Stephenson's Rocket is an early steam locomotive of 0-2-2 wheel arrangement. It was built for and won the Rainhill Trials of the Liverpool and Manchester Railway (L&MR), held in October 1829 to show that improved locomotives would be more efficient than stationary steam engines.

A tank locomotive or tank engine is a steam locomotive that carries its water in one or more on-board water tanks, instead of a more traditional tender. Most tank engines also have bunkers to hold fuel; in a tender-tank locomotive a tender holds some or all of the fuel, and may hold some water also.

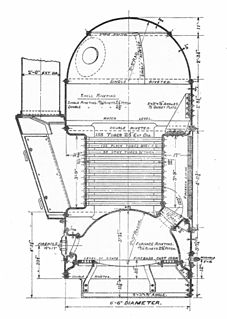

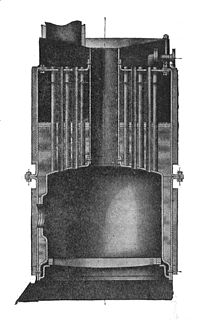

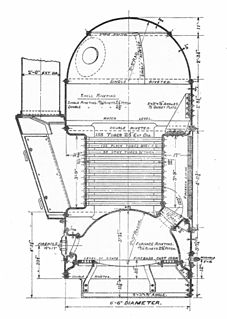

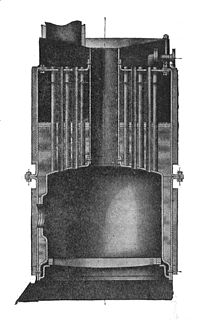

A fire-tube boiler is a type of boiler in which hot gases pass from a fire through one or more tubes running through a sealed container of water. The heat of the gases is transferred through the walls of the tubes by thermal conduction, heating the water and ultimately creating steam.

In a steam engine, the firebox is the area where the fuel is burned, producing heat to boil the water in the boiler. Most are somewhat box-shaped, hence the name. The hot gases generated in the firebox are pulled through a rack of tubes running through the boiler.

A smokebox is one of the major basic parts of a steam locomotive exhaust system. Smoke and hot gases pass from the firebox through tubes where they pass heat to the surrounding water in the boiler. The smoke then enters the smokebox, and is exhausted to the atmosphere through the chimney. Early locomotives had no smokebox and relied on a long chimney to provide natural draught for the fire but smokeboxes were soon included in the design for two main reasons. Firstly and most importantly, the blast of exhaust steam from the cylinders, when directed upwards through an airtight smokebox with an appropriate design of exhaust nozzle, effectively draws hot gases through the boiler tubes and flues and, consequently, fresh combustion air into the firebox. Secondly, the smokebox provides a convenient collection point for ash and cinders ("char") drawn through the boiler tubes, which can be easily cleaned out at the end of a working day. Without a smokebox, all char must pass up the chimney or will collect in the tubes and flues themselves, gradually blocking them.

The blastpipe is part of the exhaust system of a steam locomotive that discharges exhaust steam from the cylinders into the smokebox beneath the chimney in order to increase the draught through the fire.

The Long Boiler locomotive was the object of a patent by Robert Stephenson and the name became synonymous with the pattern. Its defining feature is that the firebox is placed behind the rearmost driving axle. This gives a long boiler barrel, with long fire-tubes. There is thus a generous heating surface area, giving a boiler that is both powerful and efficient.

The Yorkshire Patent Steam Wagon Co. was a steam wagon manufacturer in Leeds, England. They produced their first wagon in 1901. Their designs had a novel double-ended transverse boiler. In 1911 the company's name was changed to Yorkshire Commercial Motor Co., but reverted to Yorkshire Patent Steam Wagon Co. in 1922. Steam wagon production ceased in 1937, and the company was finally dissolved in 1993.

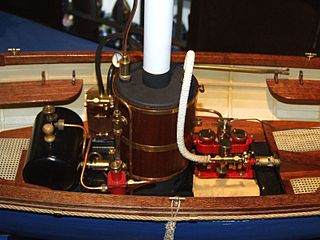

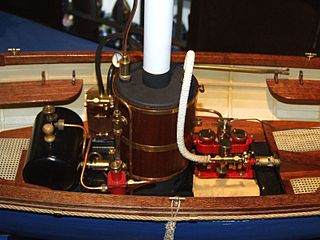

A vertical boiler is a type of fire-tube or water-tube boiler where the boiler barrel is oriented vertically instead of the more common horizontal orientation. Vertical boilers were used for a variety of steam-powered vehicles and other mobile machines, including early steam locomotives.

The London Midland and Scottish Railway (LMS) 2 and 2A boilered 4-6-0 locomotives were express passenger 4-6-0 steam locomotives. In 1935 W.A. Stanier, Chief Mechanical Engineer of the LMS, ordered the rebuilding of the unique experimental high pressure compound locomotive 6399 Fury. The Schmidt-Henschel boiler was replaced with a tapered boiler, with a drumhead smokebox, designated type 2. The type 2 boiler had a tube surface of 1669 square feet, formed by tubes 2⅛ inches in diameter and 14' 3" long. It was fitted with a 28 row superheater with 360 square feet of heating surface. The superheater elements, 1⅛ inch in diameter, were fitted into flue tubes 5⅛ inches diameter. On test the boiler performed poorly, heat transfer to the water being inadequate because the hot gases from the firebox passed too rapidly through the tubes to the smokebox. The rapid passage of gas was indicated by too high a temperature in the smokebox, and the choking of the smokebox by excessive char carried through from the firebox. The boiler was re-tubed with 180 smaller tubes 1⅞ inches diameter, and with superheater elements 1¼ inch diameter. The single blastpipe was replaced with a double blastpipe and chimney to provide adequate gas velocity in the smokebox. This, combined with the increased rate of evaporation provided by the re-tubing, improved the performance of the boiler substantially.

The Lancashire and Yorkshire Railway (L&YR) operated two classes of twenty steam railmotors in total.

A shell or flued boiler is an early and relatively simple form of boiler used to make steam, usually for the purpose of driving a steam engine. The design marked a transitional stage in boiler development, between the early haystack boilers and the later multi-tube fire-tube boilers. A flued boiler is characterized by a large cylindrical boiler shell forming a tank of water, traversed by one or more large flues containing the furnace. These boilers appeared around the start of the 19th century and some forms remain in service today. Although mostly used for static steam plants, some were used in early steam vehicles, railway locomotives and ships.

A vertical boiler with horizontal fire-tubes is a type of small vertical boiler, used to generate steam for small machinery. It is characterised by having many narrow fire-tubes, running horizontally.

Boilers for generating steam or hot water have been designed in countless shapes, sizes and configurations. An extensive terminology has evolved to describe their common features. This glossary provides definitions for these terms.

The Sentinel boiler was a design of vertical boiler, fitted to the numerous steam waggons built by the Sentinel Waggon Works.

Three-drum boilers are a class of water-tube boiler used to generate steam, typically to power ships. They are compact and of high evaporative power, factors that encourage this use. Other boiler designs may be more efficient, although bulkier, and so the three-drum pattern was rare as a land-based stationary boiler.

A vertical fire-tube boiler or vertical multitubular boiler is a vertical boiler where the heating surface is composed of multiple small fire-tubes, arranged vertically.

The chimney is the part of a steam locomotive through which smoke leaves the boiler. Steam locomotive exhaust systems typically vent cylinder exhaust through the chimney to enhance draught through the boiler. Chimneys are designed to carry exhaust steam and smoke clear of the driver's line of sight while remaining short enough to clear overhead structures. Some chimneys included features to avoid dispersing sparks.

The steam locomotive exhaust system consists of those parts of a steam locomotive which together discharge exhaust steam from the cylinders in order to increase the draught through the fire. It usually consists of the blastpipe, smokebox, and chimney, although later designs also include second and third stage nozzles.

The South African Railways Class 10B 4-6-2 of 1910 was a steam locomotive from the pre-Union era in Transvaal.