A steam engine is a heat engine that performs mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a cylinder. This pushing force can be transformed, by a connecting rod and crank, into rotational force for work. The term "steam engine" is generally applied only to reciprocating engines as just described, not to the steam turbine. Steam engines are external combustion engines, where the working fluid is separated from the combustion products. The ideal thermodynamic cycle used to analyze this process is called the Rankine cycle. In general usage, the term steam engine can refer to either complete steam plants, such as railway steam locomotives and portable engines, or may refer to the piston or turbine machinery alone, as in the beam engine and stationary steam engine.

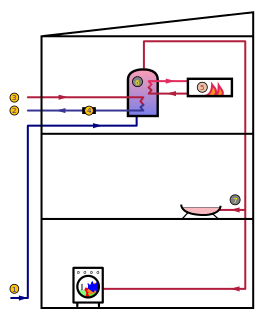

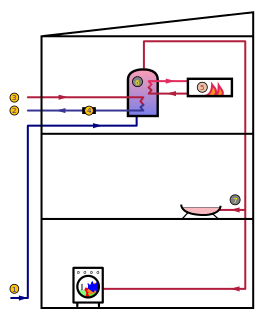

A boiler is a closed vessel in which fluid is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, central heating, boiler-based power generation, cooking, and sanitation.

A power station, also referred to as a power plant and sometimes generating station or generating plant, is an industrial facility for the generation of electric power. Power stations are generally connected to an electrical grid.

Spot welding is a type of electric resistance welding used to weld various sheet metal products, through a process in which contacting metal surface points are joined by the heat obtained from resistance to electric current.

A thermostat is a regulating device component which senses the temperature of a physical system and performs actions so that the system's temperature is maintained near a desired setpoint.

Water heating is a heat transfer process that uses an energy source to heat water above its initial temperature. Typical domestic uses of hot water include cooking, cleaning, bathing, and space heating. In industry, hot water and water heated to steam have many uses.

On a ship, the engine room (ER) is the compartment where the machinery for marine propulsion is located. To increase a vessel's safety and chances of surviving damage, the machinery necessary for the ship's operation may be segregated into various spaces. The engine room is generally the largest physical compartment of the machinery space. It houses the vessel's prime mover, usually some variations of a heat engine. On some ships, there may be more than one engine room, such as forward and aft, or port or starboard engine rooms, or may be simply numbered.

An injector is a system of ducting and nozzles used to direct the flow of a high-pressure fluid in such a way that a lower pressure fluid is entrained in the jet and carried through a duct to a region of higher pressure. It is a fluid-dynamic pump with no moving parts except a valve to control inlet flow. A steam injector is a typical application of the principle used to deliver cold water to a boiler against its own pressure, using its own live or exhaust steam, replacing any mechanical pump. When first developed, its operation was intriguing because it seemed paradoxical, almost like perpetual motion, but it was later explained using thermodynamics. Other types of injector may use other pressurised motive fluids such as air.

Plasma arc welding (PAW) is an arc welding process similar to gas tungsten arc welding (GTAW). The electric arc is formed between an electrode and the workpiece. The key difference from GTAW is that in PAW, the electrode is positioned within the body of the torch, so the plasma arc is separated from the shielding gas envelope. The plasma is then forced through a fine-bore copper nozzle which constricts the arc and the plasma exits the orifice at high velocities and a temperature approaching 28,000 °C (50,000 °F) or higher.

A thermal power station is a type of power station in which heat energy is converted to electrical energy. In a steam-generating cycle heat is used to boil water in a large pressure vessel to produce high-pressure steam, which drives a steam turbine connected to an electrical generator. The low-pressure exhaust from the turbine enters a steam condenser where it is cooled to produce hot condensate which is recycled to the heating process to generate more high pressure steam. This is known as a Rankine cycle.

A deaerator is a device that removes oxygen and other dissolved gases from liquids and pumpable compounds.

The steam-electric power station is a power station in which the electric generator is steam driven. Water is heated, turns into steam and spins a steam turbine which drives an electrical generator. After it passes through the turbine, the steam is condensed in a condenser. The greatest variation in the design of steam-electric power plants is due to the different fuel sources.

A boiler feedwater pump is a specific type of pump used to pump feedwater into a steam boiler. The water may be freshly supplied or returning condensate produced as a result of the condensation of the steam produced by the boiler. These pumps are normally high pressure units that take suction from a condensate return system and can be of the centrifugal pump type or positive displacement type.

An oil burner is a heating device which burns #1, #2 and #6 heating oils, diesel fuel or other similar fuels. In the United States ultra low #2 diesel is the common fuel used. It is dyed red to show that it is road-tax exempt. In most markets of the United States heating oil is the same specification of fuel as on-road un-dyed diesel.

An electric steam boiler is a type of boiler where the steam is generated using electricity, rather than through the combustion of a fuel source. Such boilers are used to generate steam for process purposes in many locations, for example laundries, food processing factories and hospitals. Although they are more expensive to run than gas-fired or oil-fired boilers they are popular because of their simplicity and ease of use. Because of the large currents required, they are normally run from a three-phase electricity supply. They convert electrical energy into thermal energy with almost 100% efficiency but the overall thermal efficiency is variable, depending on the efficiency with which the electricity is generated.

An electric boiler is a device that uses electrical energy to boil water.

The Glossary of fuel cell terms lists the definitions of many terms used within the fuel cell industry. The terms in this fuel cell glossary may be used by fuel cell industry associations, in education material and fuel cell codes and standards to name but a few.

Electrical resistance heating (ERH) is an intensive in situ environmental remediation method that uses the flow of alternating current electricity to heat soil and groundwater and evaporate contaminants. Electric current is passed through a targeted soil volume between subsurface electrode elements. The resistance to electrical flow that exists in the soil causes the formation of heat; resulting in an increase in temperature until the boiling point of water at depth is reached. After reaching this temperature, further energy input causes a phase change, forming steam and removing volatile contaminants. ERH is typically more cost effective when used for treating contaminant source areas.

Tankless water heaters — also called instantaneous, continuous flow, inline, flash, on-demand, or instant-on water heaters — are water heaters that instantly heat water as it flows through the device, and do not retain any water internally except for what is in the heat exchanger coil. Copper heat exchangers are preferred in these units because of their high thermal conductivity and ease of fabrication.

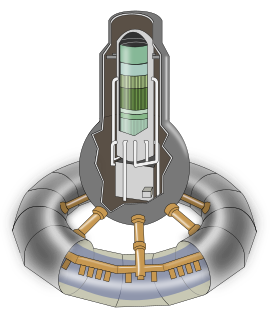

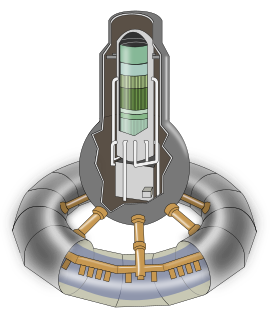

General Electric's BWR product line of boiling water reactors represents the designs of a relatively large (~18%) percentage of the commercial fission reactors around the world.