property of allowing light to pass through the material without appreciable scattering of light. On a macroscopic scale, the photons can be said to follow Snell's law. Translucency allows light to pass through but does not necessarily follow Snell's law; the photons can be scattered at either of the two interfaces, or internally, where there is a change in the index of refraction. In other words, a translucent material is made up of components with different indices of refraction. A transparent material is made up of components with a uniform index of refraction. Transparent materials appear clear, with the overall appearance of one color, or any combination leading up to a brilliant spectrum of every color. The opposite property of translucency is opacity. Other categories of visual appearance, related to the perception of regular or diffuse reflection and transmission of light, have been organized under the concept of cesia in an order system with three variables, including transparency, translucency and opacity among the involved aspects.

Fused quartz, fused silica or quartz glass is a glass consisting of almost pure silica (silicon dioxide, SiO2) in amorphous (non-crystalline) form. This differs from all other commercial glasses, such as soda-lime glass, lead glass, or borosilicate glass, in which other ingredients are added which change the glasses' optical and physical properties, such as lowering the melt temperature, the spectral transmission range, or the mechanical strength. Fused quartz, therefore, has high working and melting temperatures, making it difficult to form and less desirable for most common applications, but is much stronger, more chemically resistant, and exhibits lower thermal expansion, making it more suitable for many specialized uses such as lighting and scientific applications.

A fire-tube boiler is a type of boiler invented in 1828 by Mark Seguin, in which hot gases pass from a fire through one or more tubes running through a sealed container of water. The heat of the gases is transferred through the walls of the tubes by thermal conduction, heating the water and ultimately creating steam.

In a steam engine, the firebox is the area where the fuel is burned, producing heat to boil the water in the boiler. Most are somewhat box-shaped, hence the name. The hot gases generated in the firebox are pulled through a rack of tubes running through the boiler.

Borosilicate glass is a type of glass with silica and boron trioxide as the main glass-forming constituents. Borosilicate glasses are known for having very low coefficients of thermal expansion, making them more resistant to thermal shock than any other common glass. Such glass is subjected to less thermal stress and can withstand temperature differentials without fracturing of about 165 °C (300 °F). It is commonly used for the construction of reagent bottles and flasks, as well as lighting, electronics, and cookware. For many other applications, soda-lime glass is more common.

A boiler explosion is a catastrophic failure of a boiler.

Level sensors detect the level of liquids and other fluids and fluidized solids, including slurries, granular materials, and powders that exhibit an upper free surface. Substances that flow become essentially horizontal in their containers because of gravity whereas most bulk solids pile at an angle of repose to a peak. The substance to be measured can be inside a container or can be in its natural form. The level measurement can be either continuous or point values. Continuous level sensors measure level within a specified range and determine the exact amount of substance in a certain place, while point-level sensors only indicate whether the substance is above or below the sensing point. Generally the latter detect levels that are excessively high or low.

Boiler water is liquid water within a boiler, or in associated piping, pumps and other equipment, that is intended for evaporation into steam. The term may also be applied to raw water intended for use in boilers, treated boiler feedwater, steam condensate being returned to a boiler, or boiler blowdown being removed from a boiler.

A fusible plug is a threaded cylinder of metal, usually bronze, brass or gunmetal, with a tapered hole drilled completely through its length. This hole is sealed with a metal of low melting point that flows away if a predetermined high temperature is reached. The initial use of the fusible plug was as a safety precaution against low water levels in steam engine boilers, but later applications extended its use to other closed vessels, such as air conditioning systems and tanks for transporting corrosive or liquefied petroleum gases.

Boiler feedwater is the water which is supplied to a boiler. The feed water is put into the steam drum from a feed pump. In the steam drum the feed water is then turned into steam from the heat. After the steam is used, it is then dumped to the main condenser. From the condenser, it is then pumped to the deaerated feed tank. From this tank it then goes back to the steam drum to complete its cycle. The feedwater is never open to the atmosphere. This cycle is known as a closed system or Rankine cycle.

A boiler or steam generator is a device used to create steam by applying heat energy to water. Although the definitions are somewhat flexible, it can be said that older steam generators were commonly termed boilers and worked at low to medium pressure but, at pressures above this, it is more usual to speak of a steam generator.

Glass-to-metal seals are a type of mechanical seal which joins glass and metal surfaces. They are very important elements in the construction of vacuum tubes, electric discharge tubes, incandescent light bulbs, glass-encapsulated semiconductor diodes, reed switches, glass windows in metal cases, and metal or ceramic packages of electronic components.

A glass stirring rod, glass rod, stirring rod or stir rod is a piece of laboratory equipment used to mix chemicals. They are usually made of solid glass, about the thickness and slightly longer than a drinking straw, with rounded ends.

Porous glass is glass that includes pores, usually in the nanometre- or micrometre-range, commonly prepared by one of the following processes: through metastable phase separation in borosilicate glasses (such as in their system SiO2-B2O3-Na2O), followed by liquid extraction of one of the formed phases; through the sol-gel process; or simply by sintering glass powder.

Boilers for generating steam or hot water have been designed in countless shapes, sizes and configurations. An extensive terminology has evolved to describe their common features. This glossary provides definitions for these terms.